Product Specifications

| G-403 JAW END SWIVELS | ||||||||||||||||

| SIZE | WLL | WEIGHT | DIMENSIONS(IN.) | |||||||||||||

| IN. | LBS | LBS | A | B | C | G | J | K | L | M | N | P | R | T | U | V |

| 1/4″ | 850 | 0.21 | 1.25 | 0.69 | 0.75 | 0.69 | 0.69 | 0.47 | 1.03 | 0.31 | 0.88 | 0.25 | 2.63 | 3.38 | 1.69 | 1.69 |

| 5/16″ | 1250 | 0.34 | 1.63 | 0.81 | 1.00 | 0.81 | 0.81 | 0.50 | 1.13 | 0.38 | 0.88 | 0.31 | 2.94 | 3.88 | 2.06 | 1.81 |

| 3/8″ | 2250 | 0.66 | 2.00 | 0.94 | 1.25 | 1.00 | 1.00 | 0.63 | 1.41 | 0.50 | 1.06 | 0.38 | 3.63 | 4.75 | 2.50 | 2.25 |

| 1/2″ | 3600 | 1.34 | 2.50 | 1.31 | 1.50 | 1.31 | 1.31 | 0.75 | 1.75 | 0.63 | 1.31 | 0.50 | 4.50 | 6.06 | 3.19 | 2.88 |

| 5/8″ | 5200 | 2.48 | 3.00 | 1.56 | 1.75 | 1.63 | 1.50 | 0.94 | 2.06 | 0.75 | 1.50 | 0.63 | 5.31 | 7.31 | 3.88 | 3.44 |

| 3/4″ | 7200 | 3.88 | 3.50 | 1.75 | 2.00 | 1.88 | 1.88 | 1.13 | 2.53 | 0.88 | 1.75 | 0.75 | 6.06 | 8.31 | 4.31 | 4.00 |

| 7/8″ | 10000 | 5.87 | 4.00 | 2.06 | 2.25 | 2.13 | 2.13 | 1.19 | 2.75 | 1.00 | 2.06 | 0.88 | 7.00 | 9.53 | 5.00 | 4.53 |

| 1″ | 12500 | 9.84 | 4.50 | 2.31 | 2.50 | 2.63 | 2.38 | 1.75 | 3.72 | 1.13 | 2.81 | 1.13 | 8.56 | 11.69 | 5.75 | 5.94 |

| 1-1/4″ | 18000 | 15.75 | 5.69 | 2.69 | 3.13 | 3.13 | 3.00 | 2.06 | 4.31 | 1.50 | 2.81 | 1.38 | 9.44 | 13.13 | 6.75 | 6.38 |

| 1-1/2″ | 45200 | 54.75 | 7.00 | 4.19 | 4.00 | 5.63 | 4.00 | 2.88 | 6.00 | 2.25 | 4.44 | 2.25 | 14.74 | 20.84 | 10.00 | 10.84 |

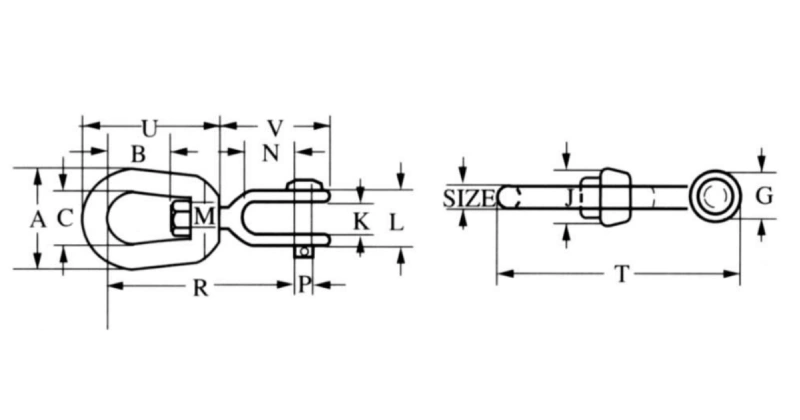

Products Diagrams

The G-403 Jaw End Swivel shows its solid forged steel body and precision-machined jaw connection. The smooth pin and secure cotter design ensures consistent load rotation without tension distortion, making it suitable for high-torque rigging systems.

The swivel reveals its full-length rotation mechanism and uniform galvanization coating. This durable construction prevents wear under continuous use and heavy load conditions, ensuring smooth movement and extended service life even in harsh offshore or dusty environments.

Material Specification

Grade:

Manufactured from Grade 40 forged steel, ensuring superior tensile strength and load performance under continuous rigging operations. Ideal for heavy-duty lifting and rotation tasks.

Finish:

Hot-dipped galvanized coating provides long-term corrosion protection against saltwater, chemicals, and outdoor exposure, maintaining performance and appearance over time.

Attachment:

Equipped with a secure clevis jaw end and removable pin for quick, safe attachment to chains, hooks, or wire ropes during rigging or lifting operations.

Jaw End Swivels Type:

Rotating jaw-to-eye connection type that allows 360° rotation, reducing twisting stress on ropes and cables in dynamic lifting applications.

Material:

High-carbon forged steel with precision machining ensures consistency, mechanical strength, and high impact resistance in both static and dynamic loads.

Application

Construction Industry

Used in cranes, scaffolding, and rigging assemblies, the G-403 Jaw End Swivel improves lifting safety by allowing controlled load rotation without damaging cables or chains.

Marine & Offshore

Essential for ships, docks, and offshore rigs, it prevents wire rope tangling and offers excellent saltwater corrosion resistance for continuous maritime operations.

Mining Industry

Handles extreme loads in hoisting systems, offering high durability and safe rotational movement under harsh underground or open-pit mining conditions.

Advantages

Corrosion & Finish Protection

Hot-dipped galvanization shields the surface from rust and abrasion, extending service life even in marine and chemical-exposed environments.

Customization & Traceability

Available in custom sizes with full load certification and traceable batch numbers to meet ISO and EN rigging standards.

Load Control & Durability

Forged steel structure provides stable load control, minimizing twisting and maintaining safety under heavy, continuous rigging pressure.

Bulk Capacity & Lead Time

Large-scale production enables fast delivery and competitive bulk pricing for global distributors and industrial equipment manufacturers.

What Our Clients Say

FAQ

What materials are used for your G-403 Jaw End Swivels?

We use forged high-carbon steel with a hot-dipped galvanized finish. This combination ensures exceptional tensile strength, rust protection, and long-lasting performance in both indoor and outdoor industrial environments.

Can you provide load capacity certification for each batch?

Yes. Each batch is accompanied by test reports, load capacity certificates, and traceability documentation, ensuring compliance with international safety and quality standards for lifting and rigging components.

Do you offer custom sizes or finishes for OEM customers?

We provide OEM and ODM customization, including alternative finishes such as electro-galvanized or stainless steel, along with personalized branding for distributors and large equipment suppliers.

How soon can bulk orders be delivered?

Standard orders are shipped within 2–3 weeks, while customized bulk orders are typically completed within 4–5 weeks depending on volume and complexity. We prioritize export-ready packaging for fast global delivery.

Are your swivels suitable for marine and offshore environments?

Yes. The hot-dip galvanization provides maximum corrosion resistance against saltwater and humidity. Our G-403 swivels are widely used in shipyards, ports, and offshore platforms.

What makes Powerful Machinery a trusted supplier?

With over 15 years of manufacturing expertise, Powerful Machinery has earned global trust through consistent quality, fast delivery, competitive pricing, and compliance with ASTM, ASME, and EN standards.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.