Product Specifications

| SIZE | b | d | e | f | g | h | SWL |

| IN. | MM | MM | MM | MM | MM | MM | TON |

| 3/8″ | 21 | 7 | 14 | 9 | 19 | 17 | 0.25 |

| 1/2″ | 28 | 10 | 19 | 11 | 25 | 22 | 0.5 |

| 5/8″ | 36 | 12 | 24 | 14 | 32 | 28 | 0.9 |

| 3/4″ | 43 | 14 | 28 | 17 | 38 | 33 | 1.4 |

| 7/8″ | 50 | 17 | 33 | 20 | 44 | 39 | 2 |

| 1″ | 57 | 19 | 38 | 22 | 51 | 44 | 2.75 |

| 1-1/8″ | 64 | 21 | 42 | 25 | 57 | 50 | 3.5 |

| 1-1/4″ | 71 | 24 | 48 | 28 | 64 | 55 | 4.5 |

| 1-1/2″ | 85 | 28 | 57 | 33 | 76 | 67 | 6.5 |

| 1-3/4″ | 101 | 33 | 67 | 39 | 89 | 77 | 9 |

| 2″ | 115 | 38 | 76 | 44 | 102 | 89 | 12 |

| 2-1/4″ | 128 | 42 | 85 | 50 | 115 | 101 | 15 |

| 2-1/2″ | 143 | 48 | 95 | 55 | 127 | 111 | 20 |

| 3″ | 172 | 57 | 115 | 67 | 152 | 133 | 30 |

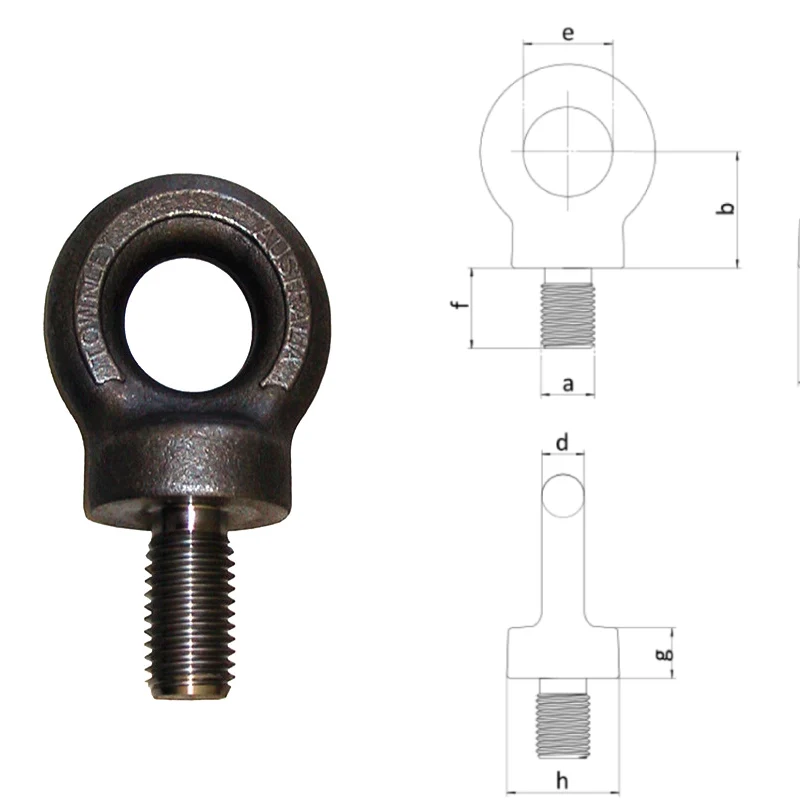

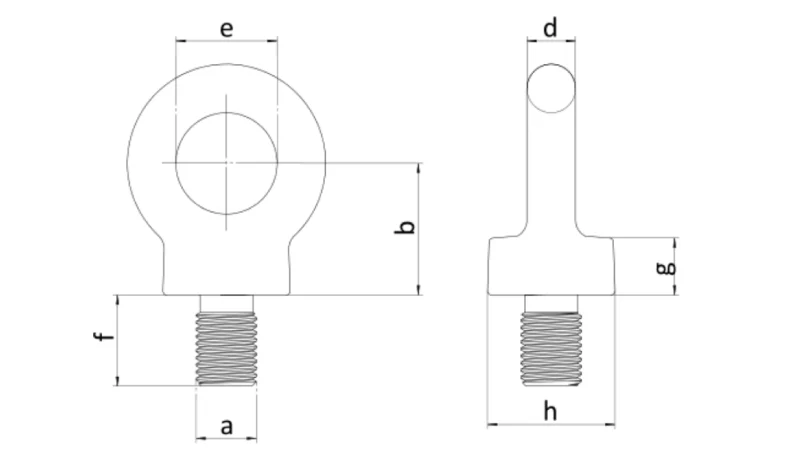

Products Diagrams

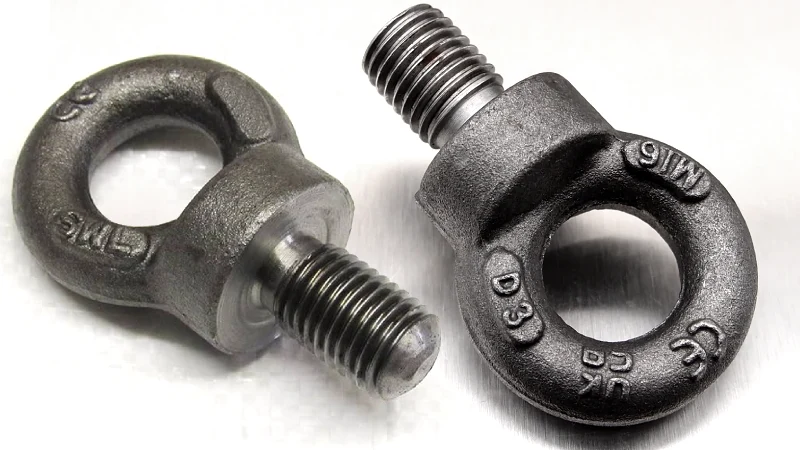

The Bs529 Collared Eye Bolt features a precision-machined eye with a flat collar base for stable load distribution. The threaded shank ensures firm attachment to machinery or anchor points, providing reliable load-bearing strength.

Every bolt is manufactured to meet BS529 standards for dimensional accuracy. The smooth collar design allows even stress transfer during lifting, minimizing wear and extending service life under repeated operations.

Material Specification

| Property | Description |

|---|---|

| Grade: | High-tensile carbon steel or stainless steel, designed for superior strength and fatigue resistance. |

| Finish: | Hot-dip galvanized, zinc-plated, or polished stainless finish for corrosion protection. |

| Attachment: | Threaded shank ensures secure fixing in tapped holes or with corresponding nuts. |

| Bs529 Collared Eye Bolt Type: | Available in Metric and UNC threads; collared type for vertical and angular loading. |

| Material: | Forged steel for durability and safety in heavy-duty lifting and anchoring operations. |

Application

Construction Industry

