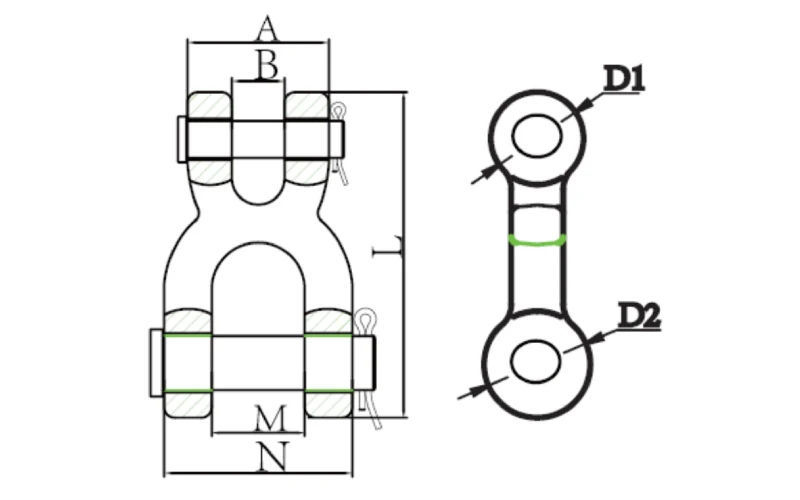

Product Specifications

| SIZE | WEIGHT | WLL | A | B | M | N | L | D1 | D2 |

| IN. | KG/PC | TON | MM | MM | MM | MM | MM | MM | MM |

| 1/4″ | 0.17 | 1.18 | 32 | 13.2 | 19.5 | 37.5 | 72.5 | 20.6 | 25.4 |

| 5/16″-3/8″ | 0.37 | 2.45 | 39.5 | 14.7 | 26 | 52.5 | 90.7 | 25 | 30 |

| 7/16″ | 0.57 | 3.17 | 44 | 18 | 29 | 57.5 | 104 | 30 | 33 |

| 1/2″ | 0.71 | 4.17 | 51 | 21 | 32.3 | 63.5 | 116 | 33 | 37 |

| 5/8″ | 1.3 | 7.94 | 56.8 | 19.8 | 41.4 | 81 | 144 | 41 | 47 |

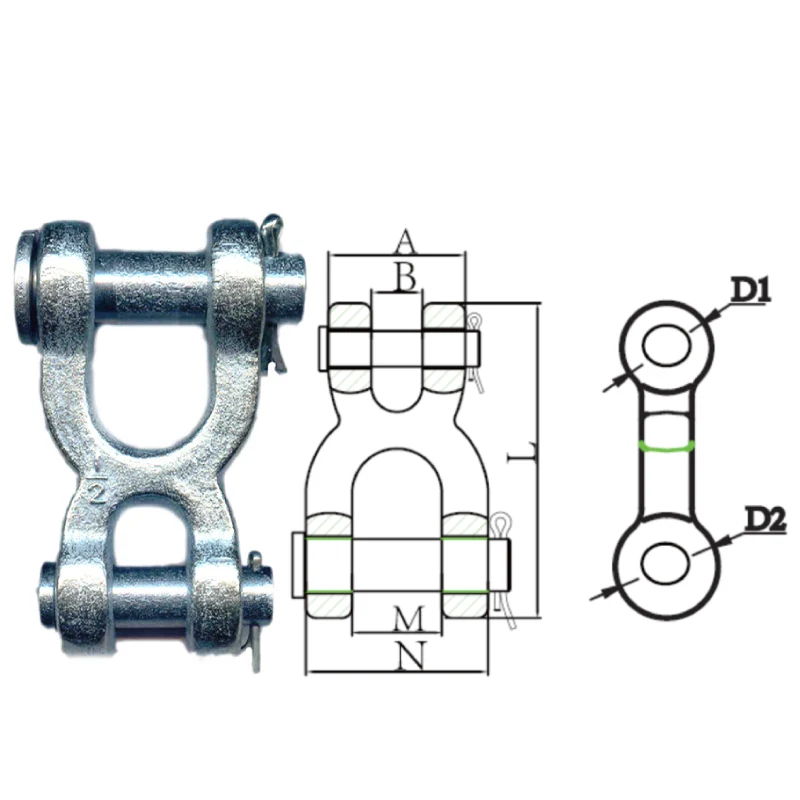

Products Diagrams

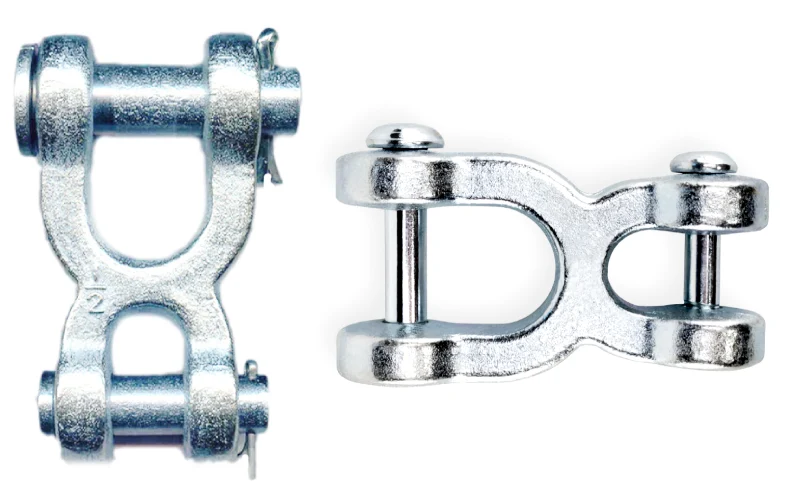

The X Type Double Clevis Link features a twin-clevis structure for even load distribution. The pin connection ensures firm alignment, reducing wear and vibration in dynamic lifting applications.

Its X-shaped geometry allows efficient multi-directional linkage between chains and fittings. This design ensures enhanced flexibility while maintaining superior tensile strength and alignment accuracy.

Material Specification

Grade:

Made from Grade 80 or 100 alloy steel for enhanced tensile strength, meeting industrial and offshore safety standards.

Finish:

Hot-dip galvanized or zinc-plated finish provides long-term rust protection, extending service life even in marine or outdoor conditions.

Attachment:

Equipped with dual clevis ends and a removable pin for quick installation, ensuring secure and stable chain or component connection.

X Type Double Clevis Link Type:

Available in multiple load-rated sizes, suitable for connecting different chain diameters and lifting assemblies.

Material:

Manufactured from high-strength forged alloy steel, tested for impact resistance and deformation control under heavy loads.

Application

Construction Industry

Ideal for cranes, rigging systems, and scaffolding connections where strong, secure, and easy-to-replace links are essential.

Marine & Offshore

Perfect for mooring, towing, and anchor chain connections in saltwater environments, resisting corrosion and fatigue.

Mining Industry

