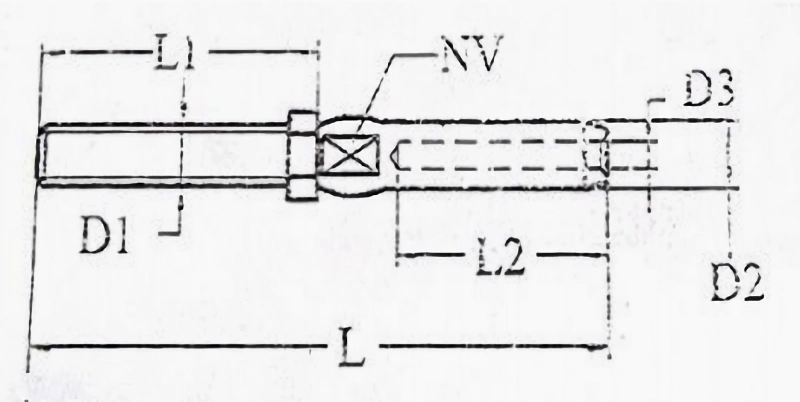

DIAGRAM

SPECIFICATIONS

| ITEM NO | WIREΦ | L | L1 | L2 | NV | D1 | D2±0.003″ | D3 | WT |

| in | in | in | in | in | in | in | in | KGS | |

| HF9297-A001/8 | 1/8″ | 3.87″ | 1.875″ | 1.45″ | 0.157″ | 1/4″-UNC | 0.218″ | 0.14″-0.145″ | 0.018 |

| HF9297-A03/16 | 3/16″ | 4.3″ | 1.93″ | 1.9″ | 0.236″ | 1/4″-UNC | 0.295″ | 0.201″-0.206″ | 0.025 |

| HF9297-A03/16 | 3/16″ | 4.68″ | 2.31″ | 1.9″ | 0.236″ | 5/16″-UNC | 0.295″ | 0.201″-0.206″ | |

| HF9297-A03/16 | 3/16″ | 5.31″ | 2.75″ | 2″ | 0.236″ | 3/8″-UNC | 14 | 0.201″-0.206″ | |

| HF9297-A001/4 | 1/4″ | 5.5″ | 2.31″ | 2.52″ | 0.315″ | 5/16″-UNC | 0.425″ | 0.265″-0.27″ | 0.057 |

PRODUCT FEATURES

-

Constructed from AISI 316 marine-grade stainless steel

-

Corrosion-resistant and durable in harsh marine and coastal conditions

-

UNC threaded for secure attachment

-

Not suitable for roll swaging machines, intended for hand swaging

-

Ideal for applications exposed to temperature fluctuations and alkaline moisture

INSTRUCTIONS & CAUTIONS

Ensure Correct Swaging Tools are Used

When installing the hand swage threaded stud, it’s crucial to use the right swaging tools. These studs are specifically designed for hand swaging, not roll swaging machines. Using the correct tool ensures the stud is properly secured, preventing slippage or weak connections. If you need guidance on swaging techniques, don’t hesitate to contact our team for detailed instructions.

Regularly Inspect for Wear and Corrosion

Stainless steel hand swage threaded studs are built for durability, but regular inspection is key to maintaining their performance. Look for signs of corrosion or wear, especially in marine or outdoor environments where exposure to salt and moisture is high. By checking regularly, you can identify potential issues before they affect your rigging system, ensuring safe and efficient use.

Avoid Overloading the System

Always ensure that the hand swage threaded stud is used within its rated load capacity. Overloading can cause stress and lead to premature failure. Take into account the working environment, including temperature changes, and make sure you’re using the stud that’s right for your application. If you’re unsure about load ratings, we’re happy to assist with recommendations tailored to your project.

Ensure Proper Thread Engagement

When attaching components to the threaded stud, make sure the threads are fully engaged and secure. Loose connections can lead to system failure. Tighten threaded connections carefully to avoid damaging the threads or compromising the integrity of the system. If you need support with proper installation, feel free to reach out to our team for expert advice.

Note: Need more help with installation or technical support? Contact us today for a personalized tutorial on the correct use and installation of our hand swage threaded studs.

OUR ADVANTAGES

Personalized Customer Support

At Powerful Machinery, we treat every customer like a partner. Our team provides tailored advice, helping you choose the right products and offering custom solutions based on your unique needs. Whether you're dealing with a tricky project or need specific details, we’re here to guide you every step of the way, making sure you get exactly what you need.

Competitive Pricing with Bulk Discounts

At Powerful Machinery, we understand the importance of cost-effectiveness. That’s why we offer competitive pricing on all our products, with additional discounts for bulk orders. We’re committed to providing top-quality rigging hardware at prices that help you maintain healthy margins, all while ensuring you don’t compromise on performance or durability.

Expert Guidance Throughout the Process

We don’t just sell products; we build lasting relationships. From initial inquiries to post-purchase support, our knowledgeable team is here to provide expert guidance. Whether it’s installation advice, troubleshooting, or product recommendations, we make sure you get the right support at every stage of your purchase, helping you save time and avoid costly mistakes.

Fast and Reliable Delivery

We understand that time is critical for wholesalers and large markets. That's why we focus on fast, dependable shipping. No matter the size of your order, we ensure timely delivery to keep your projects on schedule. Our team works efficiently to meet deadlines, giving you the confidence to plan ahead and avoid unnecessary delays.

OUR REVIEWS

FAQ

What is the difference between hand swage and roll swage threaded studs?

Hand swage threaded studs are designed to be manually installed using swaging tools, whereas roll swage studs require a roll swaging machine. Hand swage studs are ideal for smaller installations or custom work, while roll swage studs are used for mass production in high-volume applications. Choosing the right type depends on your project’s size and complexity.

How long does it take to receive a bulk order of hand swage threaded studs?

Bulk orders of hand swage threaded studs typically take between 10-15 business days for delivery, depending on the order size and customization requirements. We offer fast shipping, so if you need a more urgent order, let us know, and we’ll prioritize it. We also provide tracking information once the order is shipped for your convenience.

Can I order hand swage threaded studs in bulk for large projects?

Yes, we offer bulk ordering for large projects. Our sales team will work with you to determine the exact quantity and any customization needed. We offer competitive pricing and volume discounts to ensure you get the best value for your large-scale needs. Reach out to us for a quote, and we’ll provide all the details for your order.

Do you offer any technical support for installation?

Absolutely! We provide technical support for the installation of our stainless steel hand swage threaded studs. If you need assistance with proper installation or have any questions about the product, our team is available to guide you. Just contact us, and we’ll provide the help you need to ensure your system is set up correctly.

Are your hand swage threaded studs compatible with other rigging hardware?

Yes, our hand swage threaded studs are designed to be compatible with most other rigging hardware. Whether you’re working with wire ropes, turnbuckles, or other components, our studs are made to work seamlessly within a comprehensive rigging system. If you need specific compatibility details, feel free to contact us, and we’ll assist with your setup.

What certifications do your hand swage threaded studs have?

Our stainless steel hand swage threaded studs meet industry standards and certifications, including ISO:9001:2008. We ensure that our products undergo strict quality control processes to guarantee performance and reliability. If you need additional certifications or documentation for your project, just let us know, and we’ll provide them.

Can I track my order once it’s placed?

Yes, once your order is processed and shipped, you’ll receive a tracking number to monitor the progress of your delivery. We ensure timely and secure shipping, and you can easily follow your order until it reaches your location. If there are any issues with your order, our customer support team is always available to assist.