CABLE PULL GRIP SPECIFICATIONS

| Model | Cable Diameter -mm- | Breaking Strength -Lbs. | E | M |

| SHORT | ||||

| TG-050-24 | 12-15 | 4,500 | 8 | 21 |

| TG-062-24 | 15-18 | 5,600 | 8 | 24 |

| TG-075-24 | 18-25 | 6,800 | 9 | 24 |

| TG-100-24 | 25-37 | 9,600 | 9 | 24 |

| TG-150-24 | 37-50 | 16,400 | 11 | 24 |

| TG-200-24 | 50-63 | 18,500 | 12 | 24 |

| TG-250-24 | 63-75 | 24,500 | 12 | 26 |

| TG-300-24 | 75-88 | 24,500 | 14 | 28 |

| TG-350-24 | 88-101 | 31,000 | 14 | 30 |

| TG-400-24 | 101-114 | 32,000 | 15 | 32 |

| TG-450-24 | 114-127 | 34,000 | 16 | 34 |

| TG-500-24 | 127-152 | 36,000 | 18 | 36 |

| TG-600-24 | 152-177 | 38,000 | 20 | 38 |

| STANDARD | ||||

| TG-050-36 | 12-15 | 4500 | 8 | 36 |

| TG-075-36 | 18-25 | 6,800 | 9 | 36 |

| TG-100-36 | 25-37 | 9,600 | 9 | 36 |

| TG-150-36 | 37-50 | 16,400 | 11 | 36 |

| TG-200-36 | 50-63 | 18,500 | 12 | 36 |

| TG-250-36 | 63-75 | 24,500 | 12 | 36 |

| TG-300-36 | 75-88 | 24,500 | 14 | 36 |

| TG-350-36 | 88-101 | 31,000 | 14 | 40 |

| TG-400-36 | 101-114 | 32,000 | 15 | 42 |

| TG-450-36 | 114-127 | 34,000 | 16 | 44 |

| TG-500-36 | 127-152 | 36,000 | 17 | 46 |

| TG-600-24 | 152-177 | 38,000 | 18 | 48 |

| TG-600-36 | 152-177 | 38,000 | 18 | 48 |

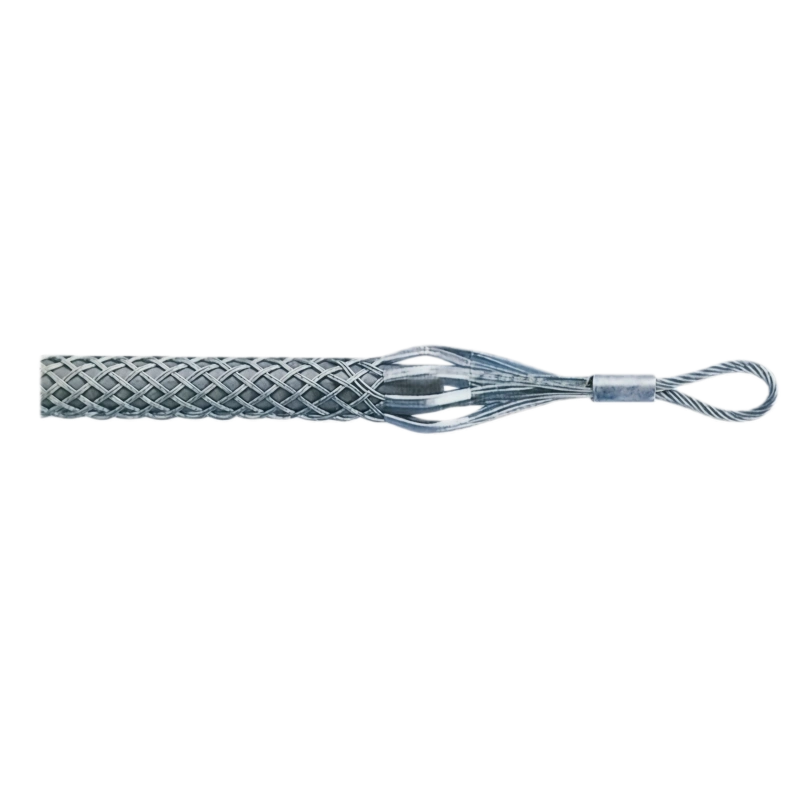

FEATURES OF CABLE PULLING GRIP SOCK

-

Medium Load Cable: Designed to handle medium-weight cables, providing secure and reliable pulls.

-

Flexible-Eye Design: Offers versatility in attachment, ensuring a smooth and secure pull.

-

High-Tensile Galvanized Steel: Built for durability and corrosion resistance, extending the lifespan of the grip.

-

Ideal for Industrial & Construction Applications: Perfect for heavy-duty environments requiring reliable cable handling.

INSTRUCTIONS & CAUTIONS

Inspect the Grip Before Each Use

Always check the cable pulling grip before use. Look for signs of wear or damage, such as frayed wires or bent components. Using a damaged grip can lead to slippage or even failure, so don’t take any risks. Regular inspections will help ensure the grip is in top condition and safe for the job.

