Product Specifications

| EUROPEAN TYPE LARGE BOW SHACKLE | |||||||

| SIZE | A | B | D | d | W | WLL(KGS) | WEIGHT |

| MM | MM | MM | MM | MM | MM | KG | 100 PCS/KG |

| 5 | 10 | 20 | 5 | 5 | 16 | 80 | 1.9 |

| 6 | 12 | 24 | 6 | 6 | 20 | 100 | 3.4 |

| 8 | 16 | 32 | 8 | 8 | 24 | 200 | 7 |

| 10 | 20 | 40 | 10 | 10 | 32 | 320 | 13 |

| 12 | 24 | 48 | 12 | 12 | 38 | 520 | 26 |

| 16 | 32 | 64 | 16 | 16 | 56 | 800 | 50 |

| 20 | 40 | 80 | 20 | 20 | 66 | 1100 | 80 |

| 22 | 44 | 88 | 22 | 22 | 74 | 1500 | 130 |

| 25 | 50 | 100 | 25 | 25 | 80 | 2100 | 200 |

| 28 | 56 | 112 | 28 | 28 | 94 | 3000 | 300 |

| 32 | 64 | 118 | 32 | 32 | 104 | 3500 | 430 |

| 38 | 76 | 152 | 38 | 38 | 126 | 5000 | 700 |

| 45 | 90 | 180 | 45 | 45 | 150 | 7000 | 1250 |

| 50 | 100 | 200 | 50 | 50 | 156 | 8000 | 1750 |

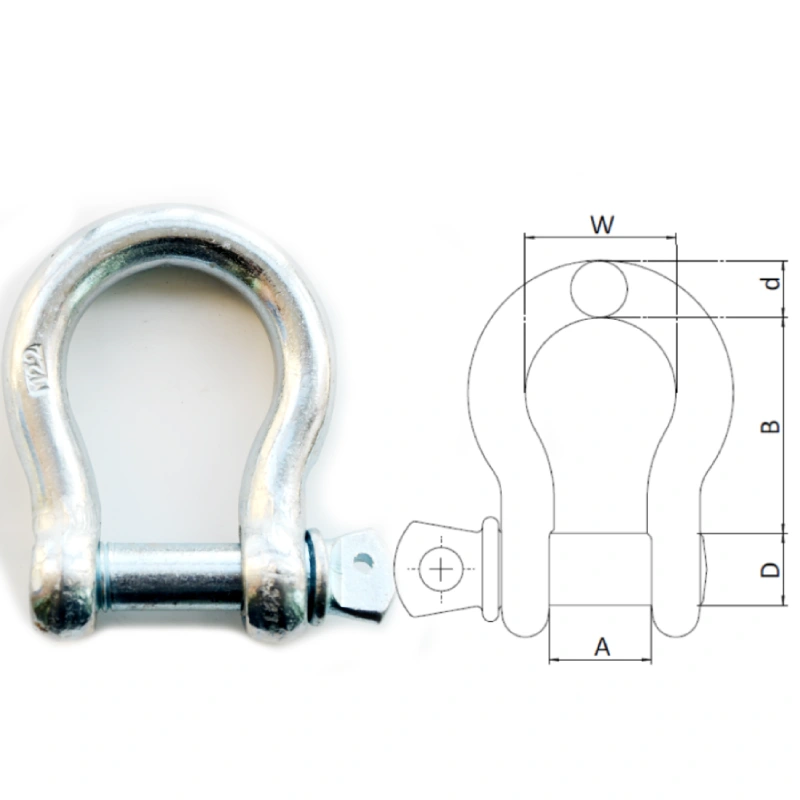

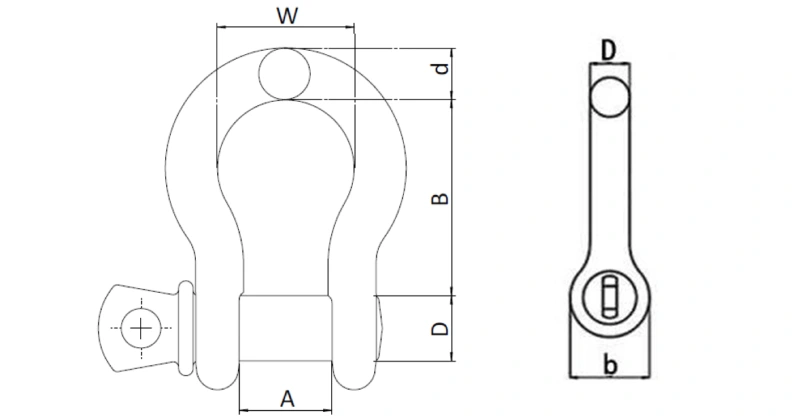

Products Diagrams

The wide “bow” shape allows multiple sling connections without reducing load capacity. The forged steel body and smooth pin threading ensure safety and long service life.

