HYDRAULIC STACKER SPECIFICATIONS

| Model | ORM-1000 | ORM-1500/2000 |

| Capacity (kg) | 1000 | 1500/2000 |

| Lifting height (mm) | 1600 | 1600 |

| Lowered fork height (mm) | 100 | 100 |

| Fork length (mm) | 1000 | 800 |

| Fork outside distance (mm) | 745 | 760 |

| Overall dimension (mm) | 1400*780*1850 | 1350*800*1870 |

| Front wheel (mm) | $ 80 | $ 80 |

| Loaded wheel (mm) | $ 180 | $ 180 |

| Net weight (kg) | 120 | 140/180 |

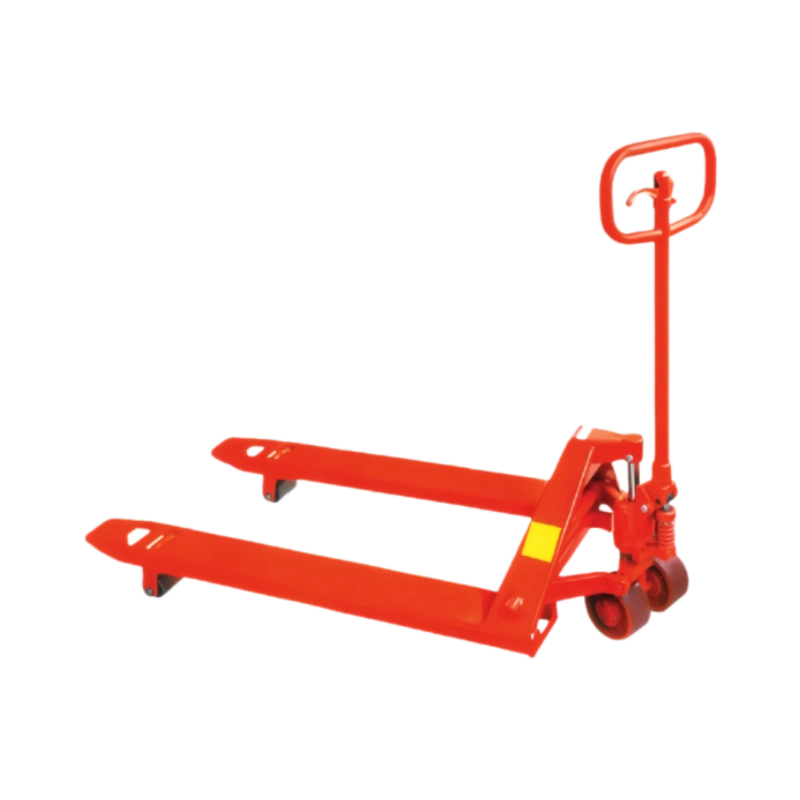

HYDRAULIC STACKER DESIGN

Manual & Power-Free Operation

-

No electricity or fuel required, ensuring an eco-friendly solution for lifting and transportation.

Hydraulic System

-

Operates using hydraulic power, providing smooth lifting and hoisting without the need for an external power source.

Compact & Flexible Design

-

Space-saving structure for easy maneuverability in tight spaces, ideal for use in factories, workshops, and warehouses.

Easy Maintenance

-

Simple design makes it easy to maintain and service, reducing downtime and operational costs.

Versatile Application

-

Perfect for lifting, hoisting, and transporting goods in various industries, including warehouses and distribution centers.

INSTRUCTIONS & CAUTIONS OF HAND HYDRAULIC STACKER

Verify the Weight Capacity

Always check the weight capacity of your hydraulic pallet stacker before use. Exceeding the recommended weight limit can damage the hydraulic system and compromise the stacker’s performance. Stay within the specified weight limits for safe and efficient lifting.

Inspect the Hydraulic System Regularly

Before each use, inspect the hydraulic system for leaks or signs of damage. Make sure the hydraulic fluid is at the correct level. Low fluid levels can result in poor lifting performance and system failure. Regular checks will ensure reliable operation and extend the life of your equipment.

Operate on Level Ground

Always use the hydraulic stacker on stable, level surfaces. Operating on uneven or sloped ground can affect stability and lead to accidents. If you must work on uneven terrain, move with extra caution to avoid tipping or losing control of the stacker.

Store Properly After Use

Once your work is done, store the pallet stacker in a dry, safe location. Lower the forks to the ground and release any pressure from the hydraulic system. Proper storage ensures the stacker remains in good condition, ready for future use.

OUR ADVANTAGES

Customizable to Your Needs

We understand that each business has its own needs. That's why we offer personalized solutions to meet your specific requirements. Whether it’s special configurations or adjustments, we collaborate with you to deliver equipment that perfectly fits your operations. Our tailored approach sets us apart from others in the industry.

