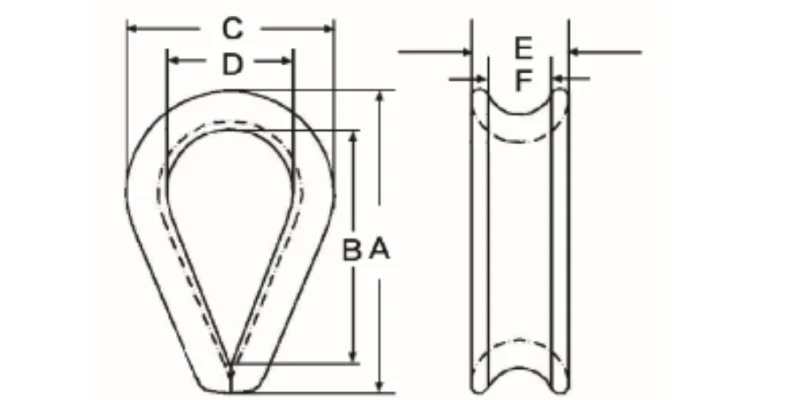

Product Specifications

| SIZE | DIMENSIONS(MM) | WEIGHT | |||||

| MM | A | B | C | D | E | F | KG/100PCS |

| 3 | 28 | 19 | 18.5 | 12 | 6 | 3 | 0.5 |

| 4 | 30 | 21 | 20.5 | 13 | 7 | 4 | 0.8 |

| 5 | 33 | 23 | 22.5 | 14 | 8 | 5 | 1 |

| 6 | 39 | 26 | 27 | 16 | 10 | 6 | 1.6 |

| 7 | 43 | 30 | 30 | 18 | 11 | 7 | 1.9 |

| 8 | 48 | 32 | 33 | 20 | 12 | 8 | 3 |

| 10 | 58 | 38 | 39 | 24 | 14 | 10 | 4.7 |

| 12 | 69 | 45 | 47 | 28 | 17 | 12 | 6.8 |

| 13 | 73 | 48 | 50 | 30 | 18 | 13 | 8 |

| 14 | 77 | 51 | 53 | 32 | 19 | 14 | 10 |

| 16 | 88 | 58 | 60 | 36 | 22 | 16 | 14.5 |

| 17 | 95 | 61 | 65 | 38 | 25 | 17 | 18 |

| 18 | 100 | 64 | 68 | 40 | 26 | 18 | 20 |

| 20 | 113 | 72 | 75 | 45 | 28 | 20 | 29 |

| 22 | 123 | 80 | 82 | 50 | 30 | 22 | 32 |

| 24 | 135 | 90 | 92 | 56 | 34 | 24 | 47 |

| 26 | 145 | 99 | 100 | 62 | 36 | 26 | 59 |

| 28 | 162 | 112 | 110 | 70 | 38 | 28 | 80 |

| 30 | 175 | 120 | 120 | 75 | 42 | 30 | 110 |

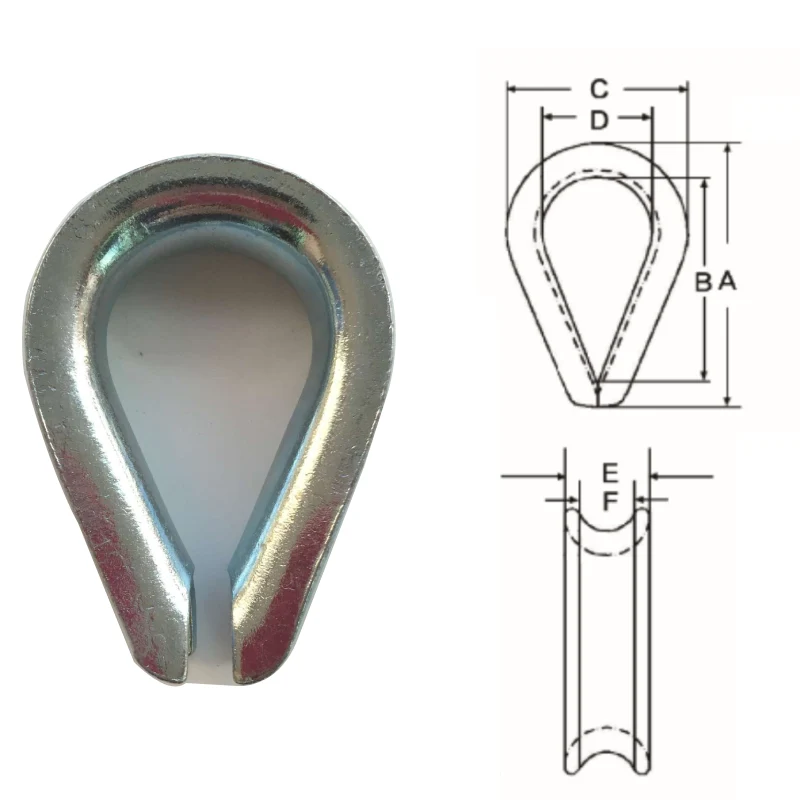

Products Diagrams

The DIN6899B Type Wire Rope Thimble features a thicker, deeper groove for heavy-duty applications, offering increased rope protection and strength during high-tension lifting or pulling operations.

This thimble’s robust build and smooth galvanized coating demonstrate its capacity to withstand demanding loads, providing reliable eye reinforcement under continuous stress.

Material Specification

Grade:

Produced from premium mild carbon steel to meet DIN 6899B standards, offering high load-bearing performance for industrial and marine rigging systems.

Finish:

Hot-dip galvanized surface resists rust and moisture, ensuring extended service life even under harsh weather or corrosive conditions.

Attachment:

Quick installation by looping the cable around the thimble groove and securing with wire rope clips or ferrules for a firm, safe connection.

DIN6899B Type Wire Rope Thimble Type:

Designed according to DIN 6899B heavy-duty specification, thicker and stronger than the Type A version for demanding lifting and pulling applications.

Material:

Manufactured in mild steel or optional stainless steel for extra corrosion resistance in marine and offshore environments.

Application

Construction Industry

