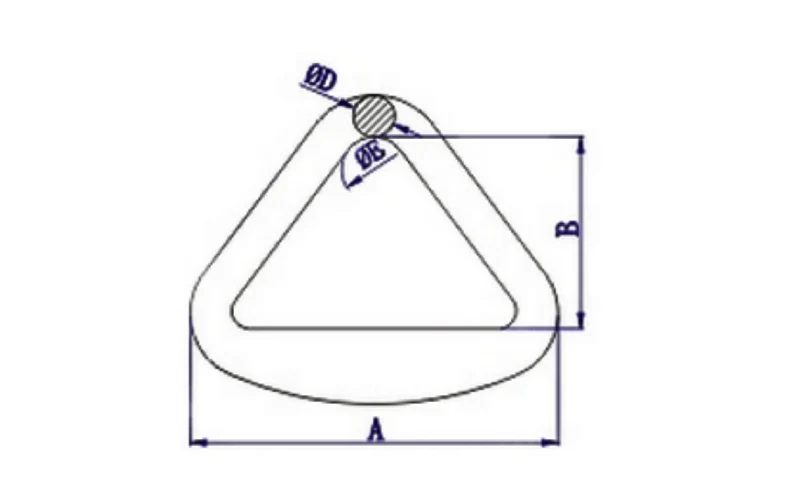

Product Specifications

| SIZE | WEIGHT | B.L | A | B | D | E |

| IN. | KG/PC | TON | MM | MM | MM | MM |

| 2″ | 0.2 | 5 | 80 | 44.5 | 12 | 15 |

| 3″ | 0.36 | 8.2 | 109.4 | 60 | 14 | 20 |

| 4″ | 0.62 | 9.1 | 142 | 74 | 16 | 25 |

Products Diagrams

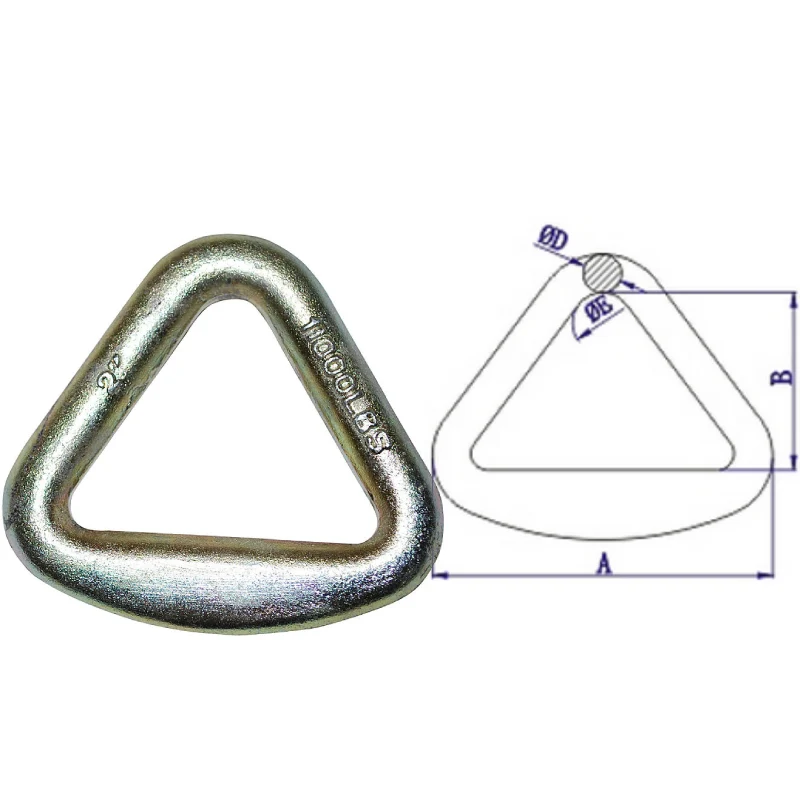

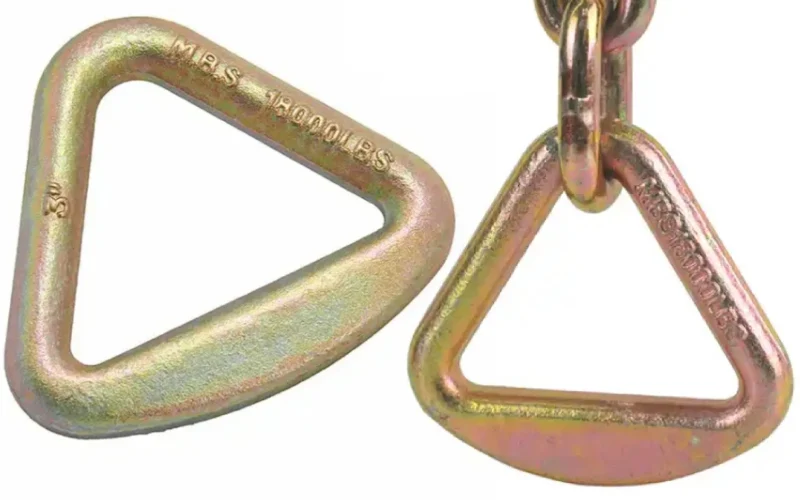

The Forged Delta Ring’s triangular design distributes tension evenly across all sides, minimizing stress concentration. Its forged structure ensures outstanding mechanical strength, preventing deformation during load-bearing operations. This geometry also provides maximum contact area for straps or chains, ensuring reliable performance under tension or vibration.

Viewed from the side and base, the Delta Ring shows its wide opening, suitable for webbing straps and chains. The smooth edges protect the strap surface from abrasion, while the rigid forged body maintains load stability during towing, lifting, or anchoring in construction, marine, or transport systems.

Material Specification

Grade:

Manufactured from high-tensile forged carbon steel, offering exceptional strength, durability, and consistent mechanical performance under dynamic load conditions.

Finish:

Available in white zinc plated, yellow zinc plated, or hot-dip galvanized finishes to provide superior corrosion and rust protection.

Attachment:

Designed to connect seamlessly with webbing straps, tow chains, or lifting hooks for secure and easy assembly.

Forged Delta Ring Type:

Offered in standard and heavy-duty types with various dimensions for load securing, towing, and lifting applications.

Material:

Made from premium-grade forged carbon steel for durability, strength, and resistance to bending or cracking.

Application

Construction Industry

Used for lifting, towing, and load-securing on construction machinery and trailers, ensuring safety and stability during transportation.

Marine & Offshore

Provides reliable anchoring and mooring support for ropes or chains, built to resist corrosion in harsh marine environments.

Mining Industry

Used in haulage and rigging systems to connect heavy-duty straps and chains, offering dependable load control in rugged conditions.