Used to lift and secure structural components, prefabricated panels, and heavy machinery safely on construction sites.

Marine & Offshore

Ideal for hoisting and securing ship parts, anchors, or equipment in saltwater environments. Corrosion-resistant and dependable.

Mining Industry

Used for lifting mining equipment, pumps, and assemblies under tough working conditions requiring high load safety.

Corrosion & Finish Protection

Protective coating resists rust and oxidation, extending service life even in humid or coastal environments.

Customization & Traceability

Full OEM customization with traceable production records for compliance and quality assurance.

Load Control & Durability

Engineered for uniform stress distribution, ensuring long-term stability under continuous or angled loads.

Bulk Capacity & Lead Time

Large manufacturing capacity guarantees quick delivery and stable supply for bulk and project-based orders.

What Our Clients Say

FAQ

What is a Bs529 Collared Eye Bolt used for?

A Bs529 Collared Eye Bolt is used as a lifting or anchor point for attaching chains, slings, or ropes. Its collared design provides stability for vertical or angled loads.

What materials do you offer?

We supply eye bolts in carbon steel and stainless steel. Both options deliver high strength, while stainless steel provides superior corrosion resistance for marine and outdoor applications.

Can I order customized sizes or threads?

Yes. We manufacture eye bolts to your required size, thread type, and coating. Custom branding and packaging for OEM orders are also available.

Are Bs529 Collared Eye Bolts tested for safety?

Each batch undergoes tensile load testing, thread inspection, and surface finishing checks before dispatch to ensure consistent performance and safety compliance.

What’s the difference between collared and plain eye bolts?

Collared eye bolts distribute load stress more evenly, making them suitable for angular lifting, while plain types are better for straight vertical loads.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.