Product Specifications

| G80 CLEVIS CLUTCH | |||||||||||

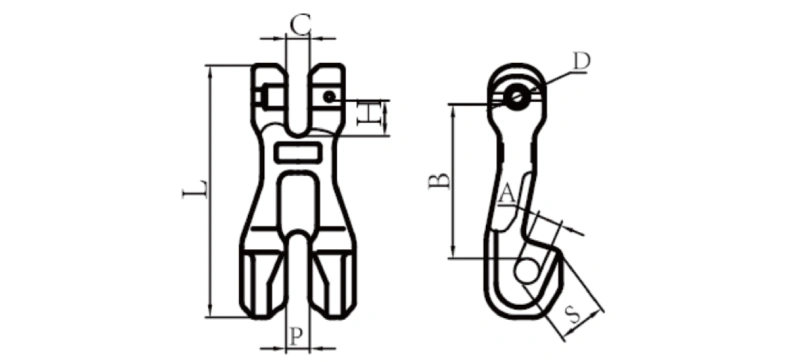

| SIZE | WEIGHT | WLL | B.L | P | C | A | B | H | S | L | D |

| MM | KG/PC | TON | TON | MM | MM | MM | MM | MM | MM | MM | MM |

| 6 | 0.17 | 1.12 | 4.48 | 7.5 | 7.5 | 8 | 44 | 10.3 | 12 | 73.5 | 7.8 |

| 7/8 | 0.37 | 2 | 8 | 9.5 | 9.5 | 10.5 | 61.7 | 14 | 17 | 101 | 9.2 |

| 10 | 0.97 | 3.15 | 12.6 | 13 | 13 | 12.4 | 92 | 18.4 | 28 | 138 | 13.2 |

| 13 | 2.01 | 5.3 | 21.2 | 16.5 | 16.5 | 16 | 115 | 22.7 | 34.5 | 177 | 16.2 |

| 16 | 3.32 | 8 | 32 | 21 | 21 | 19.5 | 143 | 28.5 | 40 | 220 | 20 |

| 20 | 6.2 | 12.5 | 50 | 23.5 | 23.5 | 23 | 152 | 33.6 | 46 | 238 | 24.3 |

| 22 | 8.5 | 15 | 60 | 25.5 | 25.5 | 26 | 195 | 39 | 57.5 | 295 | 28.1 |

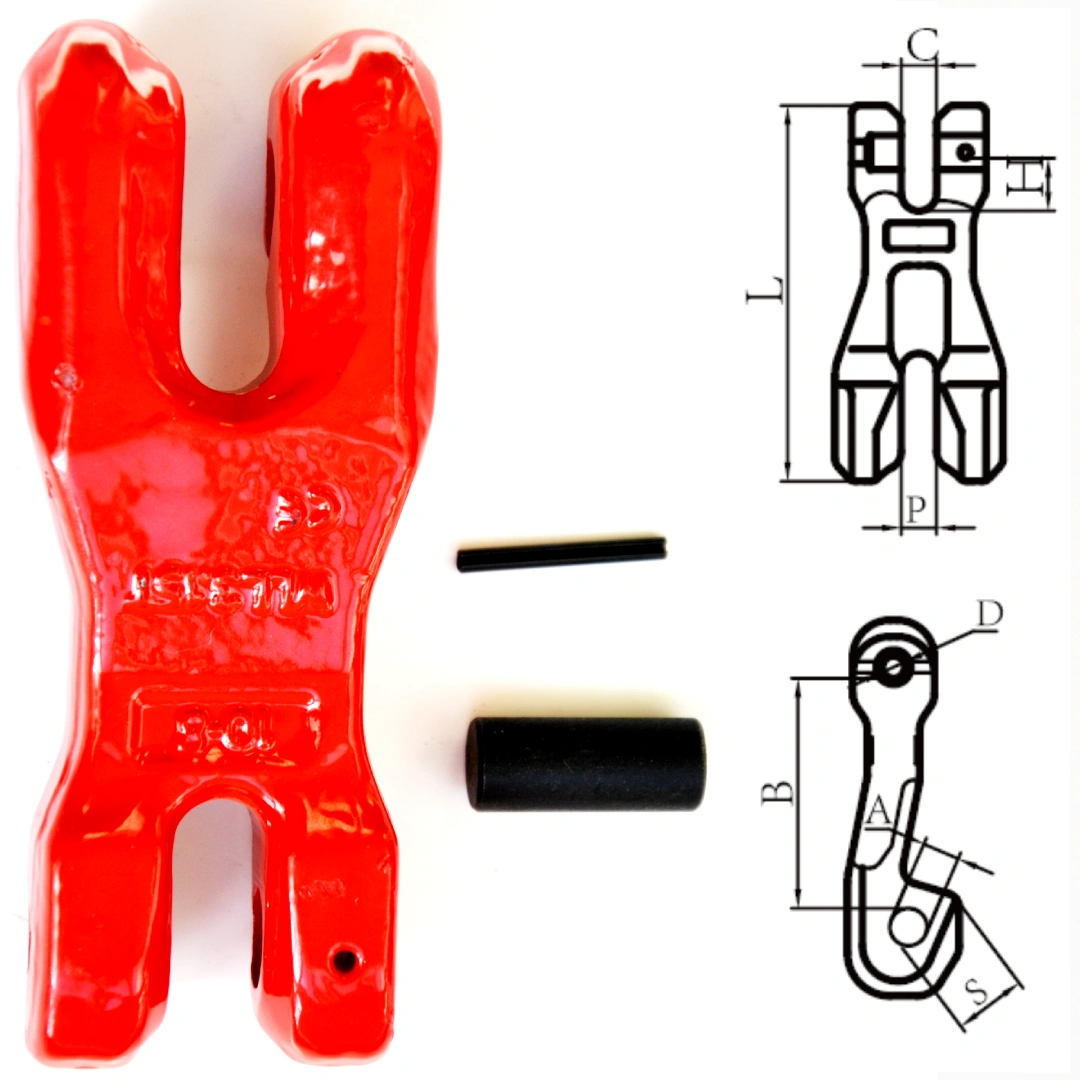

Products Diagrams

The clutch body, clevis pin, and interior surfaces cleanly machined—highlighting smooth curves and load-bearing geometry.

Reveals underside clevis jaw, forged steel contours, pin seating, and weld-free clean lines for strength and fit.

Material Specification

Grade:

Manufactured using Grade 80 alloy steel, heat-treated and quenched, providing high tensile strength and safety factor for lifting & rigging usage in heavy loads.

Finish:

Surface treated with corrosion-resistant powder coating (or optional galvanizing), ensuring durability in harsh outdoor or marine environments plus visibility for inspection.

Attachment:

Clevis clutch attaches directly to chain sling leg; clevis pin secures chain link, allowing adjustment without weakening working load limit.

Hook Type:

Not a hook itself but works with chain sling hooks. Clevis design supports use with grab, safety, or eye hooks for versatile rigging.

Material:

Forged high-alloy steel with strict material traceability; often EN 1677 / similar international standards compliance; fully inspected for cracks, hardness, toughness.

Application

Construction Industry

Used in scaffolding or lifting of beams, concrete forms; lets site operators shorten chain slings quickly to adapt length safely for diverse lifts.

Marine & Offshore

For rigging, mooring, and deck hardware; reliable chemical and saltwater resistance ensures clutch maintains working capacity even under corrosive maritime conditions.

Mining Industry

Applied to heavy-duty ore, rock or machinery hauling chains; withstands dynamic loads, abrasion, high drop impact, supporting safety in hazardous environments.

Advantages

Corrosion & Finish Protection

Our G80 Clevis Clutch uses premium finish (powder coat or optional galvanizing) that resists rust and abrasion far beyond standard painted units. That means longer life in wet, salty, corrosive environments—less downtime, less replacement cost.

