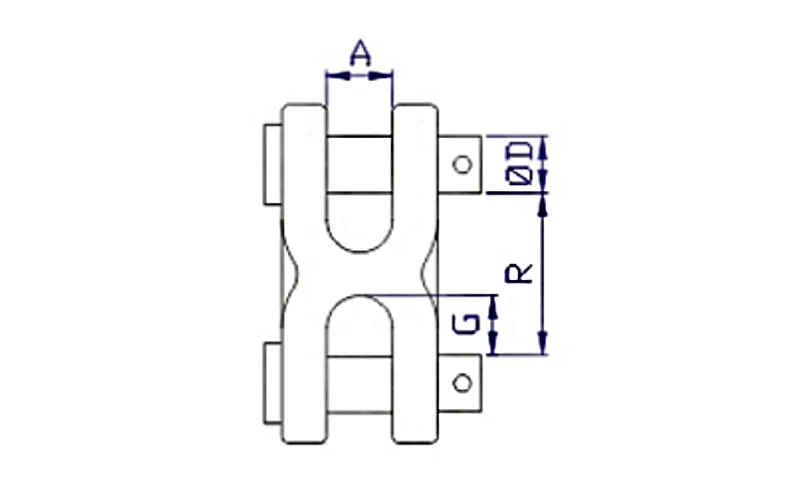

Product Specifications

| SIZE | WEIGHT | WLL | A | D | G | R |

| IN. | KG/PC | TON | MM | MM | MM | MM |

| 1/4″-5/16″ | 0.15 | 2 | 12 | 9.5 | 11.5 | 30.5 |

| 3/8″ | 0.2 | 3 | 13.9 | 12 | 12.6 | 34.4 |

| 7/16″-1/2″ | 0.45 | 5 | 17 | 14 | 16.6 | 45.5 |

| 5/8″ | 0.6 | 7.5 | 20 | 17.5 | 19.5 | 55 |

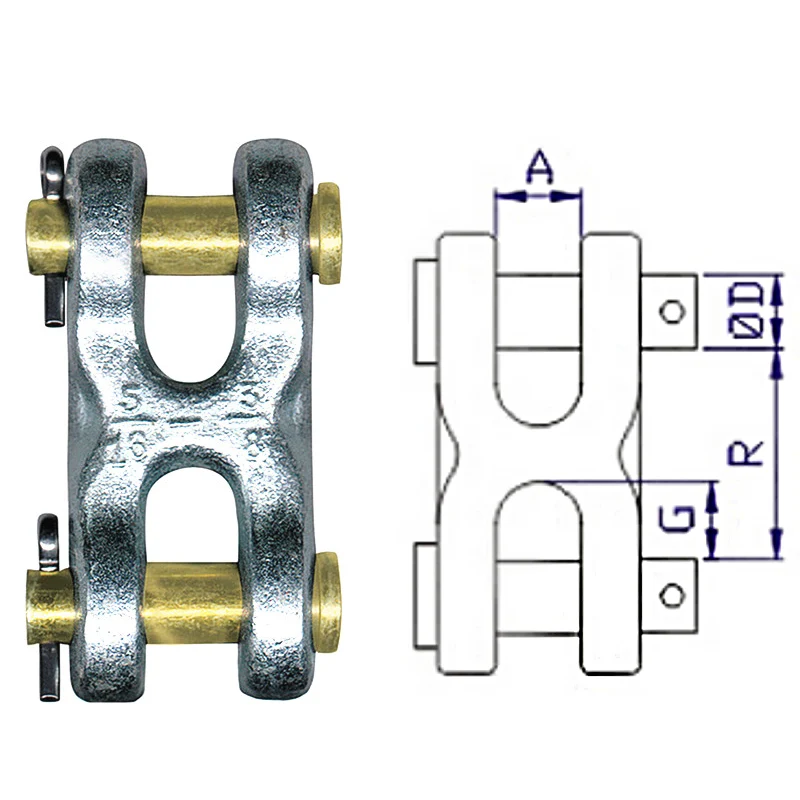

Products Diagrams

The H Type Twin Clevis Link features dual clevis ends for quick and reliable chain-to-chain or chain-to-hook connections. Its symmetrical design ensures balanced load distribution during towing or lifting operations.

Each H Type Twin Clevis Link is forged and machined to meet strict dimensional tolerances. The uniform gap and pin alignment allow smooth assembly with various chain sizes, enhancing operational efficiency.

Material Specification

Grade:

Manufactured from premium-grade carbon steel, ensuring high tensile strength and consistent mechanical performance under dynamic load conditions.

Finish:

Available in white zinc-plated, yellow zinc-plated, or hot-dip galvanized coating to provide long-term corrosion and rust protection in outdoor or marine use.

Attachment:

Designed for webbing straps, connecting chains, or tow assemblies, offering versatile linkage options for multiple load-bearing applications.

H Type Twin Clevis Link Type:

H-type twin design with dual clevis ends allows secure, symmetrical load connection and easy installation with standard chain fittings.

Material:

Forged carbon steel provides exceptional durability, wear resistance, and impact tolerance, making it ideal for industrial rigging and transportation applications.

Application

Construction Industry

Used for lifting, securing, and connecting heavy equipment or materials safely on job sites, providing dependable strength and load control.

Marine & Offshore

Ideal for connecting mooring chains and towing lines in saltwater environments, ensuring corrosion resistance and long-term reliability.

Mining Industry

Used to link heavy-duty haulage or conveyor chains, providing high fatigue strength and impact resistance in harsh mining operations.

Advantages

Corrosion & Finish Protection

Each link features superior zinc or galvanized coating to resist corrosion and abrasion, ensuring extended service life in tough environments.

Customization & Traceability

Available in customized sizes and finishes with batch traceability, ensuring quality control for OEM and bulk production needs.

Load Control & Durability

Engineered to withstand 4 times the working load limit, providing enhanced safety and long-term stability in critical lifting applications.

Bulk Capacity & Lead Time

We maintain large-scale production and fast lead times, enabling efficient global supply for distributors and industrial clients.

What Our Clients Say

FAQ

What is an H Type Twin Clevis Link used for?

It connects two chain ends or chain and hook assemblies securely. Its twin clevis design ensures balanced load transfer, making it ideal for towing, hoisting, and rigging applications.

How strong is the H Type Twin Clevis Link?

Each link is designed with an ultimate load that is four times the working load limit, ensuring high safety margins in heavy-duty applications.

Can the surface finish be customized?

Yes. We offer multiple finishes, including white zinc, yellow zinc, and hot-dip galvanized coatings. Custom coatings can also be applied to meet your environment’s needs.

What materials are available?

We primarily use forged carbon steel for superior strength and wear resistance. Stainless steel options are available upon request for marine-grade applications.

Do you provide OEM and ODM services?

Powerful Machinery supports OEM/ODM with customized sizes, finishes, and markings to match your brand and project requirements.

What is your production lead time for bulk orders?

Typically 25–35 days depending on order volume. Our large inventory and advanced forging facilities help ensure fast and reliable global supply.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.