Choose the Right Size for Your Cable

Make sure the cable pulling grip you’re using is the right size for your cable. A grip that’s too big or too small won’t provide a secure hold, which can cause problems during the pull. Check the manufacturer’s specifications for the correct grip size based on your cable’s diameter and weight to ensure optimal performance and safety.

Don’t Overload the Grip

Each cable pulling grip has a load limit. Exceeding that limit can cause the grip to fail, which might damage your cable or pulling equipment. Always check the grip’s load capacity and make sure it matches or exceeds the weight of the cable you’re pulling. Staying within the recommended limits ensures a safer, more effective operation.

Use the Grip with Proper Pulling Equipment

When using a cable pulling grip, ensure it’s attached to a suitable pulling system, such as a winch or hoist. The pulling equipment should be able to handle the load and be compatible with the grip. For smoother pulls, consider using a swivel in combination with the grip to reduce friction and prevent damage during the pull.

OUR ADVANTAGES

Custom Solutions Tailored to Your Needs

Every business has its unique requirements, and we’re here to meet them. We offer custom-engineered solutions designed to suit your specific needs. Our team works closely with you to deliver products tailored to your exact specifications, ensuring you get the best solution for your business challenges.

One-Stop Sourcing for Efficiency

We make sourcing easier by offering a complete range of lifting equipment solutions. Whether you need standard products or customized solutions, we provide everything under one roof. This approach helps you save time, reduces the hassle of dealing with multiple suppliers, and ensures you get exactly what you need, when you need it.

Unmatched Quality and Safety Standards

At Powerful Machinery, we prioritize quality and safety in every product. Our lifting equipment undergoes thorough inspections to meet the highest performance and safety standards. By using carefully selected materials and advanced manufacturing techniques, we ensure your equipment is reliable, durable, and safe for any project.

Exceptional After-Sales Support

Our commitment to your business doesn’t stop after the sale. Powerful Machinery offers comprehensive after-sales support to keep your equipment in top condition. Whether it’s troubleshooting, maintenance advice, or training, our dedicated customer service team is always ready to assist, ensuring smooth operations long after purchase.

FAQ

How do I use a cable pulling grip?

-

Place the Grip Around the Cable

Position the cable pulling grip around your cable, making sure the teeth hold it securely. -

Attach the Grip’s Eye to the Pulling System

Connect the eye of the grip to your pulling system, such as a winch or hoist. -

Check the Cable’s Alignment

Before starting the pull, verify that the cable is properly aligned and free from any obstacles that could interfere with the process. -

Verify the Grip’s Load Capacity

Always check the grip’s load capacity to ensure it matches the weight of the cable being pulled. This step is crucial to prevent accidents and ensure smooth operation.

Can cable pulling grips be used for different types of cables?

Yes, cable pulling grips are versatile and can handle various cable types, including power cables, communication cables, and fiber optics. The key is choosing the grip that matches your cable’s size and weight. Ensure the grip is compatible with your cable type to ensure a firm hold and smooth, efficient operation during the pull.

How do I select the correct cable pulling grip for my cable?

-

Consider the Cable’s Type, Size, and Weight

Identify the type, size, and weight of your cable. Make sure the grip is compatible with these factors to ensure a secure hold during the pull. -

Match the Grip’s Load Capacity to the Cable’s Weight

Ensure the grip’s load capacity aligns with the weight of the cable you’re pulling. The grip must be able to handle the cable’s load to prevent failure. -

Check the Cable’s Diameter

Select a grip that can accommodate the diameter of your cable. A grip that’s too small or too large will not perform effectively. -

Evaluate Environmental Factors

Assess the environment (indoor or outdoor use) to determine the material needed for the grip. Certain environments may require grips made from corrosion-resistant or durable materials. -

Refer to the Manufacturer’s Guidelines

Always check the manufacturer’s specifications to ensure the grip is the right match for your cable. The guidelines will provide essential details about size, load capacity, and material compatibility.

How do I maintain a cable pulling grip?

-

Store in a Dry Place

When not in use, store the cable pulling grip in a dry location to prevent moisture exposure, which can lead to rust and corrosion. -

Clean After Each Use

After using the grip, clean it thoroughly to remove dirt, debris, or any other build-up that may cause wear over time. -

Apply Protective Oil for Harsh Environments

If the grip is used in tough conditions, apply a light coat of protective oil to help prevent rust and ensure smooth operation. -

Inspect Regularly for Damage

Check the grip regularly for signs of damage, such as fraying or corrosion. If any damage is found, replace the grip immediately to maintain safety.

How do I attach a cable pulling grip to the pulling system?

-

Place the Grip Around the Cable

Position the cable pulling grip securely around the cable, ensuring it’s tightly fastened. -

Attach the Grip’s Eye to the Pulling System

Connect the eye of the grip to your pulling system, whether it’s a winch, hoist, or another pulling mechanism. -

Ensure a Tight and Stable Connection

Double-check that the connection between the grip and pulling system is tight and stable to prevent slippage during the pull. -

Align the Pulling System and Cable Properly

If using a winch or hoist, make sure the system is properly aligned with both the grip and cable to ensure smooth operation. -

Double-Check for Security Before Pulling

Before starting the pull, verify that all connections are secure and stable to ensure safety and efficient operation.