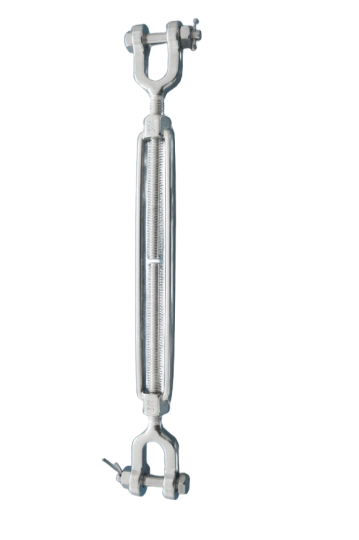

DIAGRAM

SPECIFICATIONS

| SIZE | L | L1 | A | D | B | H |

| in | in | in | in | in | in | in |

| 1/4 | 4 | 7.15 | 0.45 | 0.24 | 0.9 | 0.62 |

| 5/16 | 4.5 | 8.61 | 0.49 | 0.24 | 1 | 0.87 |

| 3/8 | 6 | 10.45 | 0.53 | 0.31 | 1.08 | 0.87 |

| 1/2 | 6 | 11.88 | 0.67 | 0.39 | 1.36 | 1.06 |

| 1/2 | 9 | 14.88 | 0.67 | 0.39 | 1.36 | 1.06 |

| 1/2 | 12 | 17.88 | 0.67 | 0.39 | 1.36 | 1.06 |

| 5/8 | 6 | 13.3 | 0.81 | 0.47 | 1.68 | 1.31 |

| 5/8 | 9 | 16.3 | 0.81 | 0.47 | 1.68 | 1.31 |

| 5/8 | 12 | 19.3 | 0.81 | 0.47 | 1.68 | 1.31 |

| 3/4 | 6 | 14.62 | 1.02 | 0.63 | 1.97 | 1.5 |

| 3/4 | 9 | 17.62 | 1.02 | 0.63 | 1.97 | 1.5 |

| 3/4 | 12 | 20.62 | 1.02 | 0.63 | 1.97 | 1.5 |

| 7/8 | 6 | 16 | 1.18 | 0.79 | 2.43 | 1.75 |

| 7/8 | 12 | 22 | 1.18 | 0.79 | 2.43 | 1.75 |

| 1 | 6 | 17.6 | 1.3 | 0.87 | 2.63 | 2.06 |

| 1 | 12 | 23.6 | 1.3 | 0.87 | 1.3 | 2.06 |

| 1-1/4 | 12 | 26.46 | 1.83 | 1.12 | 3.6 | 2.81 |

| 1-1/2 | 12 | 27.88 | 2.05 | 1.38 | 3.96 | 2.81 |

PRODUCT FEATURES

- Corrosion-resistant 304 or 316 stainless steel

- Precision-cast jaw to jaw fittings for secure connection

- Quick and easy attachment with bolt or clevis pins

- Available in standard dimensions with UNC thread for versatility

INSTRUCTIONS & CAUTIONS

Proper Installation

To install the jaw to jaw turnbuckle, attach the jaw fittings to your rigging system using bolts or clevis pins. Ensure both ends are securely fastened before adjusting the turnbuckle. It’s essential to tighten the turnbuckle properly, but not over-tighten, as this can damage the threads or fittings. Always verify the connection is stable before applying tension.

Inspect Regularly

Routine checks are crucial to maintaining the integrity of your rigging system. Inspect the turnbuckle regularly for any signs of wear, corrosion, or thread damage. If you find any issues, replace the turnbuckle immediately. Remember, these parts are under constant tension, and worn-out components can compromise safety and performance.

Avoid Over-Tightening

While adjusting the tension, make sure not to over-tighten the jaw to jaw turnbuckle. Over-tightening can lead to damage of the turnbuckle’s body or the jaw fittings, affecting their functionality and lifespan. Follow manufacturer specifications for proper tension levels and always ensure your system is not under excessive stress.

Select the Right Turnbuckle for Your Load

Choose the appropriate size and load capacity for your specific rigging needs. US Type Jaw to Jaw Turnbuckles come in various sizes and capacities. Using a turnbuckle with an insufficient load rating could lead to failure under stress. If you’re unsure about which one to choose, consult with our team to get the right fit for your application.

OUR ADVANTAGES

Custom-Engineered Solutions

We understand that every project has unique requirements. That’s why we offer custom-engineered jaw to jaw turnbuckles tailored to your specific needs. Whether it's special dimensions, load capacities, or materials, we work with you to provide the perfect turnbuckle for your rigging system, ensuring it performs reliably in your demanding environment.

Direct from Manufacturer

By sourcing directly from Powerful Machinery, you bypass middlemen, resulting in quicker turnaround times, lower prices, and better quality control. Our direct-to-customer approach ensures you get the exact product you need at a competitive price, with the convenience of dealing with us, the manufacturer, for any questions or custom requests.

Quality & Safety Assurance

Quality and safety are non-negotiable for us. Our jaw to jaw turnbuckles are made from high-grade stainless steel and undergo stringent testing to meet international standards. We prioritize your safety and ensure that every product delivered to you is reliable, durable, and performs as expected under heavy-duty use in industrial, marine, and construction applications.

After-Sales Support & Service

Our commitment to service doesn't stop after the sale. We provide industry-leading after-sales support to ensure that your jaw to jaw turnbuckles continue to perform optimally. From technical guidance to troubleshooting, our team is here to assist you at every step. With us, you get peace of mind knowing help is always just a call away.

OUR REVIEWS

FAQ

How do I install a Jaw to Jaw Turnbuckle?

-

Attach Jaw Fittings:

Secure the jaw fittings to your rigging system using bolts or clevis pins. -

Ensure Secure Fastening:

Double-check that both ends of the turnbuckle are tightly fastened before proceeding with adjustments. -

Adjust Tension:

Rotate the central body of the turnbuckle to adjust the tension. Be sure not to over-tighten. -

Verify the Connection:

Always confirm that the connection is tight and secure before applying any load to the rigging system.

What are the advantages of using Jaw to Jaw Turnbuckles over other types?

Jaw to Jaw Turnbuckles provide a more secure and stable connection compared to hook and eye turnbuckles, making them ideal for high-tension or heavy-duty applications. The jaw fittings ensure a firm, quick attachment to various rigging hardware, reducing the risk of slippage or detachment under load. They’re particularly useful in industrial, construction, and marine environments.

How do I adjust the tension on a Jaw to Jaw Turnbuckle?

Adjusting the tension is simple. Rotate the central body of the turnbuckle to either tighten or loosen the rigging system. The movement of the jaw fittings will adjust the overall tension. Make sure the turnbuckle is securely fastened and never over-tighten, as it can damage the threads or rigging hardware.

How do I place an order for Jaw to Jaw Turnbuckles?

-

Contact Our Sales Team:

Reach out with your specifications, including quantity, material type, and any customization requests. -

Get Guidance:

Our sales team will guide you through the ordering process to ensure you select the right turnbuckle for your project. -

Receive Competitive Pricing:

We offer competitive pricing and bulk discounts to help you secure the best value. -

Enjoy Timely Delivery:

Rest assured, we provide timely delivery to meet your business’s project deadlines.