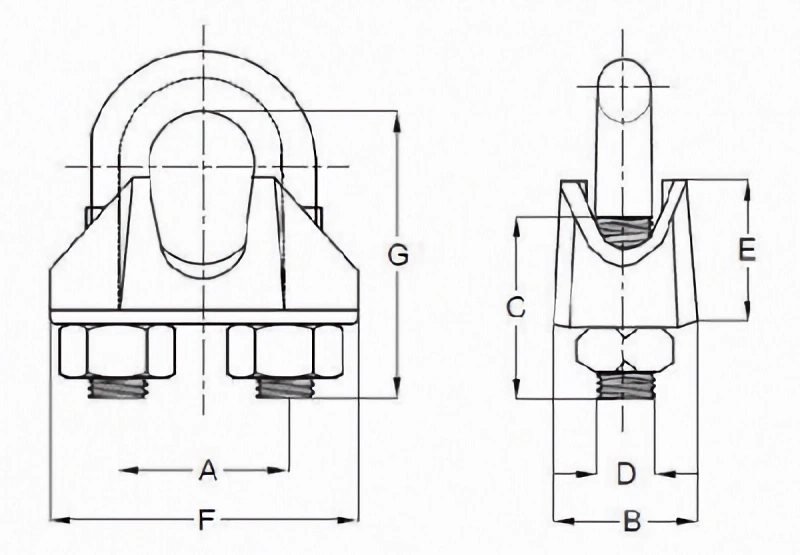

DIAGRAM

SPECIFICATIONS

| Item No. | Size | A | B | C | D | E | F | G |

| mm | mm | mm | mm | mm | mm | mm | mm | |

| PFSS74103 | 3 | 9 | 10 | 12 | 4 | 10 | 21 | 16 |

| PFSS74105 | 5 | 11 | 11 | 13 | 5 | 10 | 23 | 19 |

| PFSS74106 | 6 | 13 | 12 | 15 | 5 | 11 | 26 | 23 |

| PFSS74108 | 8 | 16 | 14 | 19 | 6 | 15 | 30 | 28 |

| PFSS74110 | 10 | 19 | 18 | 22 | 8 | 17 | 34 | 34 |

| PFSS74111 | 11 | 20 | 19 | 22 | 8 | 18 | 36 | 36 |

| PFSS74113 | 13 | 24 | 23 | 30 | 10 | 21 | 42 | 45 |

| PFSS74114 | 14 | 25 | 23 | 30 | 1 | 22 | 44 | 47 |

| PFSS74116 | 16 | 29 | 26 | 33 | 12 | 26 | 50 | 51 |

| PFSS74119 | 19 | 32 | 29 | 38 | 12 | 30 | 54 | 63 |

| PFSS74122 | 22 | 37 | 33 | 44 | 14 | 34 | 61 | 71 |

| PFSS74126 | 26 | 41 | 35 | 45 | 14 | 37 | 65 | 81 |

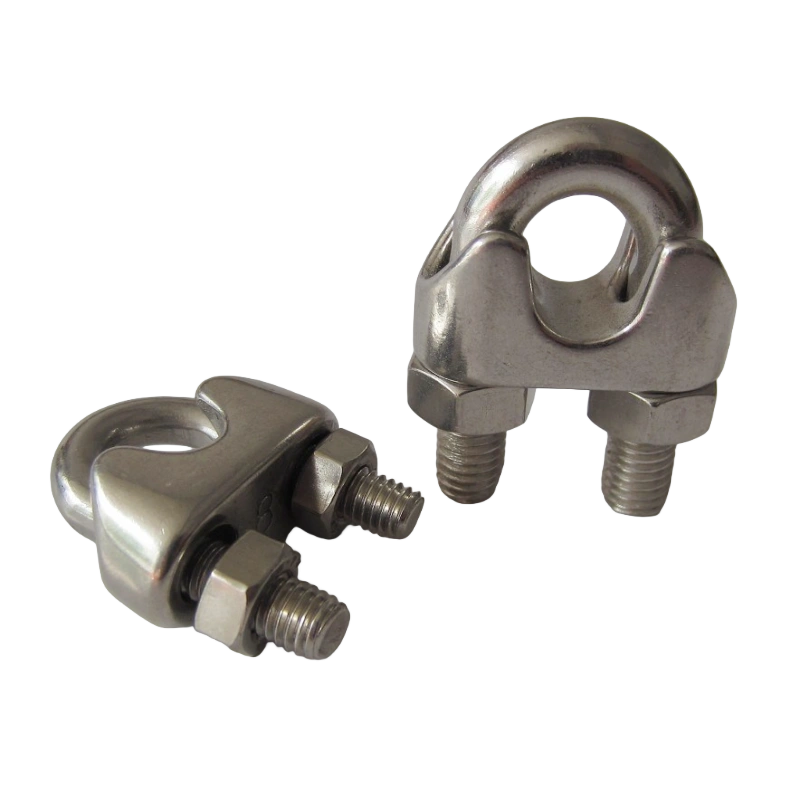

PRODUCT FEATURES

-

Made from AISI304 or AISI316 stainless steel for strength and corrosion resistance.

