Product Specifications

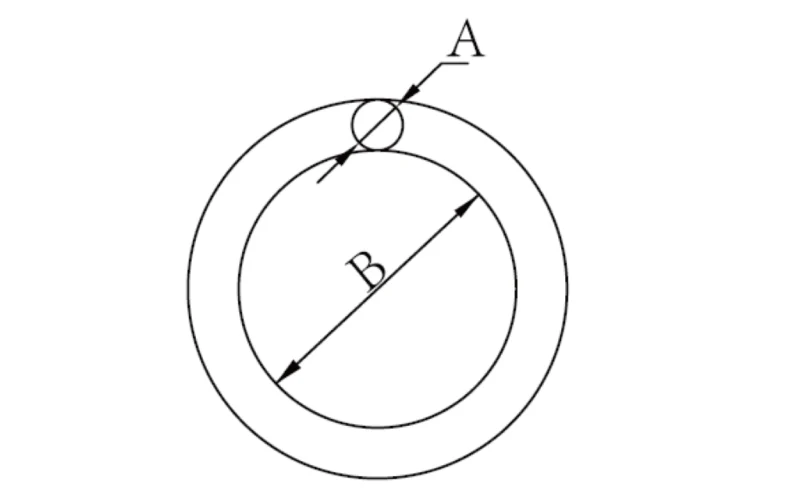

| SIZE | WEIGHT | WIL | BL | A | B |

| IN. | KG/PC | TON | TON | MM | MM |

| 3/8″×2″ | 0.11 | 0.5 | 3 | 10 | 50 |

| 1/2″×2″ | 0.21 | 1 | 6 | 13 | 50 |

| 5/8″×3″ | 0.46 | 1.5 | 9 | 16 | 76 |

| 5/8″×3-5/16″ | 0.5 | 1.5 | 9 | 16 | 84 |

| 3/4″×3″ | 0.67 | 2.3 | 13.8 | 19 | 76 |

| 3/4″×4″ | 0.84 | 2.5 | 15 | 19 | 102 |

| 7/8″×4″ | 1.2 | 3.3 | 19.8 | 22 | 102 |

| 7/8″×5-1/2″ | 1.55 | 2.5 | 15 | 22 | 140 |

| 1″×4″ | 1.59 | 4.9 | 29.4 | 25 | 102 |

| 1″×5-1/2″ | 2.1 | 4.9 | 29.4 | 25 | 140 |

| 1-1/8″×6″ | 2.87 | 4.7 | 28.2 | 28 | 152 |

| 1-1/4″×5″ | 3.1 | 7.7 | 46.2 | 32 | 127 |

| 1-1/4″×6″ | 3.6 | 7.7 | 46.2 | 32 | 152 |

| 1-1/4″×10″ | 5.6 | 7.7 | 46.2 | 32 | 254 |

| 1-3/8″×6″ | 4.5 | 8.6 | 51.6 | 35 | 152 |

| 1-1/2″×8″ | 6.8 | 11.3 | 67.8 | 38 | 203 |

| 1-1/2″×8-3/4″ | 7.32 | 11.3 | 67.8 | 38 | 222 |

| 1-1/2″×10″ | 8.22 | 11.3 | 67.8 | 38 | 254 |

| 1-1/2″×12″ | 17.8 | 15.9 | 95.4 | 38 | 305 |

Products Diagrams

The Drop Forged Weldless Round Ring is a single-piece, seamless forging designed to eliminate weak weld joints. Its continuous circular structure ensures maximum strength and even load distribution, making it perfect for applications requiring high tensile resistance and safety under dynamic loading conditions.

Each round ring is crafted with precise dimensional tolerances, ensuring smooth integration with chains, hooks, and slings. The perfectly symmetrical shape provides balanced tension during lifting operations, reducing stress points and increasing operational safety across various industrial environments.

Material Specification

Grade:

Produced from high-tensile alloy steel, these rings meet international quality standards such as EN and ISO, guaranteeing excellent strength and mechanical performance.

Finish:

Available in hot-dip galvanized, self-colored, or painted finishes to resist corrosion and environmental wear, ensuring long-term use in harsh conditions.

Attachment:

Easily connects with chains, hooks, or wire ropes. The circular design allows flexible load alignment in any direction for safe and efficient lifting.

Drop Forged Weldless Round Rings Type:

Offered in standard, heavy-duty, and custom types. Suitable for general lifting, marine mooring, and mining rigging systems.

Material:

Made from premium-grade carbon steel or alloy steel, providing high tensile strength and superior resistance to deformation or fatigue.

Application

Construction Industry

Used for connecting lifting slings and hoists. These weldless round rings ensure secure load handling during heavy construction and infrastructure operations.

Marine & Offshore

Ideal for ship rigging, anchor connections, and mooring systems. The weldless design offers strong, corrosion-resistant performance in saltwater environments.

Mining Industry

Perfect for hoisting and pulling heavy loads. Designed to withstand extreme impact, vibration, and abrasive mining conditions with long-lasting durability.

Advantages

Corrosion & Finish Protection

Each ring is surface-treated for enhanced corrosion resistance, providing reliable use in outdoor, marine, and chemical-exposed environments.

Customization & Traceability

Custom sizes, markings, and finishes are available. Every batch includes full traceability records, ensuring quality assurance and international compliance.

Load Control & Durability

The seamless forged structure provides uniform stress distribution, high load capacity, and extended operational lifespan under heavy-duty industrial use.

Bulk Capacity & Lead Time

We support large-volume production with consistent quality, quick lead times, and competitive pricing for distributors and OEM manufacturers worldwide.

What Our Clients Say

FAQ

What are Drop Forged Weldless Round Rings used for?

These rings are used for connecting lifting slings, hooks, and chains in construction, mining, and marine environments. Their seamless, weldless design ensures uniform strength and prevents cracking or failure under high tension.

What makes them “weldless”?

“Weldless” means the ring is forged from a single piece of metal without any welded joints. This improves mechanical strength, eliminates weak spots, and enhances reliability in load-bearing applications.

What’s the difference between forged and welded rings?

Forged rings are stronger and more durable than welded ones. The forging process refines the metal’s grain structure, providing uniform density and resistance to deformation under stress.

Can you produce custom sizes or finishes?

Yes. Powerful Machinery supports OEM and ODM customization, offering tailor-made diameters, load ratings, and finishes like galvanization, powder coating, or painting based on your needs.

How do you test product quality?

Each Drop Forged Weldless Round Ring is inspected for hardness, tensile strength, and dimensional accuracy. We perform non-destructive testing to ensure consistent quality and safety compliance.

What are your production and delivery capabilities?

Our advanced forging equipment allows high-volume production with stable quality. Standard items ship within 7–15 days; custom sizes may take up to 25 days depending on quantity.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.