The drop-forged pin and body—both made from the same diameter steel for balanced load distribution and superior fatigue strength. The precision threading allows quick assembly and disassembly.

Material Specification

Grade:

Complies with European standard EN 13889, offering consistent mechanical strength and load-bearing safety across lifting operations.

Finish:

Hot-dip galvanized or electro-galvanized surface treatment enhances resistance to corrosion, maintaining high performance in outdoor and marine conditions.

Attachment:

Designed for easy attachment to wire ropes, chains, and lifting slings. The large bow design supports angle or side pull applications.

Hook Type:

Features a round pin or screw pin connection, offering quick and secure linkage in both temporary and permanent lifting setups.

Material:

Made from high-tensile carbon steel, drop-forged and heat-treated to ensure structural integrity and durability under heavy industrial use.

Application

Construction Industry

Ideal for crane lifting, hoisting, and load securing on construction sites requiring heavy-duty performance and quick attachment.

Marine & Offshore

Used for towing, mooring, and anchoring due to its large bow and corrosion-resistant finish that withstands saltwater exposure.

Mining Industry

Supports material handling, haulage, and lifting operations in harsh environments where shock load and vibration resistance are critical.

Advantages

Corrosion & Finish Protection

Galvanized coating shields against rust and abrasion, extending lifespan and reducing replacement costs in demanding conditions.

Customization & Traceability

Custom sizes, markings, and traceable production batches available to support OEM brands and industrial compliance needs.

Load Control & Durability

Forged from high-strength steel, ensuring consistent performance under variable loads and minimizing deformation risks.

Bulk Capacity & Lead Time

High-volume production capacity with efficient logistics ensures reliable global supply and short lead times for distributors.

What Our Clients Say

FAQ

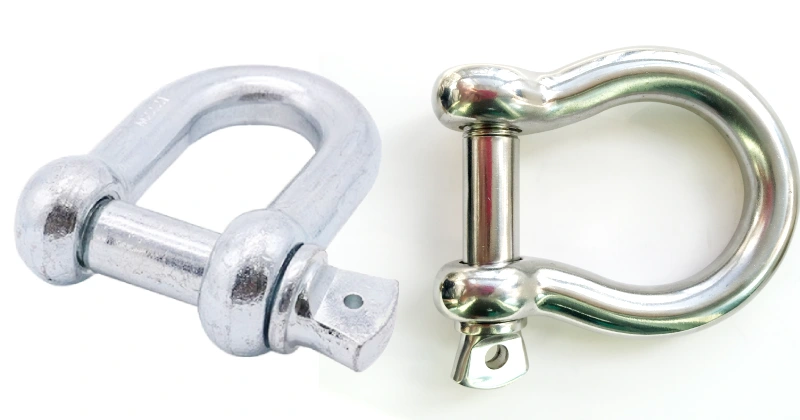

What makes the European Type Large Bow Shackle different from a Dee Shackle?

The bow shackle has a wider “O” shape, allowing multiple sling connections and angular loading. Dee shackles are better for straight-line pulls, while bow shackles provide flexibility for varied load directions.

Can this shackle be used in marine applications?

Yes, it’s designed for marine and offshore use. The galvanized surface prevents corrosion, and the drop-forged structure withstands seawater exposure and high humidity.

Are custom markings or colors available?

Yes. We provide OEM customization, including logo engraving, size markings, and color-coded finishes for brand visibility and safety classification.

What load range do you offer?

We supply shackles from 0.33T to over 55T Working Load Limit (WLL). Each product undergoes proof load testing and quality inspection for full traceability.

What’s the lead time for bulk orders?

Standard production lead time is 3–5 weeks. However, we keep stock of popular sizes for faster shipment to distributors and repeat clients.

How should the Large Bow Shackle be installed for safety?

Ensure the load is centered in the bow and avoid over-tightening the pin. Always check for wear, corrosion, or deformation before each use.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.