Advantages

Corrosion & Finish Protection

Zinc and galvanized coatings provide long-lasting protection against rust, extending product lifespan in outdoor or marine applications.

Customization & Traceability

Custom sizes, surface treatments, and markings available. Each batch is traceable for quality and safety verification.

Load Control & Durability

Forged design enhances strength and prevents deformation, offering dependable load performance in towing and lifting operations.

Bulk Capacity & Lead Time

High production capability supports large-volume orders with short lead times and stable quality for global distributors and OEM clients.

What Our Clients Say

FAQ

What is a Forged Delta Ring used for?

A Forged Delta Ring is primarily used to connect webbing straps, tow chains, or lifting systems. Its triangular shape provides excellent load stability and evenly distributes force, preventing twisting or wear during transport or lifting.

What makes a forged Delta Ring stronger than a welded one?

Forging compresses the metal’s grain structure, eliminating weak spots and air pockets. This process increases strength, toughness, and fatigue resistance, ensuring the ring performs under extreme loads.

What surface finishes are available?

We provide white zinc plating, yellow zinc plating, and hot-dip galvanization options. Each finish offers varying degrees of rust and corrosion protection depending on your working environment.

Can you customize the Delta Ring size or load capacity?

Yes. Powerful Machinery offers OEM customization, including ring dimensions, coating type, and load rating to meet your exact technical and operational requirements.

What is the working load limit (WLL)?

The Forged Delta Ring’s ultimate load is four times its WLL, ensuring reliable safety margins. WLL varies depending on size, typically ranging from 2T to 10T.

How long does production and delivery take?

For standard models, delivery takes about 7–15 days. Custom or bulk orders may require 20–25 days depending on specifications and order volume.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.