-

Polished finish for added durability and resistance to harsh conditions.

-

Available in diameters from 3mm to 26mm.

-

DIN741 compliant, ensuring reliability in marine and industrial settings.

-

Versatile for use in wire rope connections, eyelet formation, and static load suspension.

INSTRUCTIONS & CAUTIONS

Proper Installation & Torque Check

When installing your DIN741 wire rope clips, space them at least 6 wire rope diameters apart to ensure a secure hold. Tighten the clips before applying load to the rope. After the load is placed, re-tighten the clips to account for any slack or changes in rope tension. Regularly check the tightness of the nuts, especially after one week, one month, and then every 6 months.

Safety Factors & Load Limits

Always add a safety factor of 3-5 times the expected load to ensure safe operation. DIN741 wire rope clips should not be used for applications involving lifting people, conveyor systems in mining, or crane rope drives. Never exceed the recommended load limits; for critical applications, refer to detailed test reports available on the product page.

Wire Rope Compatibility

For optimal use, use wire rope clips with flexible 7×19 strand wire ropes. Avoid using them with stiff 1×19 or 7×7 strands, particularly in diameters 8mm or above. For each end, we recommend 3 clips for diameters up to 6mm and 4 clips for diameters from 8mm to 19mm. This ensures the correct load distribution and reliable connection.

Routine Inspections

To maintain safety, it is essential to inspect the wire rope clips regularly, especially when used in high-stress or severe conditions. Regular inspections are required to avoid risks like deformation or alteration of material structure. We recommend a minimum of every 6 months for standard conditions, with more frequent checks for higher risk environments.

OUR ADVANTAGES

Tailored Solutions for Your Needs

At Powerful Machinery, we focus on providing solutions that fit your specific requirements. We work closely with you to understand your needs, offering personalized support for everything from bulk orders to customizations. This level of attention ensures your projects run smoothly and efficiently, saving you time and improving your bottom line.

Reliable Product Quality with Consistent Supply

We understand the importance of quality and reliability in your operations. With Powerful Machinery, you can count on top-notch materials and durable products. Our strict quality control processes ensure that every order meets your exact specifications. Plus, we maintain a consistent supply chain to ensure timely deliveries, helping you keep your operations on track.

Expert Technical Support Every Step of the Way

We don’t just sell products—we’re here to support you through the entire process. From product selection to installation, our team of experts is ready to provide technical guidance and assistance whenever you need it. Whether you’re working on a large project or need advice on customizations, we’re always here to help.

Commitment to Competitive Pricing

At Powerful Machinery, we understand that cost efficiency is crucial for your business. That’s why we offer competitive pricing without compromising on quality. We work with you to find the best solution within your budget, offering flexible payment options and discounts on large orders to help you stay competitive in the market.

OUR REVIEWS

FAQ

What is the correct number of clips to use?

For wire ropes up to 6mm in diameter, use at least 3 clips per end. For ropes between 8mm and 19mm, 4 clips per end are recommended. Using the correct number ensures a secure connection and prevents failure under load. Always follow the manufacturer’s recommendation for optimal performance.

Are the clips reusable?

It’s generally not recommended to reuse DIN 741 wire rope clips. Over time, the clips may lose their holding power due to wear or deformation. Always use new clips if you’re redoing an installation or replacing damaged components for optimal security.

What is the maximum load these clips can handle?

The clips are designed to hold 50% of the wire rope’s breaking load as a guideline. Always make sure to use a 3-5 times safety factor for your application. For heavier loads, check with the manufacturer or use stronger hardware to ensure safety.

What is the maximum load these clips can handle?

The clips are designed to hold 50% of the wire rope’s breaking load as a guideline. Always make sure to use a 3-5 times safety factor for your application. For heavier loads, check with the manufacturer or use stronger hardware to ensure safety.

How do I choose the right size clip for my wire rope?

The correct clip size should match the wire rope diameter. For instance, if you’re using 5mm wire rope, select 5mm clips. Each clip allows the rope to pass through twice to form a loop. For the best results, always ensure the clips match the wire diameter for secure installation.