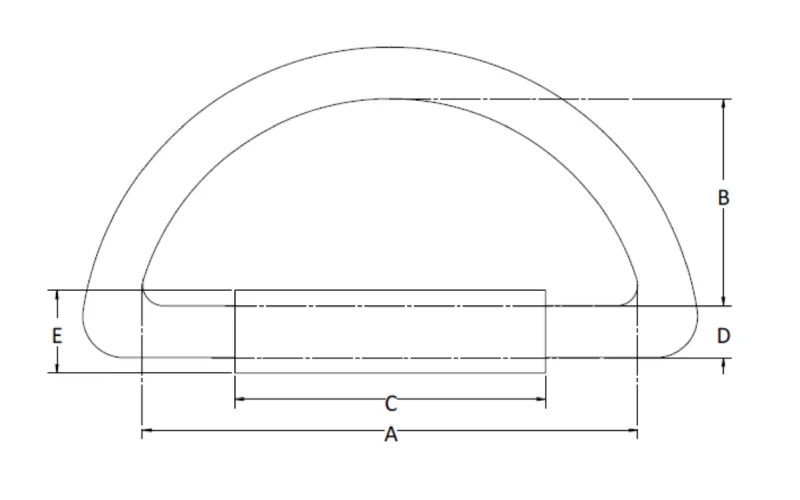

Product Specifications

| SIZE | A | B | C | D | E | WEIGHT | MBS |

| MM | MM | MM | MM | MM | MM | KG/PC | TON |

| 21 | 136 | 80 | 120 | 21 | 25.5 | 2.46 | 36 |

| 25 | 144 | 88 | 125 | 25 | 30 | 3.7 | 41 |

| 27 | 151 | 90 | 130 | 27 | 50 | 4.41 | 50 |

Products Diagrams

The Forged D Ring With Strap features a solid steel D-ring securely attached to a weld-on base plate. Its robust design ensures uniform load distribution, preventing bending or failure during heavy hauling. The wide strap base provides strong surface contact for stable attachment to trailer frames or platforms.

From multiple angles, the D Ring With Strap demonstrates a perfect combination of strength and functionality. The welded strap plate allows quick, secure mounting, while the forged D-ring offers smooth movement for tie-down hooks, chains, or straps—ideal for industrial transport and load-securing systems.

Material Specification

Grade:

Manufactured from high-tensile alloy steel, ensuring maximum strength and impact resistance in demanding load-securing and towing operations.

Finish:

Hot-dip galvanized or powder-coated surface provides excellent protection against rust, corrosion, and outdoor weathering.

Attachment:

Equipped with a weld-on strap base, easily attachable to trailers, trucks, or machinery for fixed anchor points.

Forged D Ring With Strap Type:

Available in standard, heavy-duty, and customized sizes for different load capacities and operational environments.

Material:

Crafted from premium forged carbon steel or alloy steel for superior durability and long-lasting performance.

Application

Construction Industry

Used to secure equipment, scaffolding, and materials during transport. Ensures reliable tie-down strength for construction vehicles and heavy loads.

Marine & Offshore

Ideal for securing containers, nets, or gear on ships and docks. Provides strong anchoring performance in corrosive saltwater conditions.

Mining Industry

Used for anchoring machinery, transport vehicles, and hauling systems. Offers high tensile strength and dependable safety in rough environments.

Advantages

Corrosion & Finish Protection

The galvanized coating prevents rust and corrosion, extending service life even under extreme weather or marine exposure.

Customization & Traceability

Customizable in size, strap length, and finish. Each unit is batch-coded for traceability and quality verification.

Load Control & Durability

Forged structure ensures even load distribution, exceptional strength, and resistance to bending or cracking under high pressure.

Bulk Capacity & Lead Time

Large production capacity supports bulk orders with short lead times and consistent product quality for global distributors and OEM partners.

What Our Clients Say

FAQ

What is a Forged D Ring With Strap used for?

It is used as a secure anchor point on trailers, trucks, and heavy equipment. The welded strap base allows easy installation and provides strong load support for chains, hooks, or straps during cargo transport.

What makes the forged version stronger?

Forging compresses the metal’s grain structure, improving its strength and durability. This ensures higher load-bearing capacity and eliminates weak points compared to cast or welded alternatives.

Can it be customized for specific applications?

Yes. We offer OEM and custom manufacturing for different sizes, finishes, and load ratings. Our engineering team works with you to meet your project’s technical needs.

How is corrosion protection ensured?

Each D-ring with strap is treated with galvanization or powder coating to resist rust and moisture, ensuring long-term performance in outdoor and marine conditions.

What is the typical load capacity?

Load capacity depends on size and material. Standard models range from 2 tons to over 10 tons. Custom options for higher loads are also available.

How fast can you deliver bulk orders?

With large-scale production lines and ready stock for standard sizes, we ship regular orders in 7–15 days. Custom sizes are typically ready within 20–25 days.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.