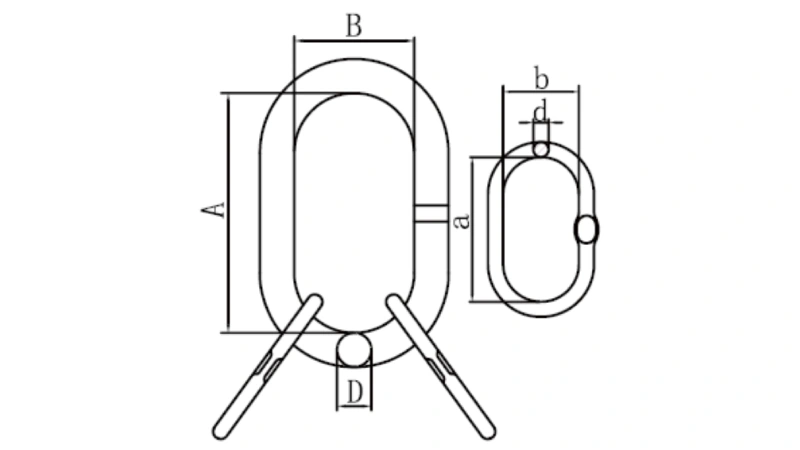

Product Specifications

| G100 MASTER LINK ASSEMBLY | ||||||||||

| SIZE | WEIGHT | WLL | CHAIN SIZE(MM) | A | B | D | a | b | d | |

| MM | KG/PC | TON | 3 OR 4 LEG | MM | MM | MM | MM | MM | MM | |

| 6 | 1.3 | 3 | 6 | 135 | 75 | 19 | 84 | 25 | 13 | |

| 8 | 2.33 | 5.3 | 8 | 160 | 90 | 23 | 70 | 35 | 16.5 | |

| 10 | 3.7 | 8 | 10 | 180 | 100 | 27 | 85 | 40 | 19 | |

| 13 | 6.5 | 14 | 13 | 200 | 110 | 33 | 115 | 50 | 23 | |

| 16 | 10.1 | 21.2 | 16 | 260 | 140 | 36 | 140 | 65 | 27 | |

| 20 | 22.8 | 33.6 | 20 | 350 | 190 | 50 | 150 | 70 | 33 | |

| 22 | 26 | 33.9 | 22 | 350 | 190 | 50 | 180 | 100 | 36 | |

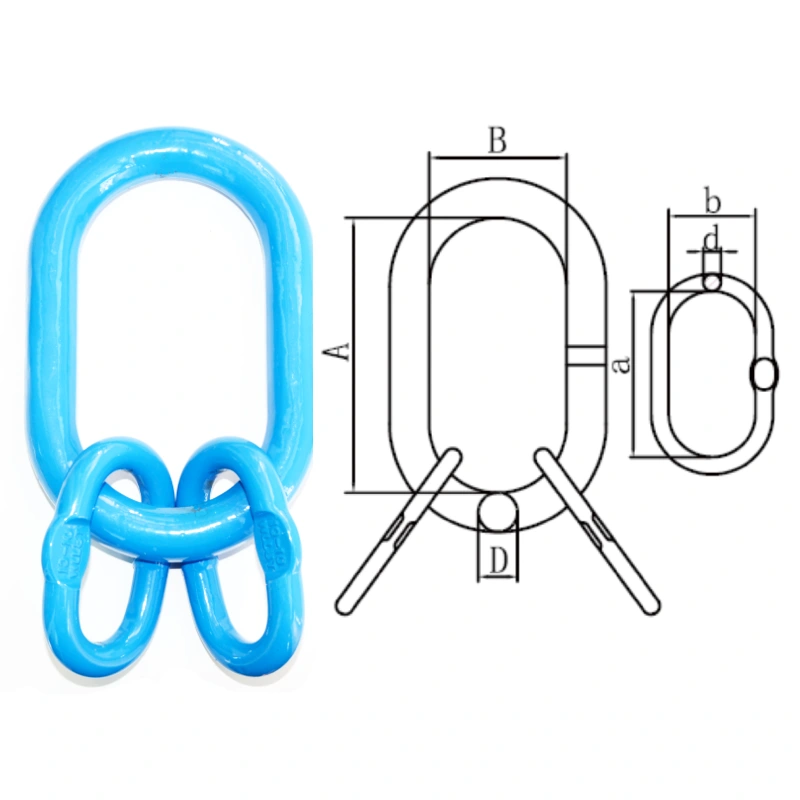

Products Diagrams

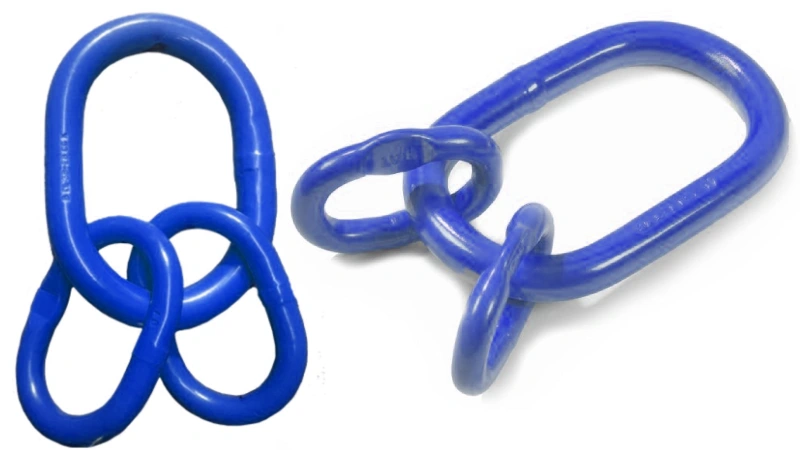

The G100 Master Link Assembly shows one large ring with two intermediate links inside. This design distributes load evenly, making it suitable for multiple-leg lifting systems with higher stability.

The solid forging and seamless construction are clear. The thickness and smooth finish minimize wear, ensuring long-term use in demanding environments such as offshore, mining, and construction.

Material Specification

Grade: Engineered with Grade 100 alloy steel, offering 25% more strength than Grade 80, ensuring safety under heavy lifting.

Finish: Protected with durable coating against rust and wear, extending service life in outdoor and marine environments.

Attachment: Designed to connect two, three, or four sling legs, making it versatile for industrial lifting solutions.

Hook Type: Works with clevis or eye-type hooks, giving flexibility across different rigging systems.

Material: Forged from premium alloy steel, ensuring toughness, durability, and compliance with international safety standards.

Application

Construction Industry

Ideal for lifting beams, concrete blocks, and heavy machinery with maximum safety and balanced load control.

Marine & Offshore

Used for rigging, shipyard operations, and offshore platform lifting, ensuring reliability in harsh sea conditions.

