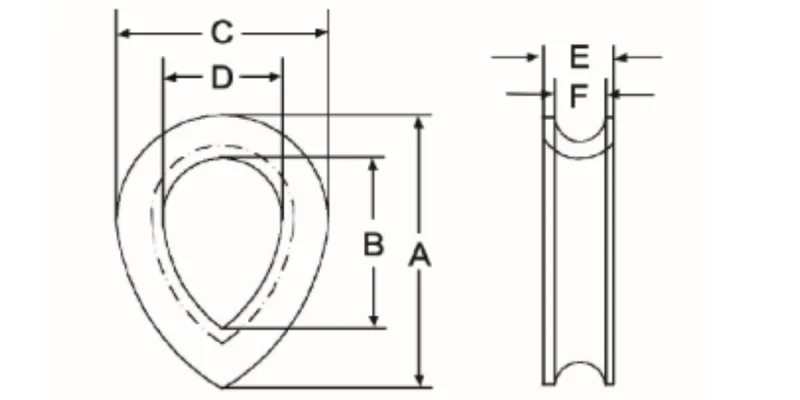

Product Specifications

| BRITISH STANDARD BS464 WIRE ROPE THIMBLE | |||||||

| SIZE | DIMENSION(IN.) | WEIGHT | |||||

| IN. | A | B | C | D | E | F | KG/PC |

| 5/16″ | 2-1/8″ | 1-5/16″ | 1-1/2″ | 7/8″ | 1/2″ | 5/16″ | 0.065 |

| 3/8″ | 2-1/2″ | 1-1/2″ | 1-7/8″ | 1″ | 9/16″ | 13/32″ | 0.091 |

| 7/16″ | 2-7/8″ | 1-1/2″ | 2-1/8″ | 1-1/8″ | 11/16″ | 1/2″ | 0.12 |

| 1/2″ | 3-1/8″ | 1-3/4″ | 2=5/16″ | 1-1/4″ | 13/16″ | 9/16″ | 0.16 |

| 9/16″ | 3-1/8″ | 1-3/4″ | 2-5/16″ | 1-1/4″ | 13/16″ | 9/16″ | 0.172 |

| 5/8″ | 3-7/8″ | 2-5/16″ | 2-15/16″ | 1-5/8″ | 7/8″ | 5/8″ | 0.26 |

| 11/16″ | 4-1/4″ | 2-5/8″ | 3-1/8″ | 1-3/4″ | 1-1/8″ | 3/4″ | 0.34 |

| 3/4″ | 4-7/8″ | 2-7/8″ | 3-5/8″ | 2″ | 1-1/8″ | 13/16″ | 0.45 |

| 7/8″ | 4-1/4″ | 3-1/4″ | 4″ | 2=1/4″ | 1-1/4″ | 7/8″ | 0.62 |

| 15/16″ | 5-3/4″ | 3-5/8″ | 4-11/16″ | 2-1/2″ | 1-5/16″ | 1″ | 0.8 |

| 1″ | 6-3/8″ | 4-1/4″ | 4-11/16″ | 2-3/4″ | 1-3/8″ | 1-1/16″ | 0.95 |

| 1 1/8″ | 7″ | 4-3/8″ | 5-1/4″ | 3″ | 1-1/8″ | 1-1/8″ | 1.27 |

| 1 1/4″ | 7-3/4″ | 5-1/4″ | 6″ | 3-3/4″ | 1-5/8″ | 1-5/16″ | 1.6 |

| 1 3/8″ | 9″ | 6″ | 6-7/8″ | 4-1/8″ | 1-7/8″ | 1-1/2″ | 2.35 |

| 1 1/2″ | 10″ | 6-1/2″ | 7-3/4″ | 4-1/2″ | 2-1/8″ | 1-5/8″ | 3.3 |

| 1 5/8″ | 10″ | 6-1/2″ | 7-3/4″ | 4-1/2″ | 2-3/16″ | 1-3/4″ | 3.35 |

| 1 3/4″ | 11-1/4″ | 7″ | 9″ | 5″ | 2-1/4″ | 2″ | 6.25 |

| 1 7/8″ | 12-1/4″ | 7-1/2″ | 9-3/4″ | 5-1/4″ | 2-5/8″ | 2-1/8″ | 7.7 |

| 2″ | 13″ | 8″ | 10-1/8″ | 5-1/2″ | 2-3/4″ | 2-3/8″ | 8.05 |

| 2 1/8″ | 13″ | 8″ | 10-1/8″ | 5-1/2″ | 2-3/4″ | 2-1/2″ | 8.3 |

| 2 1/4″ | 14″ | 8-1/2″ | 10-5/8″ | 5-3/4″ | 3″ | 2-5/8″ | 8.6 |

| 2 1/2″ | 16-1/4″ | 9-1/2″ | 12-1/4″ | 6-1/4″ | 3-3/4″ | 2-3/4″ | 17 |

Products Diagrams

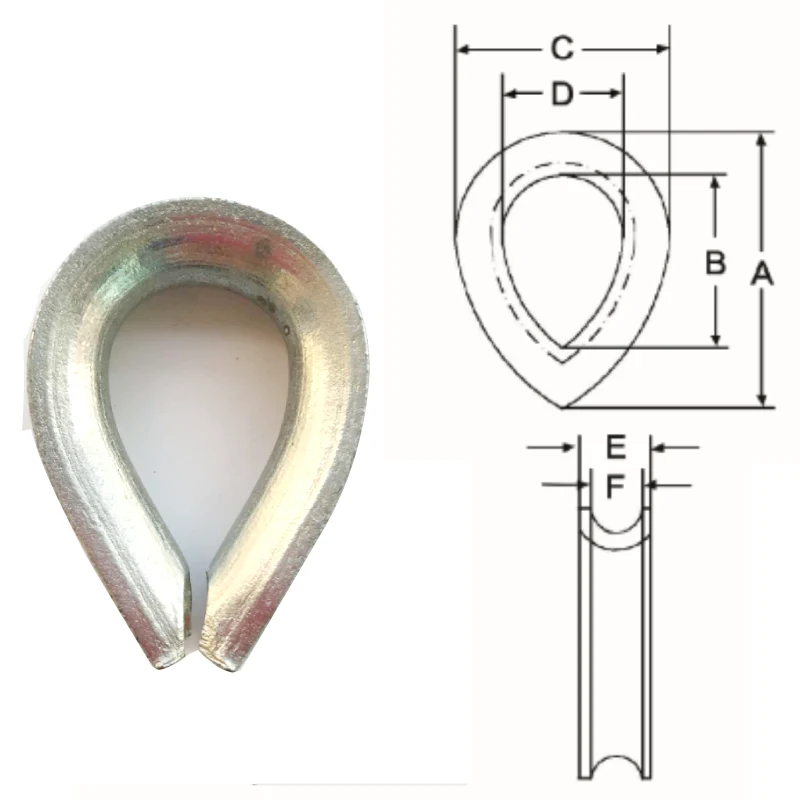

The British Standard BS464 Wire Rope Thimble features a precisely contoured groove that holds the rope securely, preventing crushing or deformation. It maintains the natural loop shape during splicing and ensures even load distribution, offering maximum protection against wear and friction in wire rope assemblies.

This BS464 thimble is designed to meet strict British standards, providing consistent performance under high-tension loads. The smooth inner surface minimizes rope abrasion, while the thick sidewalls and precision forging guarantee long service life in both static and dynamic load applications.

Grade:

Manufactured from high-tensile steel with excellent mechanical properties, suitable for demanding industrial lifting, anchoring, and rigging operations.

Finish:

Available in hot-dip galvanized or polished stainless steel finish, ensuring enhanced corrosion resistance and durability in harsh outdoor conditions.

Attachment:

Installed within a spliced eye to protect the wire rope strands from bending and wear, maintaining loop integrity and safety.

Type:

Built in accordance with BS464 standard dimensions, ensuring compatibility with standard rope sizes and consistent performance.

