| SIZE | A | B | WEIGHT |

| MM | MM | MM | KG/100PCS |

| 3×25 | 3 | 25 | 0.5 |

| 4×25 | 4 | 25 | 0.91 |

| 4×30 | 4 | 30 | 1.07 |

| 4×40 | 4 | 40 | 1.39 |

| 5×30 | 5 | 30 | 1.73 |

| 5×40 | 5 | 40 | 2.23 |

| 5×50 | 5 | 50 | 2.58 |

| 6×30 | 6 | 30 | 2.72 |

| 6×40 | 6 | 40 | 3.27 |

| 6×50 | 6 | 50 | 3.99 |

| 6×60 | 6 | 60 | 4.69 |

| 7×35 | 7 | 35 | 4.2 |

| 8×40 | 8 | 40 | 6.06 |

| 8×50 | 8 | 50 | 7.32 |

| 10×50 | 10 | 50 | 11.85 |

| 10×70 | 10 | 70 | 15.8 |

Product Specifications

| SIZE | A | C | D | L | SWL | N.W. |

| MM | MM | MM | MM | kgs | LBS | KG/100PCS |

| 5X50 | 25 | 9 | 5 | 50 | 160 | 1.75 |

| 6X60 | 30 | 11 | 6 | 60 | 260 | 2.55 |

| 8X80 | 40 | 13 | 8 | 80 | 400 | 5.7 |

| 10X100 | 50 | 16 | 10 | 100 | 650 | 13.6 |

| 11X120 | 58 | 21 | 11 | 120 | 700 | 18.5 |

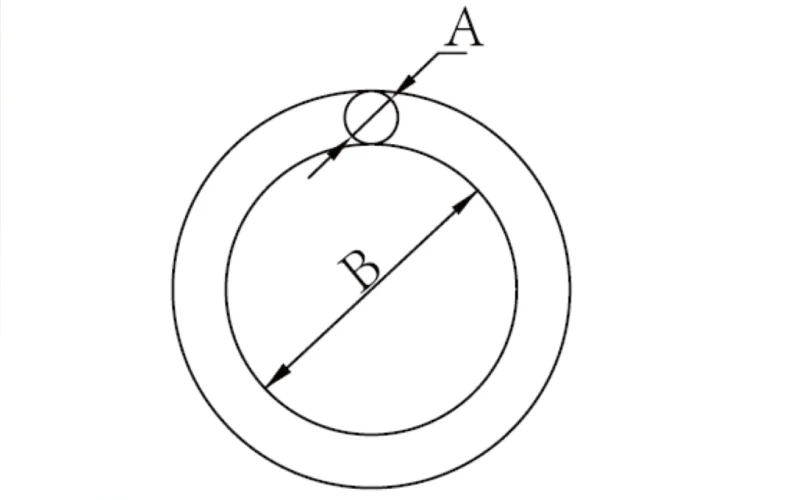

Products Diagrams

Each Welded Round Ring is perfectly circular with a seamless weld joint that ensures even load distribution. Its smooth surface reduces wear and provides a clean, professional finish for heavy-duty applications.

Available in a range of diameters and wire thicknesses, the Welded Round Rings can be customized for specific industrial needs. They maintain excellent shape retention and load capacity under tension.

Material Specification

Grade:

Manufactured from carbon steel or stainless steel grades 304 and 316, ensuring exceptional tensile strength and durability in demanding industrial use.

Finish:

Offered in self-color, electro-galvanized, or hot-dip galvanized coatings for enhanced corrosion resistance and long service life.

Attachment:

Suitable for chain connection, webbing attachment, or rigging setups where secure and reliable linkage is required.

Welded Round Rings Type:

Standard welded circular design with a clean joint to ensure structural integrity and smooth operation under load.

Material:

High-quality carbon or stainless steel, providing both economic and premium-grade options for different working conditions.

Application

Construction Industry

Used for securing scaffolding, lifting tools, and connecting chains during heavy-duty construction operations.

Marine & Offshore

Ideal for mooring, anchoring, and rigging tasks, offering excellent corrosion protection in saltwater environments.

Mining Industry

Applied in lifting and securing equipment within mines, ensuring reliable performance in abrasive, high-stress conditions.

Advantages

Corrosion & Finish Protection

Available in multiple surface finishes, ensuring resistance to rust and environmental damage for extended service life.

Customization & Traceability

Custom diameters, materials, and finishes available with traceable production batches for quality assurance.

Load Control & Durability

Engineered for high load-bearing capacity, providing reliable strength and stability in industrial operations.

Bulk Capacity & Lead Time

Strong production capability ensures consistent quality, fast delivery, and competitive pricing for global bulk buyers.

What Our Clients Say

FAQ

What materials are used in Welded Round Rings?

Our Welded Round Rings are available in carbon steel for general applications and stainless steel (304/316) for corrosion-resistant environments like marine or outdoor industries.

Are the rings tested for strength and safety?

Yes, all our rings undergo strict load and tensile testing to ensure consistent weld strength and safe use in industrial lifting and securing operations.

Can I request custom sizes or finishes?

We provide customized diameters, wire thicknesses, and finishes (zinc, hot-dip galvanized, or polished) to match your project needs.

Do you offer stainless steel Welded Round Rings?

Yes, we offer both 304 and 316 stainless steel grades, ensuring superior corrosion resistance and aesthetic appeal for marine and architectural applications.

How can I place a bulk order?

Simply contact our sales team with your required specifications, quantity, and delivery location. We provide fast quotes and flexible shipping options.

What is the typical production lead time?

Our standard lead time ranges from 20 to 30 days, depending on order volume. We maintain large raw material stocks for fast turnaround.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.