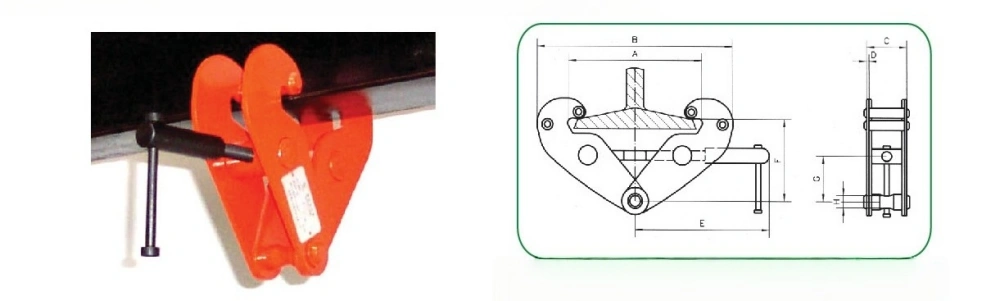

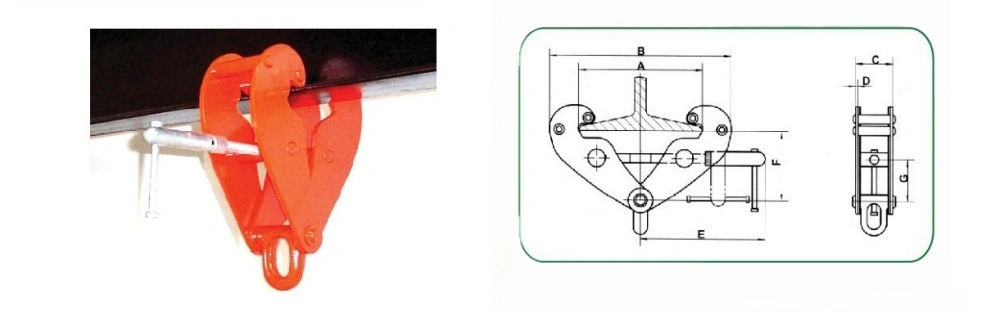

BEAM CLAMP DRAWING

MODEL: TBC BEAM CLAMP

MODEL: TBE BEAM CLAMP

BEAM CLAMP SPECIFICATIONS

TBE BEAM CLAMP SPECIFICATIONS

| Model | 1T | 2T | 3T | 5T | 10T | |

| Capacity(kg) | 1000 | 2000 | 3000 | 5000 | 10000 | |

| Running test load(kN) | 14.71 | 29.40 | 44.13 | 61.29 | 122.58 | |

| Adjustable Beam Width(MM) | 75~230 | 75~230 | 80~320 | 90~320 | 90~320 | |

| Dimensions(mm) | Amax | 278 | 278 | 356 | 356 | 356 |

| Bmax | 380 | 380 | 500 | 500 | 500 | |

| Bmin | 183 | 183 | 220 | 220 | 250 | |

| C | 64 | 76 | 100 | 112 | 120 | |

| D | 4 | 6 | 8 | 10 | 12 | |

| E | 217 | 217 | 277 | 277 | 285 | |

| Fmax | 150 | 150 | 220 | 220 | 230 | |

| Fmin | 90 | 90 | 145 | 145 | 160 | |

| G | 26 | 26 | 50 | 47 | 52 | |

| Net weight(kg) | 3.5 | 4.5 | 9.5 | 11 | 16 | |

TBC BEAM CLAMP SPECIFICATIONS

| Model | 1T | 2T | 3T | 5T | 10T |

| Capacity(kg) | 1000 | 2000 | 3000 | 5000 | 10000 |

| Running test load(kN) | 14.71 | 29.42 | 44.13 | 61.29 | 122.58 |

| Adjustable Beam Width(MM) | 75~230 | 75~230 | 80~320 | 90~320 | 90~320 |

| Dimensions(mm) | Amax | 278 | 278 | 356 | 356 |

| Bmax | 380 | 380 | 500 | 500 | |

| Bmin | 183 | 183 | 220 | 220 | |

| C | 64 | 76 | 100 | 112 | |

| D | 4 | 6 | 8 | 10 | |

| E | 217 | 217 | 277 | 277 | |

| Fmax | 150 | 150 | 220 | 220 | |

| Fmin | 90 | 90 | 145 | 145 | |

| G | 26 | 26 | 50 | 47 | |

| H | 10 | 11 | 22 | 22 | |

| Net weight(kg) | 3.5 | 4.5 | 9.5 | 11 | 16 |

BEAM CLAMPS INFORMATION

Capacity Range

Available in a variety of sizes, from 2 to 10 metric tons, making it ideal for different lifting demands

Durable Construction

Built with a welded alloy steel body for enhanced strength and compact size. Forged alloy components are used where required, ensuring durability and reliability.

Safety & Certification

Each beam clamp is proof-tested to 2x its working load limit and comes with a test certificate. Every unit is individually serialized, with serial numbers and test dates marked on the body, ensuring traceability and safety compliance.

Tracking & Customization

Equipped with RFID technology, which allows easy tracking and maintenance. We also offer customization options, including shackles and reinforced jaw designs, to suit your specific lifting needs.

