Product Specifications

| G80 U.S. TYPE A-342 FORGED MASTER LINK | ||||||||

| SIZE | CHAIN SIZE | 1 LEG | 2 LEG | FOR WOPE | A | B | D | WEIGHT |

| IN. | IN. | WLL(TON) | WLL(TON) | WLL(TON) | MM | MM | MM | KG/PC |

| 1/2″ | 1/4″ | 1.5 | 2.12 | 3.4 | 127 | 63.5 | 13 | 0.36 |

| 5/16″ | 2 | 2.8 | ||||||

| 5/8″ | 5/16″ | 2 | 2.8 | 4 | 152 | 76 | 16 | 0.7 |

| 3/8″ | 3.15 | — | ||||||

| 3/4″ | 3/8″ | 3.15 | 4.25 | 5.6 | 140 | 70 | 19 | 0.93 |

| 7/8″ | 3/8″ | 3.15 | 4.25 | 6.9 | 160 | 90 | 22 | 1.5 |

| 1/2″ | 5.3 | — | ||||||

| 1″ | 1/2″ | 5.3 | 7.5 | 11.8 | 178 | 89 | 25 | 2.1 |

| 5/8″ | 8 | 11.2 | ||||||

| 1-1/4″ | 5/8″ | 8 | 11.2 | 17.7 | 222 | 111 | 32 | 4.24 |

| 3/4″ | 11.2 | 16 | ||||||

| 1-1/2″ | 3/4″ | 11.2 | 16 | 27.7 | 267 | 135 | 38 | 7.17 |

| 7/8″ | 15 | 21.2 | ||||||

| 1-3/4″ | 7/8″ | 15 | 21.2 | 38.5 | 305 | 152 | 45 | 11.55 |

| 1″ | 21.2 | — | ||||||

| 2″ | 1″ | 21.2 | 30 | 46.5 | 355 | 178 | 51 | 17.2 |

| 1-1/4″ | 31.5 | — | ||||||

| 2-1/4″ | 1-1/4″ | 31.5 | 45 | 64.9 | 406 | 203 | 57 | 24.5 |

| 2-1/2″ | — | — | — | 72.6 | 406 | 241 | 63.5 | 30.9 |

| 2-3/4″ | — | — | — | 98.4 | 406 | 228 | 70 | 39.5 |

| 3″ | — | — | — | 103 | 457 | 254 | 76 | 50.34 |

| 3-1/4″ | — | — | — | 119 | 508 | 305 | 82.5 | 65.68 |

| 3-1/2″ | — | — | — | 126 | 508 | 305 | 89 | 90.24 |

| 3-3/4″ | — | — | — | 152 | 508 | 254 | 95 | 89.27 |

| 4″ | — | — | — | 169 | 508 | 254 | 102 | 103.43 |

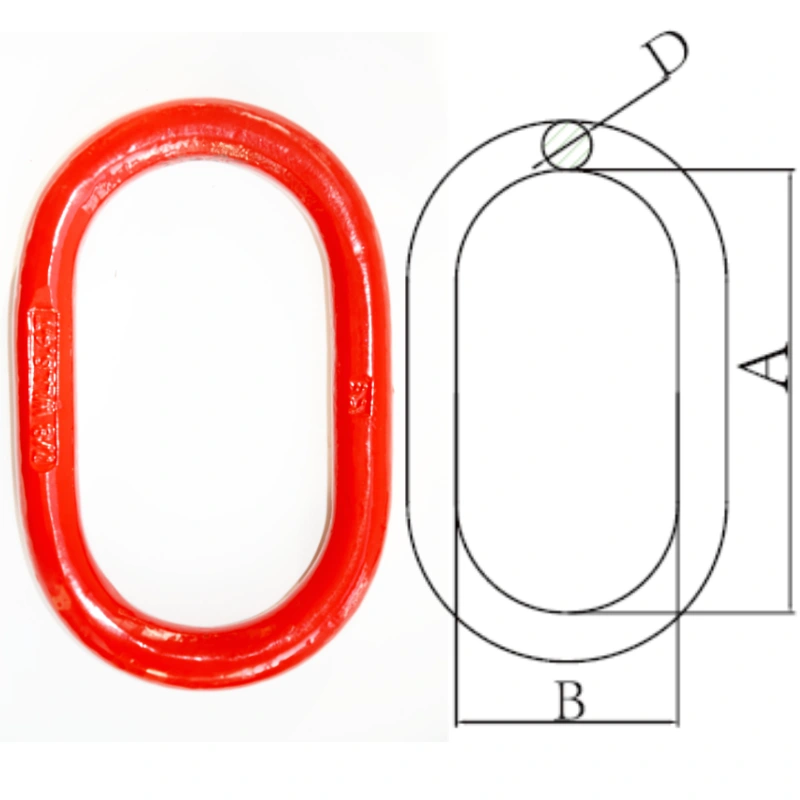

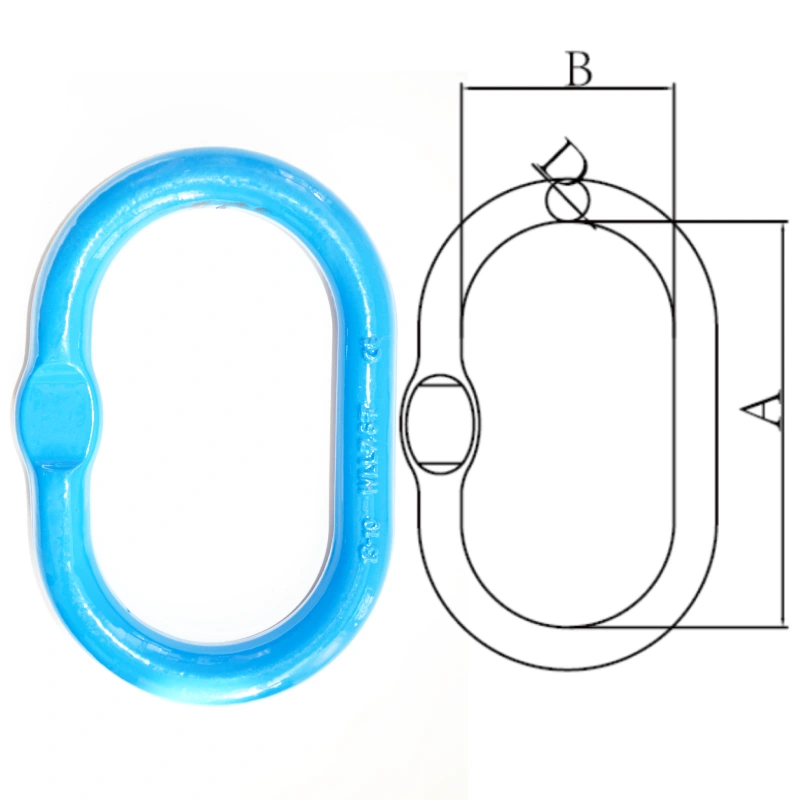

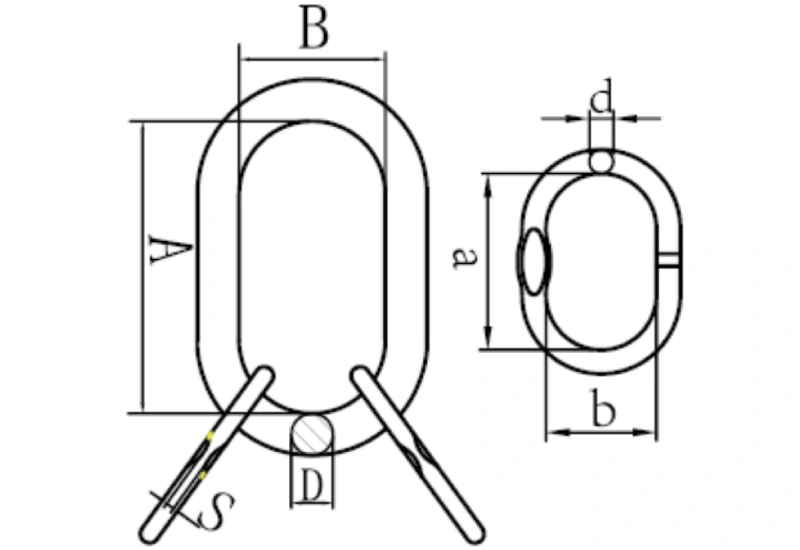

Products Diagrams

The G80 U.S. Type A-342 Forged Master Link shows its wide internal design, allowing multiple sling legs to fit securely. This shape ensures equal load distribution, minimizes stress points, and enhances safety during heavy lifting operations in demanding environments.

From the side, the link’s forged steel construction and consistent thickness become clear. The precision forging ensures durability, resistance against deformation, and long service life. Buyers can trust its uniform build for overhead lifting and repeated industrial use.