Customization & Traceability

As direct manufacturer, we deliver custom chain-size matching, branded markings, special packaging. Every unit traceable with material certificates and test reports—wholesalers get confidence and consistency rival competitors.

Load Control & Durability

Forged and heat treated to strict Grade 80 standards with proof load and safety factor ~4× WLL. Keeps full working load even when shortening chain, unlike weaker clutches or makeshift fixes.

Bulk Capacity & Lead Time

We run advanced forging, machining, and QC lines. High capacity allows fast bulk order fulfillment without sacrificing quality. Large-volume clients experience shorter wait and reliable supply.

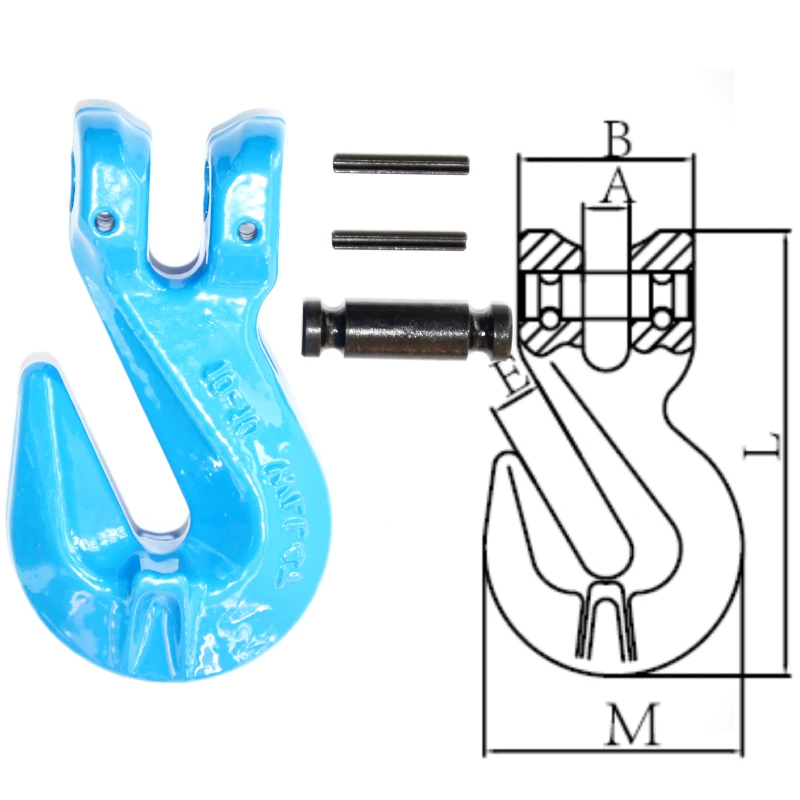

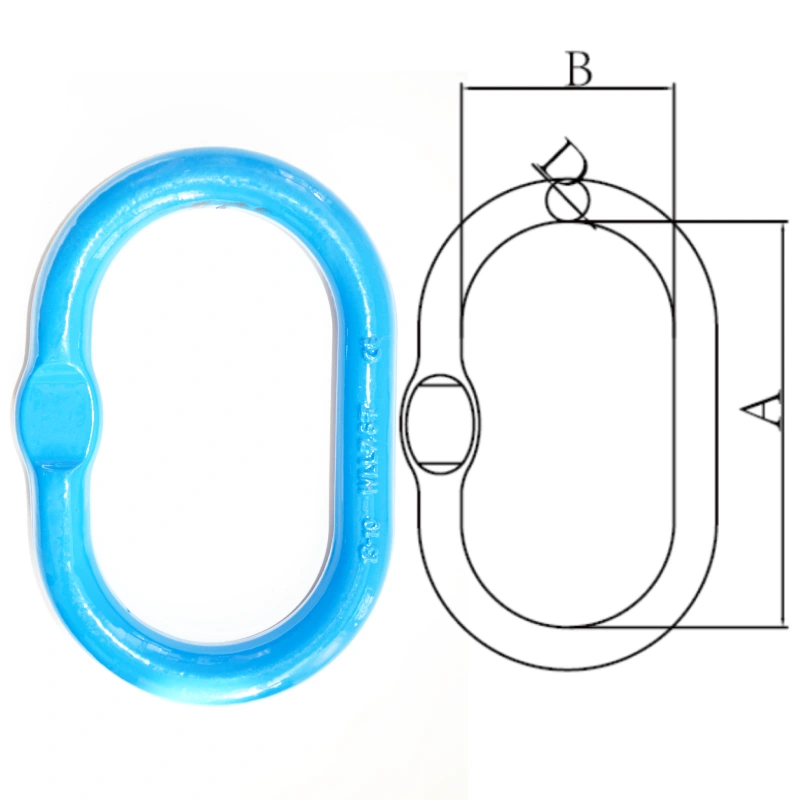

Supporting Products

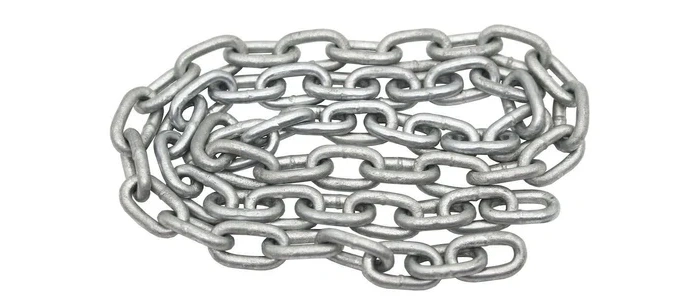

Grade 80 Alloy Chain

Heavy-duty chain legs to pair with clevis clutch, matching load capacity and safety standards.

Steel Wire Rope Sling / Cable

Used when flexible lifting needed, in combination with clevis clutch for shorter reach or custom rigging setups.

Shackles & Hooks

Forged shackles or hooks for connecting chain ends, allowing safe attachment to lifting points or other hardware.

FAQ

What does “G80 Clevis Clutch” mean?

“G80” refers to Grade 80 alloy steel standard used in rigging hardware, meaning high tensile strength and reliability. “Clevis Clutch” is a device that allows adjustment (shortening) of a chain sling leg through a clevis pin mechanism without reducing the working load limit.

Can I adjust chain length with the clevis clutch safely?

