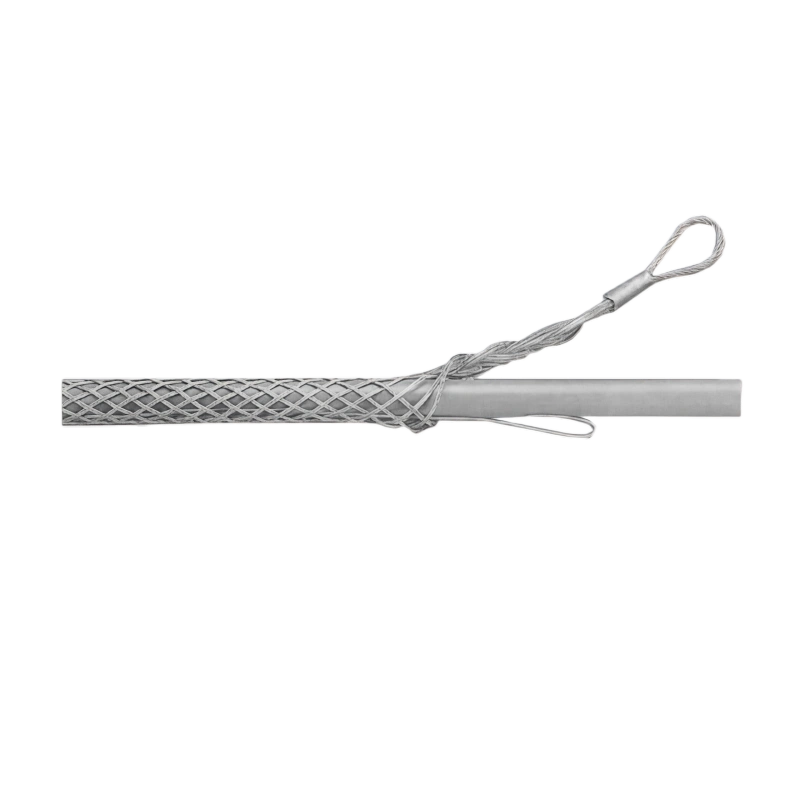

CABLE SOCK SPECIFICATIONS

| SPLIT MESH, SINGLE WEAVE –INGE– | ||||

| Model | Cable Diameter mm- | Breaking Strength -Lbs. | E | M |

| SK-075A | 18–25 | 2,500 | 7 | 12 |

| SK-100A | 25–32 | 3,500 | 8 | 15 |

| SK-125A | 32–37 | 4,000 | 8 | 16 |

| SK-150A | 37–50 | 4,000 | 9 | 17 |

| SK-200A | 50–63 | 4,000 | 10 | 19 |

| SK-250A | 63–75 | 4,000 | 10 | 20 |

| SK-300A | 75–88 | 4,000 | 12 | 21 |

| SK-350A | 88–101 | 4,000 | 12 | 22 |

| SK-400A | 101–114 | 4,800 | 12 | 23 |

| SK-450A | 114–127 | 5,000 | 12 | 24 |

| SK-500A | 127–152 | 5,200 | 12 | 25 |

| SK-600A | 152–177 | 5,400 | 12 | 26 |

FEATURES OF CABLE PULL SOCK

-

Single-Side Dragging Type & Wrap Grip: Ensures efficient cable handling and prevents slippage.

-

Multiple Size Options: Offers flexibility to fit a variety of cable diameters and applications.

-

High-Strength Galvanized Steel Mesh: Provides durable, long-lasting performance for heavy-duty pulls.

-

Customizable Weave & Length Designs: Available for tight spaces or higher-load tasks.

-

Versatile Applications: Perfect for underground cable pulling, utility work, and factory maintenance.

-

Quick, Easy Installation & Removal: No special tools required, saving time and labor costs.

-

Reusable: Built to withstand repeated use, offering long-term value.

-

Compatible with Swivels & Line Connectors: Easily attaches to various pulling systems for smooth operation.

INSTRUCTIONS & CAUTIONS

Secure the Sock Around the Cable Properly

Make sure to place the cable pulling sock around the cable securely. The mesh should hold the cable firmly, but avoid overtightening. A secure fit will prevent the sock from slipping or damaging the cable during the pull.

Check Size and Load Capacity Before Use

Verify that you’re using the correct size and load capacity for your cable. Using the wrong size can lead to instability or damage. Always refer to the manufacturer’s specifications to ensure you’ve chosen the right sock for your cable’s diameter and weight.

Inspect for Wear or Damage Before Each Use

Inspect the sock for any signs of damage such as fraying, tears, or mesh wear. If you find any issues, replace the sock immediately to maintain safety. Using a damaged sock could compromise your pull and potentially cause accidents.

Don’t Exceed the Recommended Load

Always make sure you’re not exceeding the sock’s recommended load capacity. Excessive force during a cable pull can stretch or break the sock, leading to unsafe conditions. Always match the pulling equipment to the sock’s rated capacity to ensure safe operation.