Used in heavy-load transfer, equipment lifting, and conveyor connections, ensuring consistent performance in harsh, dusty environments.

Advantages

Corrosion & Finish Protection

The galvanization and coating process ensures long-lasting protection against rust, reducing maintenance in outdoor and marine settings.

Customization & Traceability

Each link can be laser-marked for batch traceability and customized for specific dimensions or load requirements.

Load Control & Durability

Engineered for balanced load control with high tensile capacity, ensuring safety and extended operational life.

Bulk Capacity & Lead Time

As a direct manufacturer, Powerful Machinery offers bulk supply with fast delivery and stable pricing for global distributors.

What Our Clients Say

FAQ

What is the main function of an X Type Double Clevis Link?

It connects chains, hooks, or eye bolts securely while allowing free movement. Its double-clevis design reduces twisting and ensures even load distribution, improving safety during lifting.

What material is used for your Double Clevis Links?

We use forged alloy steel with high tensile strength. Each link undergoes heat treatment and proof load testing to ensure durability and structural integrity.

Are the X Type Double Clevis Links corrosion-resistant?

Yes. Our links are available with hot-dip galvanization or zinc plating to protect against rust and corrosion in marine or outdoor conditions.

Can I request customized sizes or finishes?

Powerful Machinery provides custom fabrication services, offering specific sizes, finishes, and coatings according to client requirements or industry standards.

Do your links meet international safety standards?

Yes. All X Type Double Clevis Links comply with EN, ASTM, and ISO standards, ensuring safety and quality in lifting, rigging, and marine applications.

. What’s your production and delivery capacity?

We maintain large-scale inventory and can produce thousands of links monthly. Standard orders ship within 15–25 days, with express options for urgent projects.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.