Material Specification

Grade:

Manufactured from Grade 80 alloy steel, designed for superior strength, load-bearing performance, and compliance with international lifting standards.

Finish:

Protected with a durable powder coating, offering excellent resistance to corrosion, wear, and harsh environmental conditions, ensuring longer service life.

Attachment:

Easily connects to cranes, hoists, chains, and slings, allowing direct or shackle-assisted attachment for flexibility across multiple rigging setups.

Hook Type:

Optimized for single or multi-leg sling use, the wide body design ensures stable load spacing, making lifting more controlled and secure.

Material:

Crafted from high-grade alloy steel, precision-forged for durability, safety, and reliability in demanding lifting applications across industries.

Application

Construction Industry

Used in lifting prefabricated concrete, beams, and structural steel, ensuring efficiency and safety in heavy-duty construction sites.

Marine & Offshore

Provides secure lifting and rigging for ships, cargo handling, and offshore platforms, withstanding challenging saltwater conditions.

Mining Industry

Handles oversized equipment, rock loads, and mining machinery with strength and safety, reducing downtime in tough environments.

Advantages

Corrosion & Finish Protection

Durable finish prevents rust, guaranteeing longer lifespan and reduced maintenance costs for buyers in tough conditions.

Customization & Traceability

Available in standard or tailored sizes, with full traceability and markings, offering peace of mind to bulk buyers.

Load Control & Durability

Forged strength ensures safe, stable load control, meeting the highest industry requirements for reliability and long service.

Bulk Capacity & Lead Time

Large production capacity ensures steady supply, while short lead times help distributors and wholesalers meet urgent demand.