Material:

Crafted from forged carbon steel or stainless steel, combining superior strength, ductility, and corrosion resistance for extended service life.

Application

Construction Industry

Used for crane cables, hoisting systems, and scaffolding connections, ensuring secure wire terminations and reliable lifting in heavy-duty construction environments.

Marine & Offshore

Provides dependable performance in ship rigging, mooring, and offshore lifting, resisting saltwater corrosion and ensuring long-term operational safety.

Mining Industry

Applied in winch lines, conveyor systems, and safety cables, ensuring high wear resistance and reliable performance in tough mining conditions.

Advantages

Corrosion & Finish Protection

Galvanized and stainless finishes offer superior corrosion resistance, ensuring long-lasting protection in marine and industrial applications with high humidity and exposure.

Customization & Traceability

Available with OEM customization, logo marking, and full traceability documentation, ensuring quality assurance and compliance for industrial buyers.

Load Control & Durability

BS464 standard ensures uniform load distribution and enhanced durability, minimizing wear and extending service life under heavy or repeated stress.

Bulk Capacity & Lead Time

Strong manufacturing capacity supports bulk orders with stable quality, competitive pricing, and fast delivery to meet global industrial supply demands.

What Our Clients Say

FAQ

What is a British Standard BS464 Wire Rope Thimble used for?

A BS464 Wire Rope Thimble is used to reinforce the eye or loop at the end of a wire rope. It protects the rope from friction and deformation when attached to hooks, shackles, or anchors, extending the rope’s lifespan in lifting and rigging systems.

What makes BS464 thimbles different from other standards?

BS464 thimbles follow strict British dimensional and strength requirements, ensuring precise fit and high load-bearing capacity. They are thicker and more durable than generic types, ideal for professional and industrial use.

Are these thimbles suitable for marine use?

Yes. The galvanized and stainless-steel finishes make BS464 thimbles highly resistant to saltwater and humidity, ideal for ship rigging, mooring, and offshore lifting.

Can I order custom sizes or materials?

Yes. Powerful Machinery provides full OEM customization, including special materials, coatings, and dimensions to fit unique project or branding requirements.

How should I install a BS464 Wire Rope Thimble?

Insert the thimble into the spliced eye of the wire rope, ensuring it fits snugly. Secure with wire rope grips or ferrules for a firm and safe connection.

What is your production lead time for bulk orders?

Standard sizes are ready to ship within 10–15 working days. Custom specifications may take slightly longer, depending on order quantity and finish requirements.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.