Product Specifications

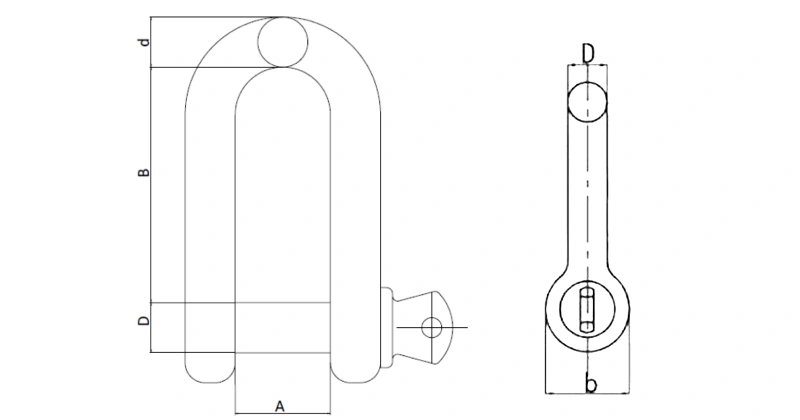

| EUROPEAN TYPE LARGE DEE SHACKLE | ||||||

| SIZE | A | B | D | d | WLL(KGS) | WEIGHT |

| MM | MM | MM | MM | MM | KG | 100 PCS/KG |

| 5 | 10 | 20 | 5 | 5 | 80 | 1.85 |

| 6 | 12 | 24 | 6 | 6 | 100 | 3.3 |

| 8 | 16 | 32 | 8 | 8 | 200 | 6.8 |

| 10 | 20 | 40 | 10 | 10 | 320 | 12.6 |

| 12 | 24 | 48 | 12 | 12 | 520 | 23 |

| 16 | 32 | 64 | 16 | 16 | 800 | 48.5 |

| 20 | 40 | 80 | 20 | 20 | 1100 | 78 |

| 22 | 44 | 88 | 22 | 22 | 1500 | 126 |

| 25 | 50 | 100 | 25 | 25 | 2100 | 194 |

| 28 | 56 | 112 | 28 | 28 | 3000 | 291 |

| 32 | 64 | 118 | 32 | 32 | 3500 | 417 |

| 38 | 76 | 152 | 38 | 38 | 5000 | 655 |

| 45 | 90 | 180 | 45 | 45 | 7000 | 1213 |

| 50 | 100 | 200 | 50 | 50 | 8000 | 1698 |

Products Diagrams

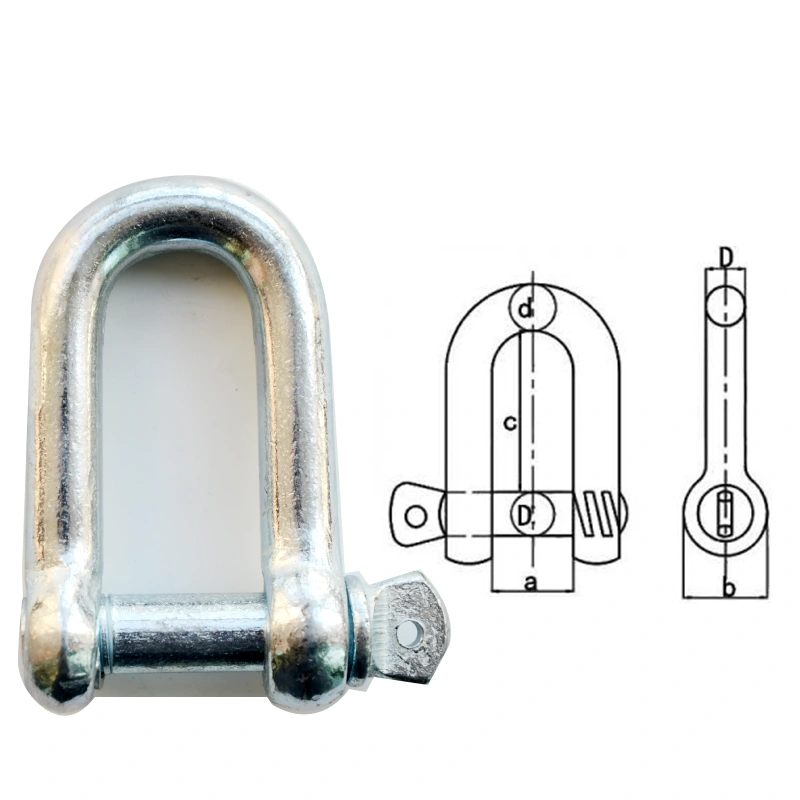

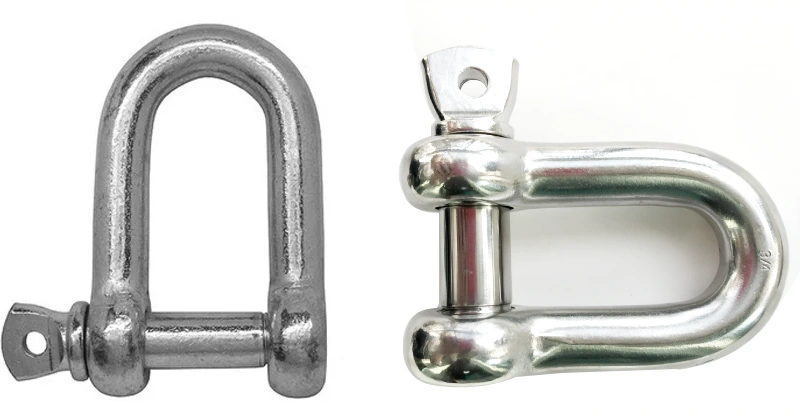

The side profile highlights the Dee shape designed for straight-line tension. The forged steel body and threaded pin provide high load capacity and consistent performance for lifting and towing applications.

A detailed angle showcases the even pin and body diameter—precision-engineered for load stability and durability. The screw pin design ensures secure fastening and easy removal in repeated use.

Material Specification

Grade:

Conforms to European Standard EN 13889 and meets international load testing requirements, ensuring long-term safety in industrial lifting applications.

Finish:

Hot-dip galvanized or electro-zinc plated finish delivers excellent corrosion protection and a smooth surface for improved wear resistance.

Attachment:

Easily connects with steel chains, lifting slings, and wire ropes for secure rigging setups in straight-pull operations.

Hook Type:

Features a screw pin or bolt-type closure system for flexibility between temporary and semi-permanent installations.

Material:

Manufactured from drop-forged carbon steel, heat-treated for extra strength, and proof-load tested for consistent performance under heavy loads.

Application

Construction Industry

Used in crane hoisting, rigging, and structural lifting where precise load control and safety compliance are essential.

Marine & Offshore

Ideal for mooring, towing, and anchoring, offering resistance to corrosion and vibration in saltwater environments.

Mining Industry

