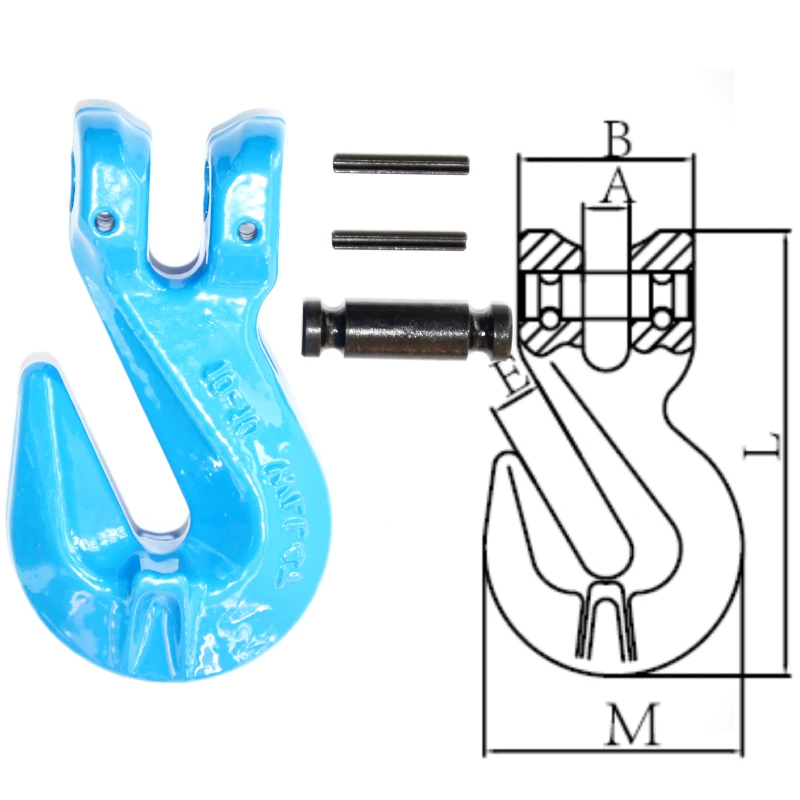

| G80 U.S. TYPE EYE GRAB HOOK | ||||||||

| SIZE | WEIGHT | WLL | B.L | DIMENSIONS(MM) | ||||

| IN. | KG/PC | TON | TON | E | D | H | K | L |

| 1/4″ | 0.13 | 1.2 | 4.8 | 8 | 13 | 19 | 54 | 81 |

| 9/32″ | 0.27 | 2 | 8 | 9.5 | 15 | 23 | 64 | 98 |

| 3/8″ | 0.55 | 3.2 | 12.8 | 12.5 | 20 | 30 | 82 | 125 |

| 1/2″ | 1.3 | 5.4 | 21.6 | 17 | 25 | 42 | 106 | 165 |

| 5/8″ | 2.48 | 8.2 | 32.8 | 20 | 30 | 49 | 127 | 196.5 |

| 3/4″ | 3.8 | 12.8 | 51.2 | 23 | 34.5 | 56 | 152 | 231.6 |

| 7/8″ | 5.8 | 15.5 | 62 | 28.6 | 40.5 | 65.5 | 175 | 267.6 |

Products Diagrams

Highlights the eye loop geometry and thick hook throat, showing how chain fits snugly without slipping, built for Grade 80 strength.

Internal grain flow of forged steel, heat-treatment zone and smooth finish, indicating toughness and resistance to fatigue.

Material Specification

Grade: Grade 80 alloy steel, quenched & tempered, meeting EN 1677-1 / ASTM standards for lifting hardware and chain components.

Finish: Durable zinc plating or powder coat finish, offering excellent corrosion protection and long service life in harsh conditions.

Attachment: Closed eye design for secure connection to master link, wire rope or chain assemblies; minimal movement ensures stability.

Hook Type: Grab-hook style with eye (closed) enables link grabbing for shortening or chain adjustment without extra fittings.

Material: Forged alloy steel with proof load 2.5× working load, magnetically crack-detected, quality assured and traceable.

