Product Specifications

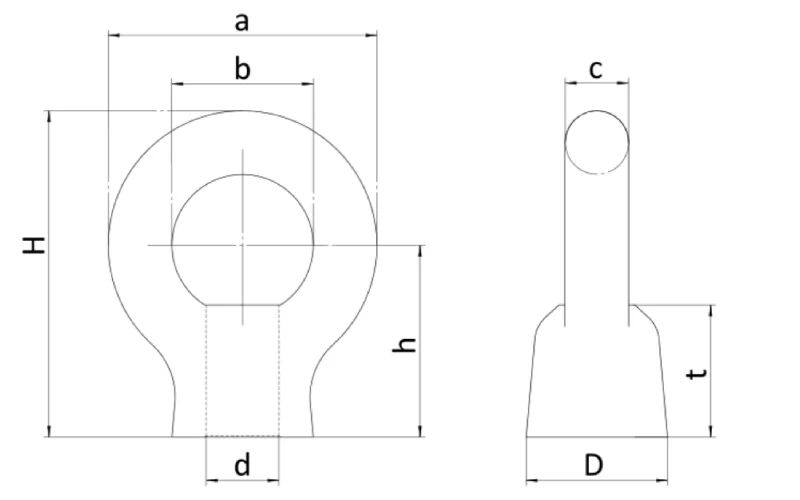

| SIZE | a | b | c | D | t | h | H | SWL | WEIGHT | |

| MM | MM | MM | MM | MM | MM | MM | kg | kN | KG/PC | |

| M6 | 26 | 16 | 5 | 13 | 10 | 19 | 32.5 | 60 | 0.588 | 0.015 |

| M8 | 32.6 | 20 | 6.3 | 16 | 12 | 23 | 39.3 | 80 | 0.785 | 0.03 |

| M10 | 41 | 25 | 8 | 20 | 15 | 28 | 48.5 | 150 | 1.47 | 0.06 |

| M12 | 50 | 30 | 10 | 25 | 19 | 36 | 61 | 220 | 2.16 | 0.125 |

| M14 | 60 | 35 | 12.5 | 30 | 23 | 42 | 72 | 330 | 3.23 | 0.23 |

| M16 | 60 | 35 | 12.5 | 30 | 23 | 42 | 72 | 450 | 4.41 | 0.22 |

| M18 | 72 | 40 | 16 | 35 | 28 | 50 | 86 | 540 | 5.29 | 0.39 |

| M20 | 72 | 40 | 16 | 35 | 28 | 50 | 86 | 630 | 6.18 | 0.38 |

| M22 | 81 | 45 | 18 | 40 | 33 | 58 | 98.5 | 790 | 7.74 | 0.56 |

| M24 | 90 | 50 | 20 | 45 | 38 | 66 | 111 | 950 | 9.32 | 0.8 |

| M27 | 110 | 60 | 25 | 60 | 46 | 80 | 135 | 1200 | 11.7 | 1.62 |

| M30 | 110 | 60 | 25 | 60 | 46 | 80 | 135 | 1500 | 14.7 | 1.58 |

| M33 | 110 | 60 | 25 | 60 | 46 | 80 | 135 | 1900 | 18.6 | 1.51 |

| M36 | 133 | 70 | 31.5 | 70 | 55 | 95 | 161.5 | 2300 | 22.6 | 2.75 |

| M42 | 151 | 80 | 35.5 | 80 | 64 | 109 | 184.5 | 3400 | 33.3 | 4.1 |

| M48 | 170 | 90 | 40 | 90 | 73 | 123 | 208 | 4500 | 44.1 | 5.9 |

| M64 | 210 | 110 | 50 | 110 | 90 | 151 | 256 | 9000 | 88.3 | 10.5 |

Products Diagrams

Each JIS B 1169 Eye Nut features precise threading and calibrated load ratings for secure attachment. The design minimizes stress under heavy loads and guarantees consistent performance in vertical lifting or static securing conditions.

The polished finish provides excellent corrosion resistance, ideal for outdoor and marine environments. The round eye design allows smooth load distribution, ensuring stable lifting with wire ropes or shackles.

Material Specification

Grade:

Manufactured to JIS B 1169 standards, ensuring reliable mechanical strength and tested load capacities for safe lifting performance.

Finish:

Available in hot-dip galvanized or stainless steel finish, offering superior corrosion resistance and extended service life.

Attachment:

Internal threaded connection allows easy installation onto bolts or rods, ensuring secure anchoring for lifting and rigging applications.

JIS B 1169 Type Eye Nut Type:

Standard metric thread type with rounded eye design, compliant with Japanese Industrial Standards for universal lifting uses.

Material:

Forged carbon steel or stainless steel (A2/A4) for enhanced toughness, durability, and weather protection in industrial environments.

Application

Construction Industry

Used for lifting beams, formwork, and heavy equipment safely, ensuring efficiency and reliability in construction sites.

Marine & Offshore

Ideal for rigging and anchoring applications exposed to saltwater environments, providing long-lasting corrosion resistance.

Mining Industry

Applied in lifting, securing, and material handling operations under high-stress conditions in mining and quarrying sites.

Advantages

Corrosion & Finish Protection

Galvanized or stainless finishes protect against rust, extending lifespan in marine or outdoor use.

Customization & Traceability

Offered with custom threads, markings, and full material traceability to meet OEM or project-specific requirements.

Load Control & Durability

Designed to withstand high load pressures and maintain structural integrity under heavy-duty applications.

Bulk Capacity & Lead Time

Strong production capacity with short lead times, ideal for wholesalers and large industrial supply orders.

What Our Clients Say

FAQ

What is a JIS B 1169 Type Eye Nut?

It’s a threaded lifting component designed according to Japanese Industrial Standards (JIS). It’s used to secure loads, lift machinery, or attach rigging systems safely.

What materials are available for your JIS B 1169 Eye Nuts?

We offer both carbon steel and stainless steel variants. Stainless steel provides corrosion resistance for marine use, while carbon steel suits general industrial lifting.

Can I order customized eye nuts with my company logo or specifications?

Yes, Powerful Machinery provides OEM customization including thread size, surface finish, and logo marking to meet your project or brand requirements.

Are your eye nuts tested before shipping?

Every batch undergoes load testing, dimensional checks, and surface inspections to ensure compliance with JIS standards and customer specifications.

What is the recommended use direction for these eye nuts?

They are designed for vertical lifts. For angular lifting, we recommend additional safety accessories or shoulder-type designs.

Do you offer bulk order discounts or fast delivery?

Yes, we provide competitive pricing for large-volume orders and maintain efficient production capacity to ensure timely delivery worldwide.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.