Mining Industry

Handles rugged lifting jobs like moving mining equipment and bulk materials under demanding conditions.

Advantages

Corrosion & Finish Protection

Rust-resistant coating reduces maintenance costs and ensures long service life in challenging environments.

Customization & Traceability

Available in custom sizes with batch traceability, giving buyers confidence in safety and quality control.

Load Control & Durability

Forged Grade 100 steel ensures higher working load limits with reliable strength and durability.

Bulk Capacity & Lead Time

Large-scale production ensures fast delivery and stable supply for bulk orders worldwide.

What Our Clients Say

FAQ

What is the main use of a G100 Master Link Assembly?

It is designed to connect multiple sling legs, making it suitable for 2, 3, or 4-leg chain and wire rope slings. This allows safe and efficient lifting in heavy-duty industries like construction, marine, and mining.

Why choose Grade 100 instead of Grade 80?

Grade 100 steel provides 25% higher strength, allowing heavier loads with smaller, lighter assemblies. This improves efficiency, reduces fatigue on lifting gear, and ensures better safety margins for industrial lifting.

Do you offer custom sizes or branding?

Yes, Powerful Machinery provides both standard and customized assemblies. We also offer OEM/ODM services, including private branding, to meet distributors’ and large buyers’ needs.

What certifications do your assemblies carry?

Our G100 Master Link Assemblies comply with international standards such as EN and ISO. Each batch comes with traceability and quality assurance for maximum buyer confidence.

What is your production and delivery capacity?

We maintain strong manufacturing capacity to meet bulk demand. Most standard orders ship within 3–4 weeks, while customized products may take 4–6 weeks depending on specifications.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.