DIAGRAM

SPECIFICATIONS

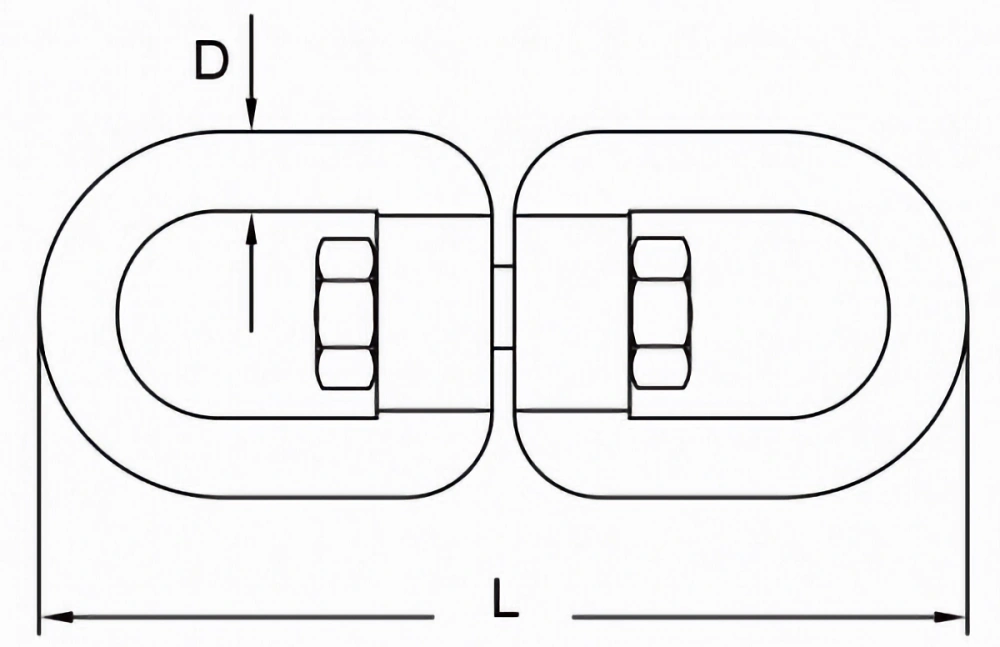

| ITEM NO | D | L | H | A | WLL | WT |

| mm | mm | mm | mm | mm | tons | |

| HF0037-A/B0005 | 5 | 60 | 11.5 | 10 | 0.1 | 0.041 |

| HF0037-A/B0006 | 6 | 66 | 12 | 12 | 0.15 | 0.058 |

| HF0037-A/B0008 | 8 | 94 | 16 | 16 | 0.3 | 0.145 |

| HF0037-A/B0010 | 10 | 118 | 22 | 20 | 0.5 | 0.275 |

| HF0037-A/B0013 | 13 | 152 | 28 | 26 | 1 | 0.684 |

| HF0037-A/B0016 | 16 | 188 | 37 | 32 | 1.5 | 1.12 |

| HF0037-A/B0019 | 19 | 229 | 44 | 38 | 2 | 2.21 |

PRODUCT FEATURES

- Material: 316 Stainless Steel for enhanced corrosion resistance

- Design: Jaw and jaw connections with a secure screw pin

- Applications: Ideal for marine, rigging, and heavy-duty industrial use

- Finish: High-polished for a sleek, durable surface

- Functionality: Prevents twisting and knotting of ropes and chains

INSTRUCTIONS & CAUTIONS

Verify Load Capacity Before Use

Always check the load rating of the stainless steel jaw & jaw swivel to ensure it matches the weight of your load. Using a swivel with a load capacity that’s too low can lead to failure, which is dangerous. It’s essential to match the swivel’s strength with the demands of your rigging system to prevent accidents and ensure safe operations.

Inspect for Damage Regularly

Before each use, inspect the jaw & jaw swivel for signs of wear, corrosion, or damage. Pay close attention to the screw pin and the jaws to make sure they’re intact and secure. Any signs of wear should prompt immediate replacement of the swivel to avoid the risk of malfunction or failure during operation.

