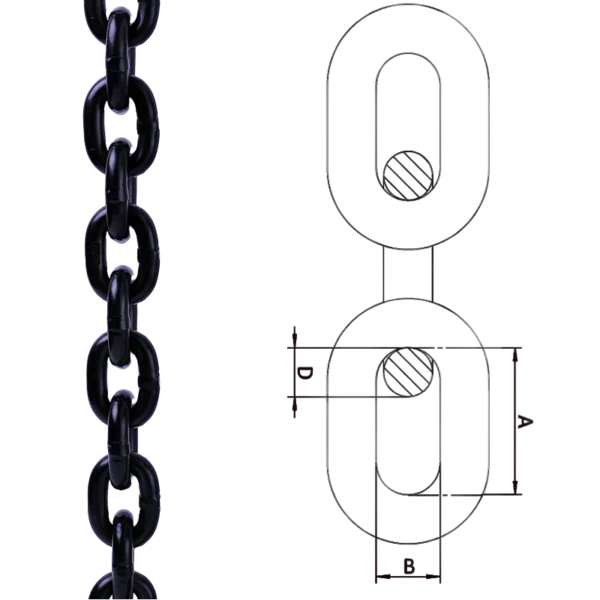

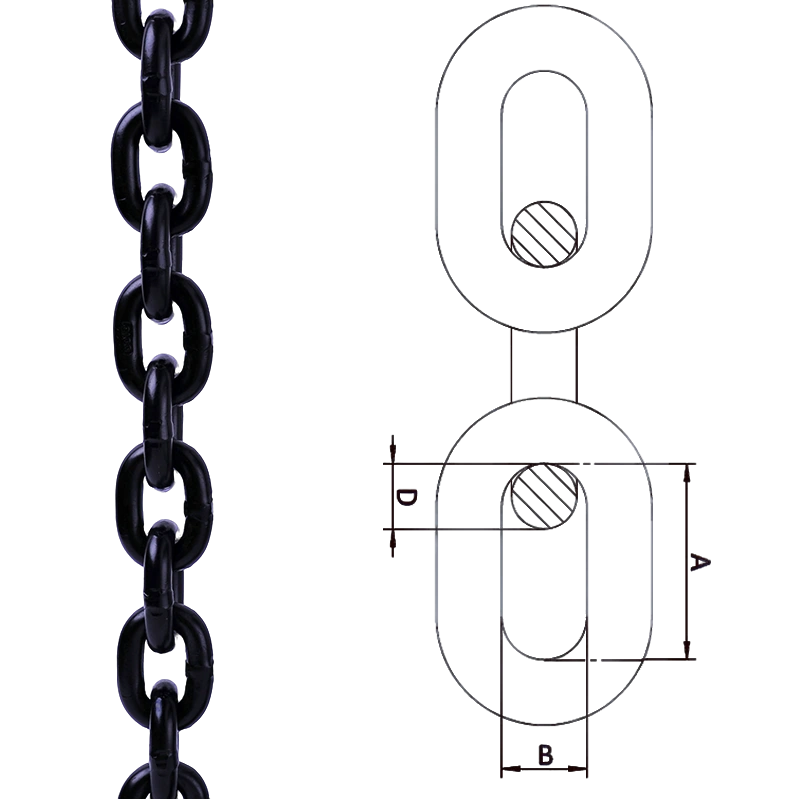

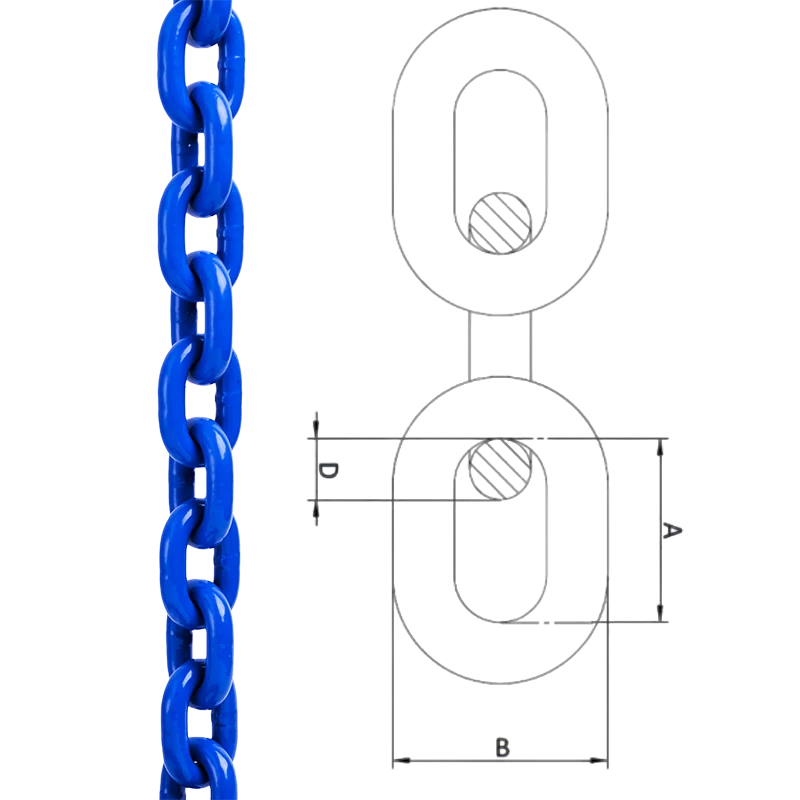

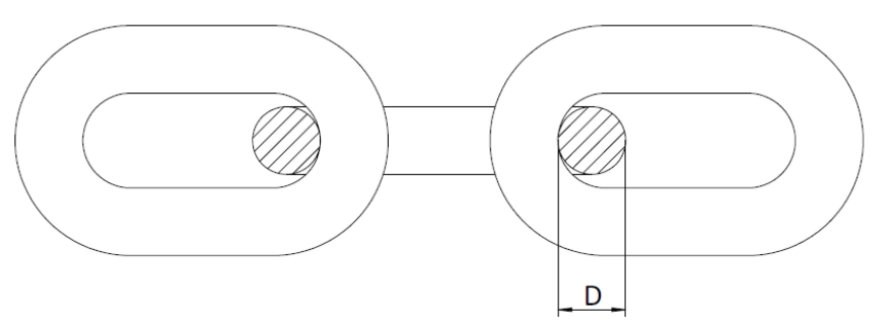

DIAGRAMS

GRADE 80 ALLOY RIGGING CHAIN SPECIFICATIONS

| Nominal Chain Size | Material Diameter | Working Load Limit(Max.) | Proof Test(Min.) | Minimum Breaking Force | Inside Length(Max.) | Inside Width Range | |||||||

| in | mm | in | mm | Ibs | kg | Ibs | kN | Ibs | kN | in | mm | in | mm |

| 7/32 | 5.5 | 0.217 | 5.5 | 2,100 | 970 | 4,200 | 19.0 | 8,400 | 38.0 | 0.69 | 17.6 | 0.281-0.325 | 7.14-8.25 |

| 9/32 | 7.0 | 0.276 | 7.0 | 3,500 | 1,570 | 7,000 | 30.8 | 14,000 | 61.6 | 0.90 | 22.9 | 0.375-0.430 | 9.53-10.92 |

| 5/16 | 8.0 | 0.315 | 8.0 | 4,500 | 2,000 | 9,000 | 40.3 | 18,000 | 80.6 | 1.04 | 26.4 | 0.430-0.500 | 10.92-12.70 |

| 3/8 | 10.0 | 0.394 | 10.0 | 7,100 | 3,200 | 14,200 | 63.0 | 28,400 | 126.0 | 1.26 | 32.0 | 0.512-0.600 | 13.00-15.20 |