Supports lifting and haulage systems under harsh, high-impact conditions with proven mechanical endurance.

Advantages

Corrosion & Finish Protection

Durable galvanized finish shields against rust, ensuring a longer working life even in moisture-heavy environments.

Customization & Traceability

Custom markings, OEM branding, and batch traceability provide compliance and easy inventory management.

Load Control & Durability

Forged and tested for high tensile strength to maintain consistent load performance under maximum working limits.

Bulk Capacity & Lead Time

High-volume production and efficient logistics ensure quick lead times and reliable global delivery for distributors.

What Our Clients Say

FAQ

What is the main use of the European Type Large Dee Shackle?

It’s primarily used for straight-line lifting or towing applications. Its D-shape design prevents bending and ensures a direct pull, making it suitable for single-leg slings, hoisting chains, and load securing systems.

Can the Dee Shackle be used for multi-leg slings?

It’s not recommended. Dee shackles are best suited for straight-line loads. For multi-leg configurations or angled pulls, we recommend a Large Bow Shackle, which provides better side-load handling.

Are your shackles tested before delivery?

Yes, every shackle undergoes proof load and tensile testing according to EN 13889 standards. We also offer third-party inspection reports (SGS, BV, or Lloyd’s) upon request.

What sizes and load capacities are available?

We supply shackles with Working Load Limits (WLL) ranging from 0.33T to 55T. Custom dimensions are also available for OEM and project-specific requirements.

How long does production and delivery take?

Standard orders ship within 15–25 days. Bulk and customized orders may take 25–35 days depending on quantity and specification.

Do you provide OEM services for distributors?

We offer OEM and branding solutions, including logo engraving, color coding, and custom packaging to support international distribution channels.

How should I maintain the Dee Shackle for long-term use?

Inspect the shackle regularly for corrosion, deformation, or thread wear. Clean and lightly oil the pin threads. Replace the unit immediately if any damage or bending is found to ensure lifting safety.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.