Ensure Proper Installation

When installing the jaw & jaw swivel, ensure both ends are securely attached to your rigging components. The jaw should fit tightly to shackles or chains, while the eye end should be properly aligned with hooks or ropes. Improper installation can cause uneven load distribution or failure during use, so always follow the manufacturer’s instructions.

Avoid Over-Tightening the Pin

It’s important not to over-tighten the screw pin when attaching the swivel. Over-tightening can restrict the swivel’s rotation, causing excessive wear or even damaging the product. Tighten the pin just enough to secure the swivel, allowing it to rotate freely and perform as intended without undue stress.

OUR ADVANTAGES

Customization for Your Needs

Unlike many competitors, Powerful Machinery offers fully customizable jaw & jaw swivels. Whether you need a specific load capacity or unique dimensions for your rigging setup, we tailor each swivel to your exact specifications. This means you get the right product for your job, avoiding delays and inefficiencies with generic solutions.

Expert Support Every Step of the Way

When you choose Powerful Machinery, you’re not just buying a product—you’re getting expert support. Our team is available to help with product selection, technical questions, and even installation advice. We’re dedicated to ensuring you get the most out of your jaw & jaw swivels, providing guidance and troubleshooting whenever you need it.

Durable, Long-Lasting Quality

Powerful Machinery’s jaw & jaw swivels are made from high-grade 316 stainless steel, ensuring maximum durability and corrosion resistance. We stand behind the quality of our products, offering long-lasting performance even in harsh environments. You won’t have to worry about frequent replacements, saving you time and money in the long run.

Fast Delivery & Reliable Service

We understand time is critical in your projects. That’s why we ensure quick turnaround times and reliable delivery. Whether you’re ordering a single unit or bulk quantities, Powerful Machinery keeps your schedule on track with prompt shipping and timely updates, minimizing downtime and keeping your operations running smoothly.

OUR REVIEWS

FAQ

How do I choose the right size jaw and jaw swivel for my project?

-

Match Load Capacity: Ensure the swivel’s load capacity aligns with the weight of the load you plan to lift or move.

-

Check Jaw Compatibility: Verify that the jaw fits securely with your shackles or chains to ensure a safe connection.

-

Eye End Compatibility: Make sure the eye end of the swivel is compatible with your hooks or ropes for smooth rigging.

-

Need Assistance? If you’re unsure about the sizing, our team is available to help you select the perfect jaw and jaw swivel based on your project’s requirements.

What are the benefits of using stainless steel jaw and jaw swivels over galvanized swivels?

Stainless steel jaw and jaw swivels, particularly those made with AISI 316 stainless steel, outperform galvanized swivels in terms of corrosion resistance, especially in saltwater and chemical environments. Stainless steel offers superior durability, preventing rust and degradation over time. This means fewer replacements and less maintenance, making it a more cost-effective choice in the long run.

What load capacities are available for stainless steel jaw and jaw swivels?

Stainless steel jaw and jaw swivels come in a variety of load capacities to suit different applications. Depending on your project’s needs, you can choose swivels with light, medium, or heavy-duty load ratings. Always ensure the swivel you select matches or exceeds the weight of the load you plan to lift. Our team can help you determine the appropriate load capacity based on your specific requirements.

What is the difference between jaw & jaw swivels and eye & eye swivels?

Jaw & jaw swivels feature a U-shaped jaw on both ends, allowing for a more secure connection with shackles or chains. This design is often used in heavy-duty applications where a fixed, secure attachment is necessary. On the other hand, eye & eye swivels have circular eyes at both ends and are typically used for applications requiring more flexibility, like connecting with hooks or ropes. Both offer rotating capabilities but are suited for different rigging needs.

How do I place an order for stainless steel jaw and jaw swivels?

-

Select Size & Load Capacity: Choose the appropriate size and load capacity from our catalog based on your project’s needs.

-

Customization Options: Contact us if you require custom sizes or specifications for your swivels.

-

Order Directly Online: Place your order easily through our website for a smooth transaction.

-

Contact Sales Team: Reach out to our sales team for further assistance or to discuss your project’s specific requirements.

-

Fast & Reliable Delivery: Once your order is confirmed, we ensure quick and reliable delivery to meet your deadlines.