| 1/2 | 13.0 | 0.512 | 13.0 | 12,000 | 5,400 | 24,000 | 107.0 | 48,000 | 214.0 | 1.64 | 41.6 | 0.688-0.768 | 17.48-19.50 |

| 5/8 | 16.0 | 0.630 | 16.0 | 18,000 | 8,200 | 36,200 | 161.0 | 72,400 | 322.0 | 2.02 | 51.2 | 0.812-0.945 | 20.63-24.00 |

| 3/4 | 20.0 | 0.787 | 20.0 | 28,300 | 12,800 | 56,600 | 252.0 | 113,200 | 504.0 | 2.52 | 64.0 | 0.984-1.180 | 25.00-30.00 |

| 7/8 | 22.0 | 0.866 | 22.0 | 34,200 | 15,500 | 68,400 | 305.0 | 136,800 | 610.0 | 2.77 | 70.4 | 1.080-1.300 | 27.50-33.00 |

| 1 | 26.0 | 1.020 | 26.0 | 47,700 | 21,600 | 95,400 | 425.0 | 190,800 | 850.0 | 3.28 | 83.2 | 1.280-1.540 | 32.50-39.00 |

| 1-1/4 | 32.0 | 1.260 | 32.0 | 72,300 | 32,800 | 144,600 | 644.0 | 289,200 | 1288.0 | 4.03 | 102.4 | 1.580-1.890 | 40.00-48.00 |

Caution:

DO NOT EXCEED THE WORKING LOAD LIMIT.

WORKING LOAD LIMIT designates the maximum stress in pounds which should ever be applied to chain. This refers also to chain in the best condition, when new, and when the load is applied uniformly to a straight, untwisted length of chain.