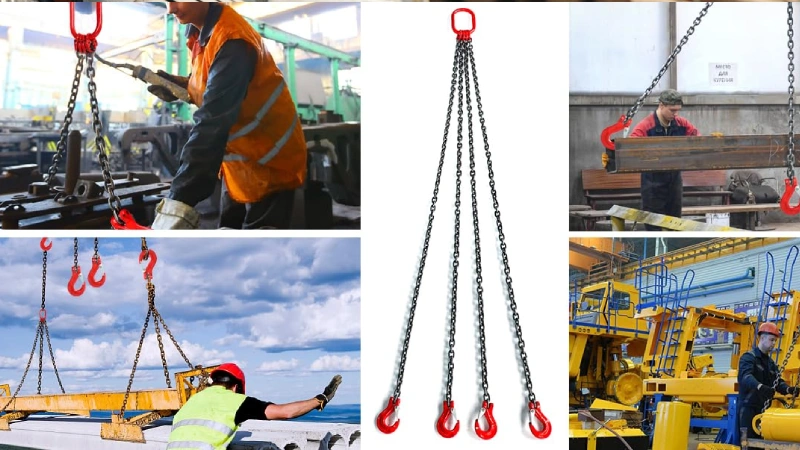

Application

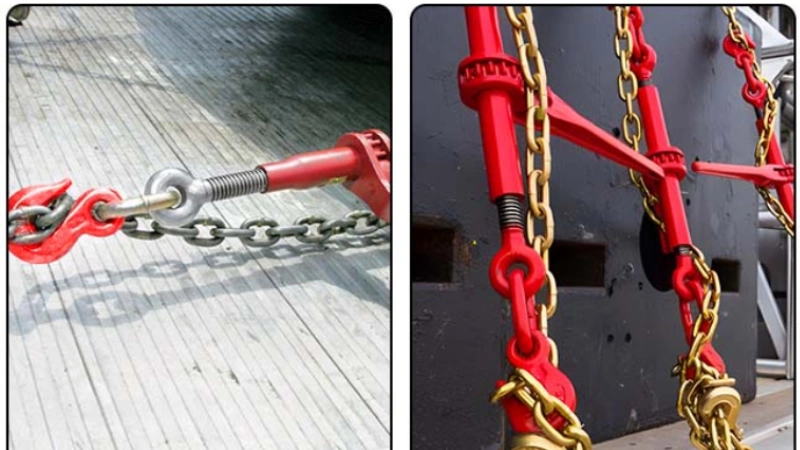

Transport & Logistics

Used to adjust and secure chains on flatbeds or trailers, preventing load shift by grabbing chain links precisely.

Construction & Rigging

Ideal for scaffolding, tie-downs, and lifting of building materials where chain slack must be managed.

Agriculture & Forestry

Helps manage logging chains, tractor attachments or towing gear; resists wear from dirt, moisture, and heavy use.

Advantages

Corrosion & Finish Protection

We apply zinc plating or durable powder coated finishes ensuring superior resistance to rust and abrasion.

Manufacturing Process

We are ISO 9001 certified, use EN/ASTM standard Grade 80 material, produce with 100% crack detection and proof load testing.

Load Control & Durability

Our G80 U.S. TYPE EYE GRAB HOOK has precise throat geometry, quenched alloy steel and proof-tested strength.

OEM & Fast Bulk Delivery

Because we control forging, heat treatment, finishing in-house, we offer custom sizes, private labeling, and faster lead times.

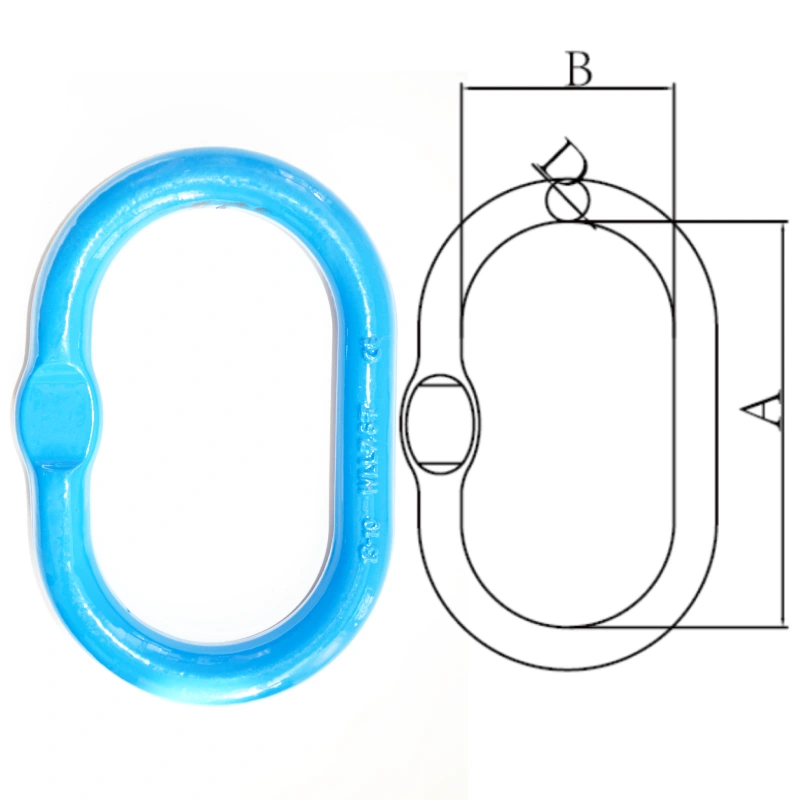

Supporting Products

Wire Rope Sling

Flexible steel rope sling, suitable for heavy lifting and rigging support.

Shackle (Bow / D-Shackle)

Connects hook to chains, ropes, or slings, offering secure linkage.

Turnbuckle

Adjusts tension in chain or rope systems, maintaining stability and load security.

FAQ

What working load limit (WLL) can I expect from a G80 Eye Grab Hook?

Working Load Limit depends on chain size; for example, a 3/8″ Grade 80 eye grab hook might have ~7,100 lbs WLL when used properly with matching chain. Always verify in product spec.

Is it safe to use eye grab hooks for overhead lifting?

Many safety standards reduce rated capacity by ~20% if used overhead. Some jurisdictions don’t allow grab hooks overhead. Always check local and product regulatory guidance.

How do I inspect eye grab hooks for safety before use?

Check for cracks, deformations, throat opening widening, eye wear, pins wear, surface corrosion. Replace if any damage; fatigue or cracks are dangerous in lifting situations.

What temperature and environmental limits exist for these hooks?

Alloy steel eye grab hooks perform well in many conditions, but extreme cold or heat may affect toughness; coatings help with corrosion. Consult manufacturer for extreme environments.

Can I use eye grab hook to shorten chain or adjust chain length safely?

Yes. The grab design allows chain link to be caught (“grabbed”) so that chain length can be adjusted without extra fitting. Use matching chain grade and correct hook size.

What quality checks does your factory perform on each batch?

We conduct magnetic crack detection (100%), proof load testing (often 2.5× WLL), dimensional checks, and heat treatment verification. Every batch has certificates traceable to raw material supplier.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.