Supporting Products

G80 Alloy Chain

Steel Wire Rope

High-strength wire ropes engineered for demanding construction, mining, and marine applications.

Pulleys & Sheaves

Precision pulleys for lifting systems, improving efficiency and reducing equipment strain.

FAQ

What makes the G80 U.S. Type A-342 Forged Master Link different from standard links?

This link is forged from Grade 80 alloy steel, offering higher strength and durability than standard links. It is designed specifically for overhead lifting and complies with international safety standards. The wide design also allows for better load spacing when using multi-leg slings.

Can you provide customized sizes or specifications for large orders?

Yes. As the manufacturer, we offer both standard sizes and customized options to fit your project requirements. We can adjust dimensions, finishes, and markings to meet distributor and brand-specific needs. Bulk orders also benefit from reduced lead times.

How do you ensure product quality and safety?

Each G80 U.S. Type A-342 Forged Master Link undergoes strict forging, heat treatment, and load testing processes. Our production complies with ISO and EN standards, ensuring traceability and certification. Quality checks guarantee safety, durability, and compliance for every order.

What industries commonly use this master link?

It is widely used in construction, marine & offshore, and mining industries. From lifting heavy concrete blocks to rigging offshore platforms and handling mining equipment, this link provides strength, reliability, and safety in demanding environments.

What is the lead time for bulk orders?

We maintain a large production capacity, allowing us to handle bulk orders quickly. Standard products are usually ready for dispatch within a short timeframe, while custom orders are fulfilled with efficient planning to minimize waiting times for distributors.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.