OUR ADVANTAGES

Exceptional Quality and Safety Standards

At Powerful Machinery, we prioritize safety and quality above all. We use carefully selected materials and conduct strict quality inspections at every stage. Our products meet industry standards, ensuring durability and performance. We believe in providing only the best, so you can trust our equipment for reliable, safe operations, every time.

One-Stop Sourcing and Custom Solutions

We offer a comprehensive, one-stop sourcing experience. From off-the-shelf products to custom-engineered solutions, Powerful Machinery delivers exactly what you need. Our team works closely with you to create tailored solutions that fit your unique specifications, ensuring efficient operations and reducing the hassle of dealing with multiple suppliers.

Efficient Logistics and On-Time Delivery

With our efficient logistics network, Powerful Machinery ensures fast and reliable delivery. We understand the importance of timely service, so we work hard to get your orders to you on schedule, minimizing delays in your operations. Our global reach allows us to support wholesalers and suppliers with a seamless and dependable supply chain.

Industry-Leading Customer Support

Customer satisfaction is our top priority. Powerful Machinery provides ongoing support before, during, and after the sale. Our knowledgeable team is always available to assist with product inquiries, technical questions, or any issues that arise. With our commitment to outstanding service, we make sure you get the support you need whenever you need it.

FAQ

How do I use a cable pulling sock?

-

Secure the Sock Around the Cable:

Start by placing the cable pulling sock around the cable, ensuring that the mesh grips the cable tightly and securely. -

Attach the Sock’s Eye to the Pulling System:

Next, attach the sock’s eye to your pulling system, such as a winch or hoist, ensuring the connection is firm and stable. -

Ensure Proper Cable Alignment:

Before you start pulling, make sure the cable is properly aligned and free from any obstacles to ensure smooth movement. -

Check the Sock’s Load Capacity:

Always verify the sock’s load capacity before beginning the pull. This step is crucial to avoid overloading and to ensure safe and efficient operation throughout the task.

How do I choose the right cable pulling sock for my cable?

-

Match Size and Load Capacity:

Select a cable pulling sock that matches the size and load capacity of your cable. Ensure the sock can handle the cable’s diameter and weight for a secure grip. -

Consider the Environment:

Evaluate the environment where you’ll be pulling the cable. Whether indoors or outdoors, weather conditions can impact the material and durability of the sock. -

Refer to Manufacturer Specifications:

Always consult the manufacturer’s specifications for the recommended sock size and load limits. This ensures proper compatibility with your cable. -

Ensure a Secure Fit:

Choose a sock that fits snugly around the cable. A properly sized sock ensures a secure grip, preventing slippage and minimizing the risk of damage during the pull.

How do I know if my cable pulling sock is damaged?

Inspect your cable pulling sock regularly for signs of damage, such as fraying, tears, or bent wires in the mesh. If the sock shows any signs of wear, it should be replaced immediately to ensure safety during future pulls. Regular inspection is key to preventing accidents, as using a damaged sock can compromise both the cable and the integrity of the pull.

Can I reuse a cable pulling sock?

Yes, you can reuse cable pulling socks as long as they remain in good condition. After each use, inspect for wear and tear, clean the sock, and store it properly. A well-maintained sock can last through multiple uses, making it a cost-effective solution for ongoing cable pulls. If any damage is found, replace it to ensure safe and efficient performance.

How do I clean a cable pulling sock?

-

Remove Dirt and Debris:

After each use, remove any dirt or debris from the cable pulling sock to prevent buildup. -

Wash with Mild Detergent:

If necessary, wash the sock with mild detergent and water. Avoid using harsh chemicals that could damage the mesh or weaken the fibers. -

Allow the Sock to Dry Completely:

After washing, ensure the sock is thoroughly dried before storage. This helps maintain its integrity and prevents any moisture-related damage. -

Store in a Cool, Dry Place:

Store the cleaned sock in a cool, dry location to prevent rust, mold, or corrosion. Proper storage ensures the sock stays in good condition for future use.

Can cable pulling socks be used with different pulling equipment?

Cable pulling socks are compatible with most standard pulling equipment like winches, hoists, and pulleys. The sock’s eye easily attaches to different connectors, including swivels and line-type connectors. This flexibility makes them versatile and easy to integrate into your existing pulling system, saving time and effort during the setup.

How do I store a cable pulling sock properly?

-

Store in a Clean, Dry Place:

After use, store your cable pulling sock in a clean, dry area to prevent rust or corrosion. -

Avoid Extreme Temperatures and Humidity:

Keep the sock away from areas exposed to extreme heat, cold, or humidity, as these conditions can damage the material. -

Ensure the Sock is Free from Dirt and Debris:

Before storage, remove any dirt or debris to prevent buildup that could affect the sock’s performance. -

Let the Sock Dry Completely:

Always let the sock dry fully before storing it to avoid moisture-related issues that could compromise its condition.