Used in cranes, winches, and hoisting systems to prevent wire rope eye deformation during repeated lifting or tensioning tasks.

Marine & Offshore

Perfect for ship mooring, anchor line loops, and offshore rigging operations, where durability and corrosion resistance are critical.

Mining Industry

Essential for wire rope assemblies in mine hoists, pulley systems, and conveyor setups under heavy mechanical load and friction.

Advantages

Corrosion & Finish Protection

Thick galvanized finish prevents corrosion and surface damage, extending lifespan in outdoor and marine environments.

Customization & Traceability

Available in a full size range with OEM customization, batch tracking, and material certification for consistent quality control.

Load Control & Durability

Reinforced structure provides higher load resistance, minimizing rope wear and ensuring safe performance in heavy-duty use.

Bulk Capacity & Lead Time

Large-scale manufacturing ensures stable supply, competitive pricing, and short delivery cycles for global distributors and wholesalers.

What Our Clients Say

FAQ

What makes DIN6899B Type Wire Rope Thimbles different from Type A?

DIN6899B thimbles are thicker, heavier, and designed for demanding rigging jobs. Their reinforced groove structure provides extra strength and better wire rope protection under heavy loads.

How do I install a DIN6899B Type Thimble correctly?

Insert the thimble inside the wire rope loop, wrap the cable tightly around the groove, and secure it with wire rope clips or ferrules to maintain loop shape and tension.

Are these thimbles suitable for marine use?

Yes, our galvanized and stainless steel options resist corrosion, making them ideal for marine, offshore, and coastal applications with high moisture and salt exposure.

Can I order customized sizes or finishes?

Powerful Machinery offers customized diameters, surface treatments, and packaging to meet OEM or bulk order requirements.

What quality control measures are applied?

Each thimble undergoes load testing, dimension inspection, and surface quality checks. Full traceability is provided through batch codes and material certificates.

What sizes do you supply?

We supply DIN6899B thimbles from 4mm to 52mm. Custom dimensions are available for special lifting or rigging systems upon request.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.