Maintenance & Support

ISO9001-certified maintenance facilities and readily available replacement parts ensure your equipment remains in optimal condition for long-term use.

Applications

Perfect for transferring steel beams and attaching tackle eyes in heavy-duty lifting operations, particularly in construction and industrial settings.

Additional Features

Available with shackles and features a special design with flattened, reinforced jaws, ensuring a secure and reliable connection for heavy-duty lifting.

INSTRUCTIONS & CAUTIONS

Inspect Before Use

Always check the beam clamp for any signs of wear, cracks, or damage before each use. If you spot any issues, don’t use the clamp. Ensuring the clamp is in top condition is crucial for safety. Damaged or worn equipment can lead to accidents, so regular inspections are a must for safe operations.

Verify the Weight Capacity

Make sure the Working Load Limit (WLL) of your beam clamp matches the weight of the load you’re lifting. Overloading can cause the clamp to fail, putting both the load and workers at risk. Always double-check that the load doesn’t exceed the rated capacity to ensure safe lifting.

Secure Properly

The beam clamp must be firmly attached to both the beam and lifting equipment. Loose or improperly secured clamps can slip or shift during the lift, leading to dangerous situations. Double-check connections and ensure everything is tight and secure before lifting.

Maintain and Replace Regularly

Keep up with regular maintenance and inspections. If you use your clamp frequently or in harsh conditions, check it regularly for wear and replace any parts as needed. Using only genuine replacement parts helps ensure your clamp stays reliable and functional over time, preventing costly downtime.

OUR ADVANTAGES

Custom Solutions to Fit Your Needs

Every project is different. That’s why we provide custom-engineered solutions to fit your specific requirements. Our team works with you to design and deliver equipment that meets your exact needs, improving efficiency and ensuring the success of your operations.

Comprehensive One-Stop Sourcing

Streamline your procurement with our one-stop sourcing solution. We offer a wide range of lifting equipment tailored to your needs, ensuring that no matter the scale of your project, you’ll find exactly what you need without the hassle of dealing with multiple suppliers.

Trustworthy Quality and Safety

We prioritize quality and safety in all our products. Each item is rigorously tested to meet high industry standards, ensuring reliable performance and minimizing risk. Partner with us for lifting equipment that you can trust to get the job done safely and efficiently.

Top-Notch Customer Service

We take customer service seriously. From product selection to after-sales support, our team is dedicated to helping you every step of the way. Get the answers and support you need, when you need them, to keep your operations running smoothly.

FAQ

What is a Beam Clamp?

A beam clamp is a versatile piece of lifting equipment designed to secure steel beams or other heavy loads for lifting, hoisting, or rigging operations. It attaches directly to beams, creating a stable connection point for lifting slings, hooks, or other rigging devices. Ideal for both temporary and permanent lifting applications, beam clamps offer excellent safety and efficiency.

What Are the Different Types of Beam Clamps?

There are several types of beam clamps, including adjustable, fixed, and self-locking clamps. Adjustable beam clamps allow flexibility to fit various beam sizes, while fixed clamps are more robust for permanent applications. Self-locking clamps automatically secure themselves on the beam, ensuring easy setup without additional tools or hardware.

What Are Beam Clamps Used For?

Beam clamps are primarily used in construction and industrial settings to secure beams and provide a stable lifting point. They’re often used for lifting heavy equipment, securing rigging, or temporarily attaching lifting points. Beam clamps are ideal for applications requiring quick, reliable setups, especially in tight spaces or areas where traditional lifting methods aren’t practical.

How Are Beam Clamps Intended to Be Used?

Beam clamps are designed to be installed onto steel beams or similar structural supports. To use a beam clamp, position it on the beam, ensuring it’s securely fastened. Once attached, the clamp creates a stable point for lifting slings or hoists. Always ensure the clamp is installed correctly before applying any load. Follow safety guidelines and manufacturer instructions for proper installation.

How Much Weight Can a Beam Clamp Hold?

The weight capacity of a beam clamp depends on its Working Load Limit (WLL), which can range from a few hundred kilograms to several tons, depending on the clamp’s design. It’s crucial to select a beam clamp with a WLL that matches or exceeds the weight of the load you’re lifting. Always refer to the manufacturer’s specifications to ensure safe lifting.

How Do I Install a Beam Clamp?

-

Position the Clamp: Start by positioning the beam clamp securely on the steel beam. Ensure it is aligned correctly to fit the beam’s dimensions.

-

Tighten the Clamp: Use the adjustment screws or locking mechanism to tighten the clamp, ensuring it’s securely attached to the beam.

-

Attach the Lifting Sling: After securing the clamp, attach your lifting sling or rigging device to the clamp’s designated lifting point.

-

Check for Security: Always double-check that the clamp is securely fastened before beginning the lift to ensure safe operation.

What Is a Beam Clamp Inspection Checklist?

Regular inspections of beam clamps ensure safety and performance. A basic inspection checklist should include checking for:

-

Signs of wear or damage

-

Corrosion or rust

-

Proper function of locking mechanisms

-

Visible cracks or deformations

-

Label and serial number verification for compliance

Always replace any beam clamp that shows signs of damage or exceeds recommended usage.