DIAGRAM

SPECIFICATIONS

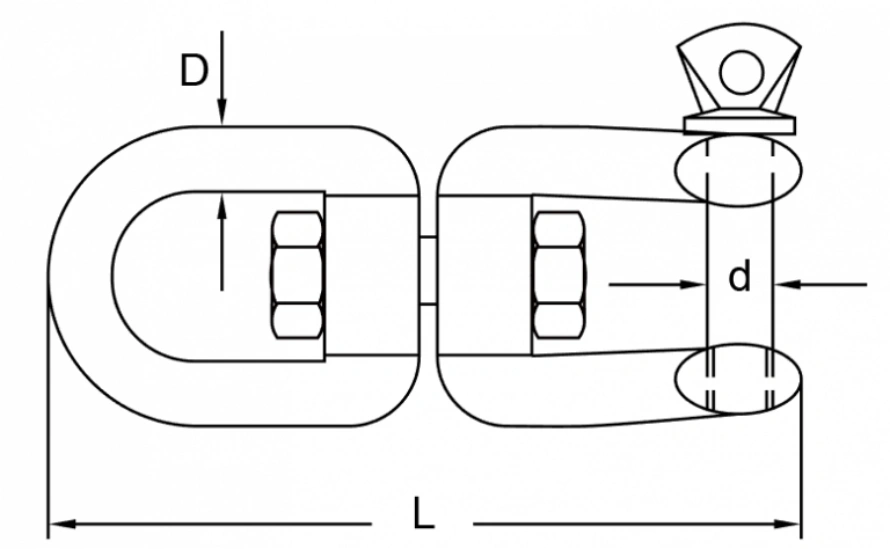

| ITEM NO | d | L | H | B | A | WT |

| mm | mm | mm | mm | mm | KGS | |

| HF0036-A/B0005 | 5 | 60 | 11.5 | 13 | 10 | 0.039 |

| HF0036-A/B0006 | 6 | 66 | 12 | 15 | 12 | 0.054 |

| HF0036-A/B0008 | 8 | 92 | 16 | 20 | 16 | 0.133 |

| HF0036-A/B0010 | 10 | 118 | 22 | 24 | 20 | 0.253 |

| HF0036-A/B0013 | 13 | 152 | 28 | 32 | 26 | 0.615 |

| HF0036-A/B0016 | 16 | 188 | 37 | 39 | 32 | 1.03 |

| HF0036-A/B0019 | 19 | 229 | 44 | 41 | 38 | 2.07 |

PRODUCT FEATURES

- Material: Type 316 Stainless Steel for maximum corrosion resistance

- Design: U-shaped jaw and circular eye for versatile rigging

- Durability: High-strength and long-lasting in harsh environments

- Applications: Ideal for marine, industrial, and heavy-duty use

- Customization: Available in standard and custom sizes

INSTRUCTIONS & CAUTIONS

Check Load Limits

Always verify the load capacity of the stainless steel jaw eye swivel before use. Ensure that the weight of your load doesn’t exceed the swivel’s rating. Overloading can cause failure, leading to accidents and costly repairs. It’s essential to match the swivel’s capacity to your specific rigging needs to maintain a safe and efficient setup.

Regular Inspections

Before every use, inspect the jaw eye swivel for signs of wear, corrosion, or damage. Pay close attention to the jaw fitting, pin, and the eye for any deformation. If any parts appear compromised, replace the swivel immediately. Routine inspections will keep your rigging system running smoothly and prevent failures when you need it most.

Proper Installation

Ensure the swivel is properly installed with secure attachments. The jaw end should be firmly connected to shackles or chains, while the eye end must be aligned with the rigging system for smooth rotation. Incorrect installation can lead to poor performance or malfunction, compromising both safety and efficiency.

Avoid Over-Tightening

When attaching the jaw eye swivel to your rigging setup, avoid over-tightening the components. Too much force can damage the swivel or restrict its movement. Make sure it’s secure, but allow enough space for smooth rotation. This will help prevent stress on the swivel, ensuring long-lasting durability and safe operation.

OUR ADVANTAGES

Customization to Fit Your Needs

Unlike other manufacturers, Powerful Machinery offers custom sizes and specifications for our stainless steel jaw eye swivels. Whether you need a particular load capacity or specific dimensions, we work closely with you to deliver a product tailored to your exact rigging requirements. This level of customization helps you avoid delays and ensures your projects are completed efficiently.

Expert Support & Guidance

At Powerful Machinery, we don’t just sell products—we offer expert advice. Our team is available to answer questions, assist with product selection, and offer troubleshooting support whenever needed. We pride ourselves on providing the best customer experience, helping you make the right choice for your rigging system and ensuring smooth operations.

High-Quality, Long-Lasting Performance

We stand behind the durability of our stainless steel jaw eye swivels. Made from high-quality AISI 316 stainless steel, our swivels are designed for long-term use in harsh environments like marine and industrial settings. You’ll get reliable performance and corrosion resistance, which means fewer replacements and lower overall costs for your business.

Fast Turnaround & Reliable Delivery

We understand that time is critical in rigging and lifting applications. That’s why we prioritize quick turnaround times and reliable delivery schedules. Whether you place a small or large order, you can count on Powerful Machinery to deliver your stainless steel jaw eye swivels on time, minimizing downtime and keeping your projects on track.

OUR REVIEWS

FAQ

How do I choose the right size for my stainless steel jaw eye swivel?

Selecting the right size involves matching the swivel’s load capacity with your rigging system’s requirements. First, calculate the weight of the load you’ll be lifting and ensure it aligns with the swivel’s rated capacity. Also, ensure that the jaw and eye fit securely with your rigging components, like shackles or hooks. If you’re unsure, our team is always ready to assist with sizing and selection.

What are the benefits of using stainless steel jaw eye swivels over other materials?

Stainless steel jaw eye swivels outperform other materials in terms of corrosion resistance, strength, and longevity. They hold up well in tough environments like marine, industrial, and chemical settings, where rust and wear are common issues. Unlike regular steel, stainless steel doesn’t corrode easily, ensuring a longer lifespan and less frequent replacements, saving you money in the long term.

Are the stainless steel jaw eye swivels tested for quality?

Yes, every stainless steel jaw eye swivel undergoes rigorous testing to ensure it meets safety and performance standards. We test for strength, corrosion resistance, and smooth functionality under load to ensure reliable performance in tough conditions. Our quality control process guarantees that the swivels you receive are safe, durable, and ready for use in demanding environments.