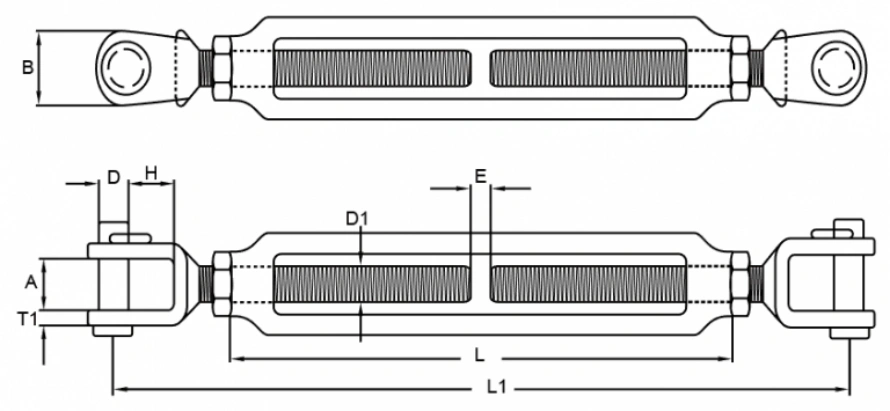

JAW JAW TURNBUCKLE DIAGRAM

JAW TO JAW TURNBUCKLE SPECIFICATIONS

| D1 | L1 | L | A | D | H | B | T1 | WT |

| mm | mm | mm | mm | mm | mm | mm | mm | KGS |

| M5 | 120 | 70 | 6.5 | 5 | 10 | 13 | 3 | 0.06 |

| M6 | 140 | 90 | 7.5 | 6 | 10 | 14 | 3 | 0.09 |

| M8 | 180 | 120 | 11 | 8 | 11 | 18.5 | 3 | 0.18 |

| M10 | 220 | 150 | 12 | 9 | 14 | 21 | 4 | 0.32 |

| M12 | 300 | 200 | 14 | 12 | 20 | 26 | 5 | 0.59 |

| M14 | 325 | 220 | 15 | 12 | 22 | 14.0 | 5 | 0.79 |

| M16 | 375 | 250 | 17 | 16 | 26 | 36 | 6 | 1.27 |

| M20 | 450 | 300 | 20 | 19 | 30 | 45.5 | 6 | 2.27 |

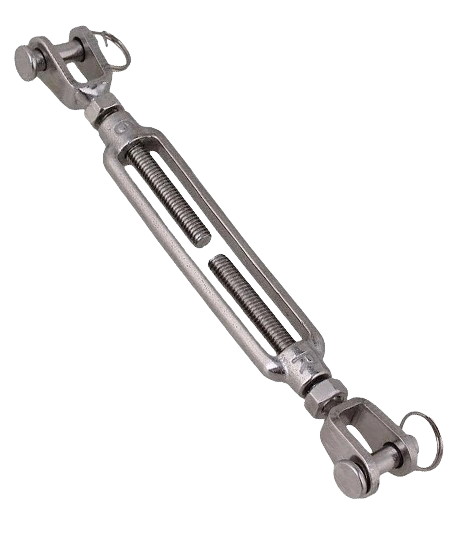

PRODUCT FEATURES

- Made from AISI304 or AISI316 stainless steel

- Corrosion-resistant and highly durable

- European Type design, suitable for various applications

- Available in standard and custom sizes

- Highly polished surface for enhanced appearance and protection

INSTRUCTIONS & CAUTIONS

Installation

To install the jaw jaw turnbuckle stainless steel, start by securing the wire rope into both jaw ends. Use the right pins or fasteners to hold it in place. Then, attach the other side to the rigging system, making sure both sides are aligned properly. Tighten the turnbuckle gently with a wrench, checking the tension as you go to ensure balance on both ends.

Avoid Over-tightening

When adjusting the turnbuckle, take care not to over-tighten. Tighten it gradually and ensure the tension is secure, but don’t stretch the wire rope too tightly. Over-tightening can strain the turnbuckle and rope, leading to damage or failure. Always check both ends for even tension to keep everything safe and functioning properly.

Inspection and Maintenance

Inspect the turnbuckle regularly for any signs of wear or corrosion. While the stainless steel construction is resistant to rust, it’s still important to check for any damage or loose connections. If any components are worn or damaged, replace them to maintain safe operation. Regular maintenance ensures the turnbuckle performs reliably over time.

Correct Usage

Always use the jaw jaw turnbuckle for its intended purpose—connecting wire ropes in rigging systems. Be sure to choose the correct size and specifications for your application. Using an improperly sized turnbuckle can cause poor performance or failure. Follow the manufacturer’s guidelines to get the best results and ensure safety.

OUR ADVANTAGES

Custom Engineered Solutions

Need something specific? We offer custom-engineered solutions tailored to your exact requirements. Whether you need custom sizes, finishes, or unique features for your jaw jaw turnbuckles, our team works with you to create the right product for your application. Our ability to customize gives you the flexibility to serve specialized markets.

Direct from Manufacturer

We provide products directly from our factory, cutting out middlemen and ensuring competitive pricing. You get high-quality jaw jaw turnbuckles at the best rates, without the extra markup. This direct-to-you model means faster lead times and more flexibility for your business, especially for bulk orders or custom requests.

One-Stop Sourcing

You won’t have to shop around for different parts. We offer a wide variety of rigging components, including jaw jaw turnbuckles, hooks, eyes, and more, all in one place. This makes it easy for wholesalers and large supermarkets to streamline their orders, reduce lead times, and consolidate shipments, helping you focus on growing your business.

Quality & Safety Guaranteed

We manufacture with precision and high standards. Every jaw jaw turnbuckle undergoes strict testing for durability and safety. Our products meet or exceed industry standards, providing peace of mind for your customers. When you order from us, you get a reliable, safe product designed to perform in demanding environments, like marine or industrial applications.

OUR REVIEWS

FAQ

What is the load capacity of a Jaw Jaw Turnbuckle Stainless Steel?

The load capacity of a jaw jaw turnbuckle stainless steel depends on its size and design. For large commercial orders, we can provide specific load ratings based on the material grade and dimensions. It is important to match the turnbuckle’s specifications with your wire rope’s strength for optimal performance and safety.

What is the difference between a jaw jaw turnbuckle and an eye eye turnbuckle?

A jaw jaw turnbuckle stainless steel has two jaw ends that connect directly to a clevis or hook, ideal for applications requiring more flexibility in rigging. An eye eye turnbuckle has circular eyelets on both ends and is better suited for connecting to threaded rods or other eye components. The choice depends on the specific rigging needs of your project.

How do I order Jaw Jaw Turnbuckles in bulk?

-

Contact our sales team: Reach out with your specifications such as size, material, and quantity.

-

Competitive pricing: We offer discounted rates for large wholesale orders.

-

Timely delivery: We ensure prompt delivery for your bulk orders.

-

Custom orders: We provide options for customizations to meet your business requirements.

How do I know which size Jaw Jaw Turnbuckle to order?

The size of the jaw jaw turnbuckle stainless steel depends on the diameter of the wire rope being used and the load requirements. We can guide you in selecting the right size based on your specific application. You can also provide us with the project details, and we’ll help you determine the correct dimensions and specifications for your needs.

Can I order Jaw Jaw Turnbuckles with specific threads or finishes?

Yes, we offer jaw jaw turnbuckle stainless steel in various thread types and finishes to suit different rigging systems. You can request specific thread sizes or custom finishes such as polished, matte, or galvanized. Our engineering team is happy to assist with customizing the turnbuckles to meet your project’s exact requirements.