Commitment to Quality and Durability

We are proud to manufacture equipment that stands the test of time. Every product undergoes strict quality control checks to ensure it meets industry standards for performance and safety. With Powerful Machinery, you invest in durable, high-quality equipment that helps reduce long-term maintenance and replacement costs.

Outstanding Customer Support

We at Powerful Machinery are committed to providing top-notch customer support. Our team is always ready to assist you, whether you need help with product selection, technical advice, or troubleshooting. We focus on building long-term relationships, ensuring that you receive timely, helpful responses to all your inquiries.

Efficient Delivery and Quick Turnaround

At Powerful Machinery, we recognize the importance of time in your operations. That’s why we ensure fast order processing and reliable delivery to keep your business running smoothly. With our streamlined logistics, you can count on timely product delivery, minimizing any downtime or delays in your workflow.

HYDRAULIC HAND STACKER REVIEWS

FAQ OF HYDRAULIC PALLET STACKER

What are the benefits of using a hydraulic pallet stacker?

Hydraulic pallet stackers are ideal for lifting and transporting heavy loads efficiently, without the need for electricity or fuel. They’re cost-effective, eco-friendly, and easy to maintain. These stackers are compact, making them perfect for tight spaces in warehouses or factories. They’re also highly versatile and reliable, offering a great solution for daily lifting tasks.

How do I choose the right hydraulic pallet stacker for my needs?

-

Determine the Weight Capacity

-

Consider the weight capacity needed for your operation. Ensure the stacker can handle the maximum load you plan to lift without overloading.

-

-

Assess the Required Lift Height

-

Evaluate the lift height necessary for your tasks. This will depend on your shelving or storage system. Choose a model that can comfortably reach the required height.

-

-

Check Fork Dimensions

-

Measure the width and length of the forks to ensure they are compatible with the size of your pallets. This will help prevent mishandling and ensure safe, efficient lifting.

-

-

Evaluate Available Space in Your Facility

-

Consider the size of your work environment. Narrow aisles or large spaces may require different types of stackers. Choose a model that fits your operational layout.

-

-

Consult with Our Expert Team

-

Our team is ready to help you select the perfect hydraulic pallet stacker based on your specific needs. Contact us for personalized recommendations and to ensure optimal efficiency in your operations.

-

What is the recommended maintenance schedule for hydraulic pallet stackers?

Regular maintenance is key to ensuring your hydraulic hand pallet stacker runs smoothly. Check the hydraulic fluid levels, inspect for leaks, and ensure that the forks and wheels are clear of debris. We suggest a thorough check every 6-12 months, but frequent use may require more regular inspections. Maintaining your stacker will reduce downtime and prolong its lifespan.

How long does a hydraulic pallet stacker last?

With proper care and maintenance, hydraulic pallet stackers typically last 5-10 years. The longevity depends on the frequency of use and the maintenance schedule. Regular checks, lubrication, and proper storage will extend the life of your stacker and help avoid costly repairs or replacements down the line.

What weight can a hydraulic pallet stacker handle?

Manual hydraulic stacker come in various capacities, usually ranging from 1,000 kg to 3,000 kg. It’s important to choose a stacker with the right load capacity for your business needs. Our team can help guide you in selecting a model that meets your weight handling requirements, ensuring safe and efficient lifting.

Do you offer training for operating hydraulic pallet stackers?

Yes, we provide comprehensive training for all of our hydraulic pallet stackers. Our training covers the basics of operation, safety, and maintenance. This ensures that your team is well-equipped to handle the stackers safely and efficiently. Proper training reduces the risk of accidents and improves productivity in your operation.

What should I do if my hydraulic pallet stacker needs repairs?

If your hydraulic pallet stacker requires repairs, don’t worry—we’ve got you covered. Simply reach out to our customer support team, and we’ll provide troubleshooting steps or arrange for professional repairs. We also keep a full stock of replacement parts to ensure your stacker is up and running as quickly as possible, minimizing downtime.

Can hydraulic pallet stackers handle different types of pallets?

Yes, hydraulic pallet stackers are designed to handle various pallet types, including standard, euro, and custom-sized pallets. However, it’s important to choose the right fork dimensions for your specific pallet types. Our team can help you find a stacker that’s compatible with your pallets, ensuring smooth and efficient handling.

What are the advantages of hydraulic pallet stackers over electric models?

Hydraulic pallet stackers are more cost-effective than electric models and do not require electricity or batteries, which makes them ideal for environments where power supply is limited. They are also simpler to maintain and operate, offering a straightforward and reliable solution for lifting and moving goods without the complexity or expense of electric alternatives.

How fast can hydraulic pallet stackers lift loads?

Hydraulic pallet stackers typically lift loads at a rate of 5-10 cm per pump stroke, depending on the model. While they may be slower than electric stackers, their manual operation offers precise control, which is essential for accurate lifting and safe transport of goods. For most applications, the lifting speed is sufficient to maintain productivity without rushing.