WARNING: WORK LOAD LIMIT MUST NOT BE EXCEEDED.

BREAK TEST LOAD is the minimum load in pounds at which new chain has been found by experience to break, under tests in which the load is applied in direct tension to a straight length of chain with a uniform rate of speed on a standard chain testing machine.

DESIGN of Grade 80 Alloy Steel Chain

GRADE

- G80

FINISH

- Self-Color, Polishing, Black, Plastic Coating, Hot-Dip Galvanized. Etc.

STANDARDS

- Meets or exceeds OSHA, Government, NACM, and ASTM specification requirements

HEAT TREATMENT

- Quenched and tempered before proof testing

PRODUCT MARKING

- G80 or required by client.

APPLICATION

- Overhead Lifting/Rigging

MATERIAL

- High-Quality Alloy Steel.

Our Advantages

Flexible Payment

Choose from a range of payment options to suit you such as a 30-day credit account.

Fast Delivery

Enjoy fast delivery with quick processing and timely arrivals for all your orders.

Best Rated

We Are the Highest Rated Lifting Chains Manufacturer in China With 20 Years of Experience & Knowledge

Price Match Guarantee

We are committed to offering the best prices and ensuring you never pay more than necessary.

FAQ of Grade 80 Alloy Chain

What does alloy chain mean?

Alloy chain means a lifting chain made from alloy steel that combines carbon steel with added elements like chromium and molybdenum. These elements increase strength, toughness, and resistance to fatigue under load. You use alloy chain when lifting demands precision, repeatability, and safety. As a manufacturer, alloy composition control defines working load limits and service life. You gain predictable performance because alloy chain responds consistently to stress, bending, and shock loading during real lifting operations.

What is G80 alloy chain?

G80 alloy chain refers to Grade 80 lifting chain designed for overhead lifting. Grade 80 means the chain meets specific strength and performance requirements used in cranes and hoists. You choose G80 alloy chain because it balances strength, flexibility, and durability. Manufacturing control over heat treatment and proof testing ensures each link handles working load repeatedly without deformation.

What is the maximum temperature for most alloy steel chain?

Most alloy steel chain performs safely up to around 400°C during short exposure. You reduce working load limits as temperature rises to protect chain structure. Excess heat changes steel properties and shortens service life. As a manufacturer, temperature ratings guide safe use in high-heat environments like steel plants or energy facilities. You must always match temperature exposure with load reduction planning.

Temperature use guidance

-

Full rated load below 200°C

-

Reduced load above 200°C

-

Limited exposure near 400°C

-

No lifting after overheating

-

Visual inspection after heat use

Which industries use alloy sling chain?

Alloy sling chain supports industries that demand controlled lifting and repeatable performance. You see alloy chain in environments where failure risks equipment and lives. Manufacturing precision ensures chain consistency across batches so industrial buyers standardize lifting systems.

Industries relying on alloy chain

-

Construction and infrastructure

-

Oil and energy facilities

-

Shipbuilding and marine repair

-

Mining and quarry operations

-

Heavy manufacturing plants

-

Port and logistics terminals

Does alloy chain rust?

Alloy chain can rust because alloy steel contains iron. Rust forms when moisture and oxygen contact the surface. You control corrosion through coatings, lubrication, and storage practices. As a manufacturer, surface treatment options help slow corrosion during service. You must manage rust because corrosion reduces cross-section strength over time.

Ways to manage corrosion

-

Dry storage

-

Regular lubrication

-

Surface coatings

-

Routine inspection

-

Early replacement planning

How does G80 alloy chain compare to lower-grade chain?

G80 alloy chain delivers higher strength and better fatigue resistance than lower-grade carbon chains. You lift heavier loads with smaller chain sizes. Manufacturing-grade control ensures predictable elongation and break behavior. Lower grades suit load binding rather than overhead lifting.

Comparison highlights

-

Higher working load limit

-

Better shock resistance

-

Designed for overhead lifting

-

Longer service life

-

Compatible with lifting fittings

How should G80 alloy chain be inspected?

Inspection keeps lifting operations safe. You inspect alloy chain before use and during service life. Visual checks catch wear, stretching, or cracks early. Manufacturer markings help confirm grade and size during inspections.

Inspection focus areas

-

Link elongation

-

Surface cracks

-

Excessive wear

-

Heat discoloration

-

Missing identification marks

Why does heat treatment matter in alloy chain manufacturing?

Heat treatment defines chain strength and flexibility. Controlled heating and cooling align steel grain structure for lifting use. You benefit from consistent performance because heat treatment stabilizes load behavior across every link. Manufacturers control this process to prevent brittle failure.

Heat treatment benefits

-

Balanced hardness

-

Improved fatigue life

-

Stable load response

-

Reduced crack risk

-

Reliable proof testing