Product Specifications

| G100 FORGED MASTER LINK | |||||||

| SIZE | WEIGHT | WLL | CHAIN SIZE(MM) | A | B | D | |

| MM | KG/PC | TON | 1 LEG | 2 LEG | MM | MM | MM |

| 13 | 0.34 | 2.3 | 6/7 | 6 | 110 | 60 | 13 |

| 16 | 0.53 | 3.5 | 8 | 7 | 110 | 60 | 16 |

| 18 | 0.86 | 5 | 10 | 8 | 135 | 75 | 18 |

| 23 | 1.6 | 7.6 | 13 | 10 | 160 | 90 | 23 |

| 27 | 2.46 | 10 | 16 | 13 | 180 | 100 | 27 |

| 33 | 4.14 | 14 | 19 | 16 | 200 | 110 | 33 |

| 36 | 6.22 | 25.1 | 22 | 19 | 260 | 140 | 36 |

| 45 | 12.85 | 30.8 | 26 | 22 | 340 | 180 | 45 |

| 50 | 16.22 | 40 | 32 | 26 | 350 | 190 | 50 |

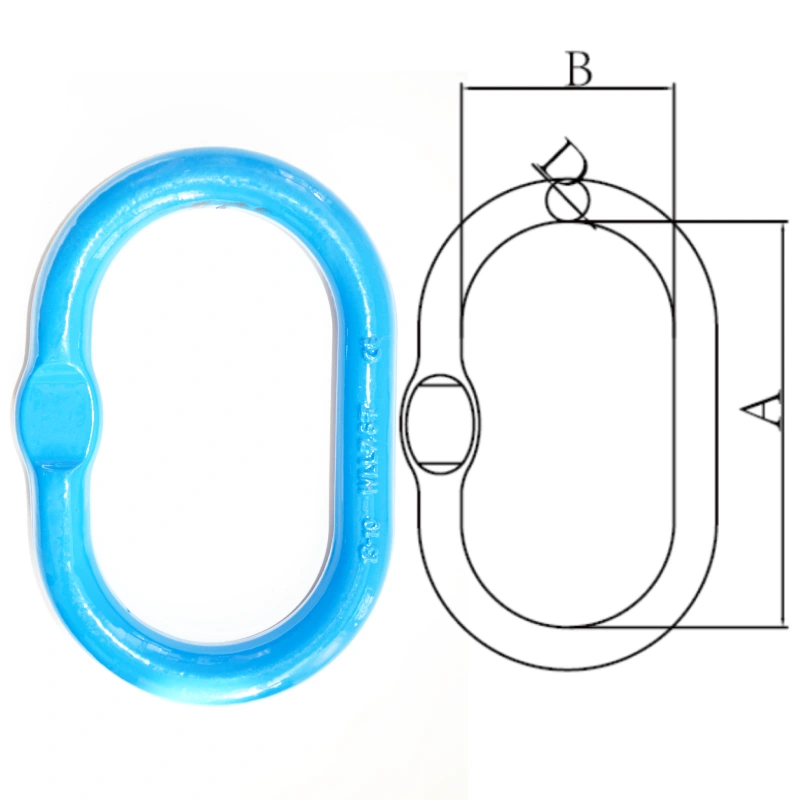

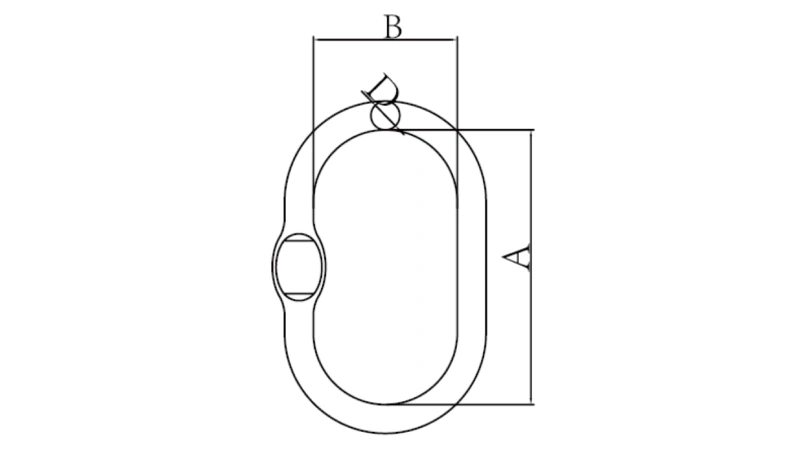

Products Diagrams

The G100 Forged Master Link shows a uniform oval shape with precise forging. This design helps distribute load evenly, reducing stress points and improving safety for heavy lifting.

The solid thickness and seamless forging. The smooth finish reduces wear on chains and slings, making it ideal for long-term industrial use under extreme conditions.

Material Specification

Grade: Manufactured with Grade 100 alloy steel, providing 25% higher strength than Grade 80 links, ensuring superior load-bearing performance.

Finish: Supplied with powder-coated or painted finish, offering corrosion resistance and longer working life even in harsh environments.

Attachment: Designed for chain sling and wire rope assemblies, compatible with single-leg and multiple-leg lifting setups.

Hook Type: Works seamlessly with clevis and eye-type hooks, offering versatility in rigging applications across industries.

Material: Forged from high-grade alloy steel, ensuring reliability, toughness, and durability for demanding lifting jobs.

Application

Construction Industry

Used in lifting concrete beams, steel frames, and heavy machinery with maximum safety and stability in on-site operations.

Marine & Offshore

Provides reliable lifting and mooring solutions for shipyards, oil rigs, and offshore equipment under extreme sea conditions.

Mining Industry

Handles bulk material movement, machinery lifting, and safety-critical operations in rugged and heavy-duty mining environments.

Advantages

Corrosion & Finish Protection

Special coatings prevent rust and extend service life, reducing maintenance costs for long-term industrial use.

Customization & Traceability

Available in customized sizes, with batch traceability for quality assurance, meeting international safety standards.

Load Control & Durability

High-grade forging ensures stable load control, superior durability, and peace of mind for critical lifting operations.

Bulk Capacity & Lead Time

We offer strong production capacity, fast delivery, and stable supply, meeting wholesale and project-based bulk requirements.

Supporting Products

Alloy Steel Chains

Heavy-duty chains designed for industrial lifting and rigging applications.

Pulleys & Blocks

High-strength pulleys for load handling and mechanical lifting systems.

FAQ

What makes the G100 Forged Master Link different from G80?

The G100 Forged Master Link is 25% stronger than Grade 80, providing higher working load limits. This makes it suitable for demanding industries like offshore, mining, and construction, where safety and strength are critical.

Can I request customized sizes or finishes?

Yes. As a manufacturer, Powerful Machinery offers custom sizes, finishes, and branding options. We also provide OEM/ODM services to meet bulk order requirements for distributors and large-scale buyers.

Is your G100 Forged Master Link certified?

Our products are manufactured under strict international standards such as EN and ISO, ensuring compliance, safety, and traceability for global markets.

What industries most commonly use G100 Forged Master Links?

They are widely used in construction, marine, offshore, logistics, and mining. These industries require safe and strong lifting solutions, making G100 links the preferred choice.

What is your delivery capacity for bulk orders?

We maintain high production capacity, ensuring fast delivery and reliable supply chains. Most bulk orders ship within 3–5 weeks, depending on order size and customization.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.