Yes. Designed for shortening chain slings safely. When installed correctly with matching chain size and within rated Working Load Limit (WLL), it lets you adjust length while retaining full strength, if used as per manufacturer’s instructions and standards like EN 1677.

How do I choose correct size of G80 Clevis Clutch?

Match the chain diameter, working load limit, and dimensions (A, B, C etc.) to your rigging chain. Always check manufacturer’s spec plate or datasheet. Undersizing weakens performance; oversizing may be inefficient or bulky.

Is the safety factor acceptable?

Yes. Most G80 Clevis Clutches give safety factor around 4:1 (ratio of breaking load to working load) per industry standard EN 1677, meaning they are tested to 4× their working load. Always check markings and test data.

Does finish matter and how to prevent corrosion?

Finish like powder coating or galvanization protects against rust, especially in outdoor or marine settings. Inspect periodically. If coating is damaged, re-touch or clean and protect to maintain safety and lifespan.

What makes your manufacturing process trustable?

As the direct manufacturer, we control all phases: raw material sourcing, alloy steel Grade 80 forging, heat treatment, crack detection, proof load testing. We issue certificates so you know strength and safety are verified.

What is your bulk order lead time?

For standard sizes, lead time is typically short (weeks). For large custom orders, we plan production schedules in advance and can expedite for urgent needs. We keep inventory and use efficient logistics to serve wholesalers globally.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.