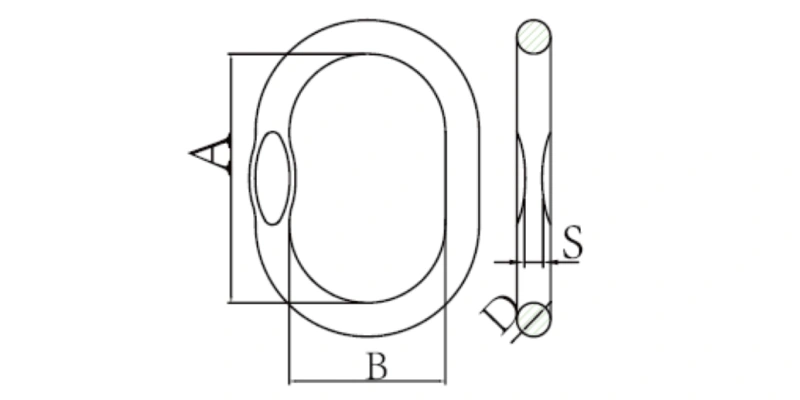

Product Specifications

| G80 U.S. TYPE A-344 WELDED MASTER LINK | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| SIZE (IN.) | WEIGHT (KG/PC) | A (MM) | B (MM) | D (MM) | S (MM) | CHAIN SIZE (IN.) | 1 LEG WLL (TON) | 2 LEG WLL (TON) | FOR WOPE WLL (TON) |

| 7/16″ | 0.27 | 100 | 60 | 12 | 6 | 1/4″ | 1.12 | 1.6 | 1.6 |

| 9/32″ | 1.5 | — | — | ||||||

| 1/2″ | 0.38 | 100 | 60 | 14 | 7.6 | 9/32″ | 1.5 | 2.12 | 2.5 |

| 5/16″ | 2 | — | — | ||||||

| 11/16″ | 0.85 | 160 | 90 | 18 | 8.4 | 5/16″ | 2 | 2.8 | 4 |

| 3/8″ | 3.15 | — | — | ||||||

| 3/4″ | 1.2 | 160 | 90 | 20 | 10.5 | 3/8″ | 3.15 | 4.25 | 6.5 |

| 1/2″ | 5.3 | — | — | ||||||

| 7/8″ | 1.63 | 180 | 100 | 22 | 13.5 | 1/2″ | 5.3 | 7.5 | 8 |

| 5/8″ | 8 | — | — | ||||||

| 1″ | 2.13 | 180 | 100 | 25 | 16.5 | 5/8″ | 8 | 11.2 | 11.5 |

| 3/4″ | 11.2 | — | — | ||||||

| 1-1/8″ | 3.81 | 270 | 140 | 28 | 19 | 3/4″ | 12.5 | — | 11.8 |

| 1-1/4″ | 5.05 | 270 | 140 | 32 | 19 | 3/4″ | 11.2 | 16 | 16 |

| 7/8″ | 15 | — | — | ||||||

| 1-3/8″ | 6.83 | 285 | 155 | 36 | 20 | 7/8″ | 15 | 21.2 | 24 |

| 1″ | 21.2 | — | — | ||||||

| 1-1/2″ | 8.9 | 300 | 160 | 40 | 26 | 1-1/8″ | 25 | — | 25 |

| 1-3/4″ | 12.8 | 340 | 180 | 45 | 26 | 1″ | 21.2 | 30 | 31.5 |

| 1-1/4″ | 31.5 | — | — | ||||||

| 2″ | 17.3 | 390 | 215 | 51 | 32 | 1-1/4″ | 31.5 | 45 | 45 |

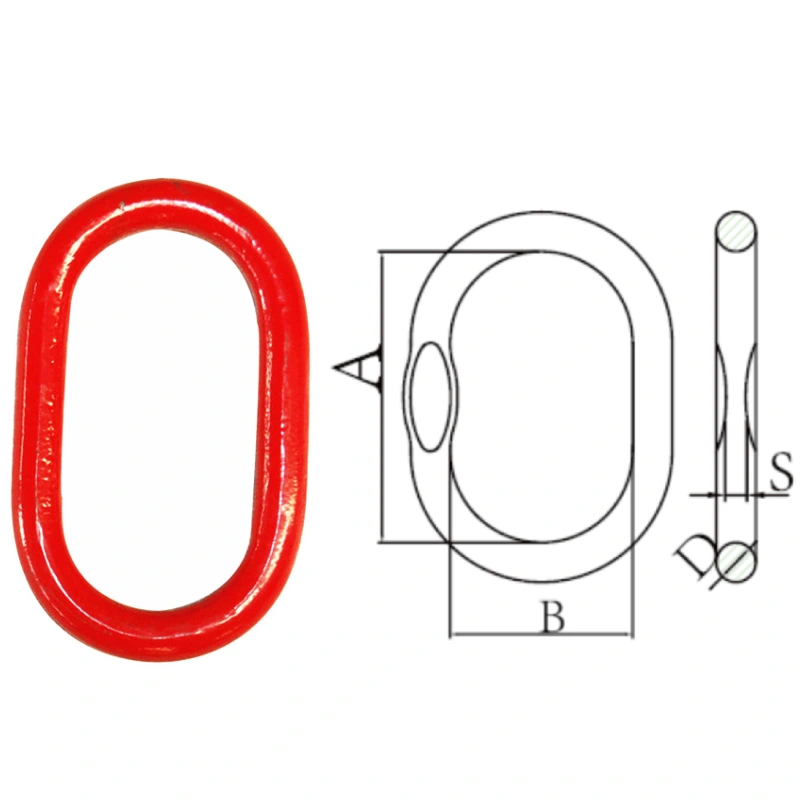

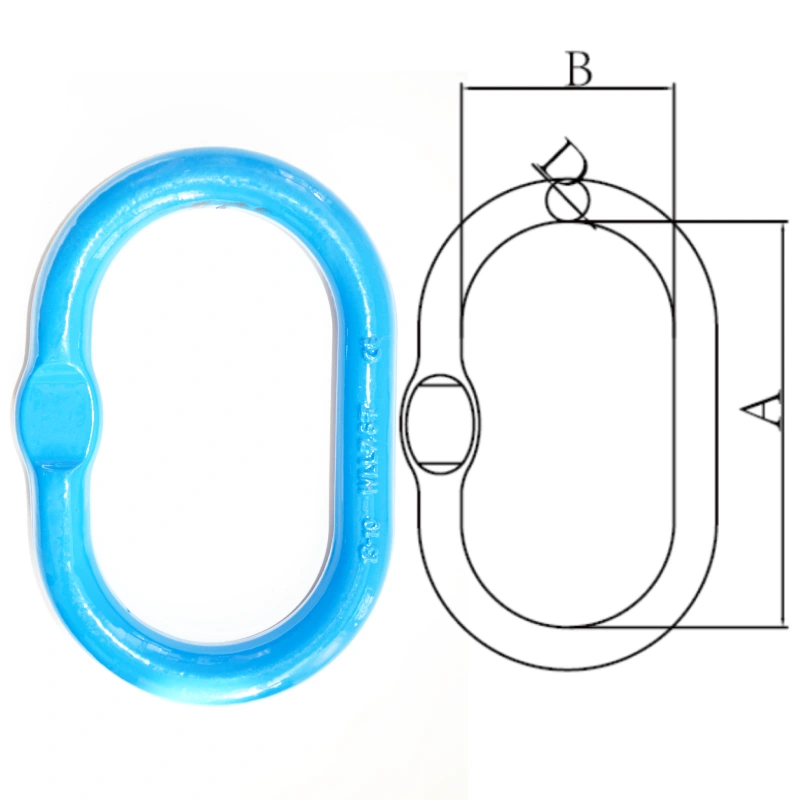

Products Diagrams

The G80 US Type A 344 Welded Master Link shows its wide opening. This design gives more room for attaching hooks, chains, and other sling hardware. It ensures easier handling and secure load balancing during lifting.

The welded construction and robust thickness of the link. Precision welding increases strength and reduces weak points. This ensures durability, long service life, and confidence in demanding lifting operations across construction, marine, and mining industries.

Material Specification

Grade:

Manufactured from Grade 80 alloy steel, meeting ASME B30.26 requirements for safety, strength, and ductility in lifting applications.

Finish:

Protected with a high-quality coating, giving resistance against corrosion, scratches, and harsh working conditions.

Attachment:

Designed to connect with cranes, hooks, slings, and rigging gear, offering flexible use in different lifting operations.

Hook Type:

Made for multi-leg sling connections, its larger inside width allows stable and secure load positioning.

Material:

Crafted from premium forged alloy steel, welded for extra durability and reliability in heavy-duty industrial use.

Application

Construction Industry

Used for lifting beams, panels, and structural materials safely and efficiently at construction sites.

Marine & Offshore

Handles cargo, offshore equipment, and rigging tasks with high reliability in saltwater environments.

Mining Industry

Supports safe lifting of machinery, rock loads, and mining components in extreme working conditions.

Advantages

Corrosion & Finish Protection

Coated finish protects against rust, reducing maintenance costs and extending service life.

Customization & Traceability

Available in standard and custom sizes, with full traceability for quality assurance

Load Control & Durability

Engineered for reliable strength, ensuring safe and steady lifting operations in demanding industries.

Bulk Capacity & Lead Time

High production capacity supports bulk orders, with fast lead times for distributors and wholesalers.

Supporting Products

Pulleys & Sheaves

Precision pulleys that enhance lifting efficiency and equipment performance.

FAQ

What standards does the G80 US Type A 344 Welded Master Link meet?

Our master link meets or exceeds ASME B30.26 requirements, covering identification, ductility, design factor, proof load, and temperature standards. Buyers can trust every piece is tested and certified for safe use in lifting applications.

Can I order customized sizes for specific projects?

Yes, we provide both standard and custom sizes. Whether you need specific dimensions for a multi-leg sling setup or a tailored finish for branding, we can produce according to your exact requirements.

How do you ensure product safety and quality?

Each master link undergoes strict welding, heat treatment, and proof load testing. We follow ISO and ASME guidelines, ensuring every product is traceable, durable, and compliant with global safety regulations.

What industries commonly use this master link?

It is widely used in construction, marine & offshore, and mining industries. From lifting beams and machinery to handling offshore equipment, it provides strength and dependability in heavy-duty operations.

What is the lead time for wholesale or bulk orders?

We maintain large production capacity and stock for fast delivery. Standard orders are fulfilled quickly, while customized orders are produced with short lead times to support distributors and project schedules.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.