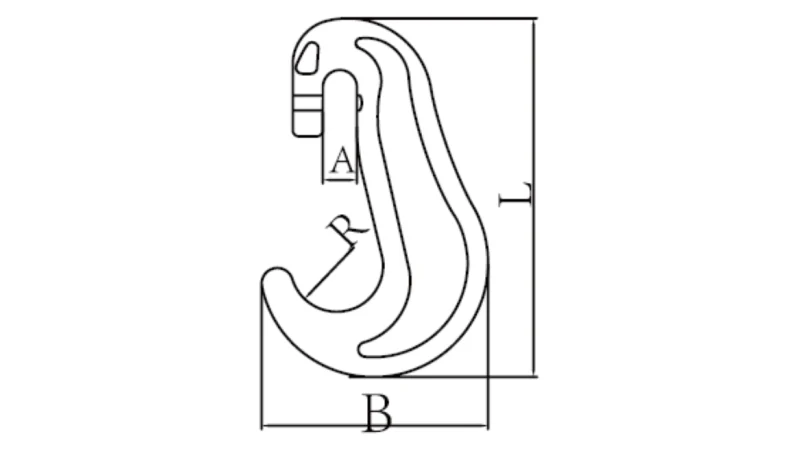

Product Specifications

| SIZE | WEIGHT | WLL | M.B.S. | DIMENSIONS(MM) | |||

| MM | KG/PC | TON | TON | L | A | B | R |

| 9 | 0.5 | 2.5 | 10 | 143 | 13.5 | 90.5 | 18.5 |

| 11 | 0.85 | 3.75 | 15 | 177 | 15.5 | 109.5 | 22 |

| 13 | 1.38 | 5.4 | 20 | 205 | 17.7 | 129 | 25.5 |

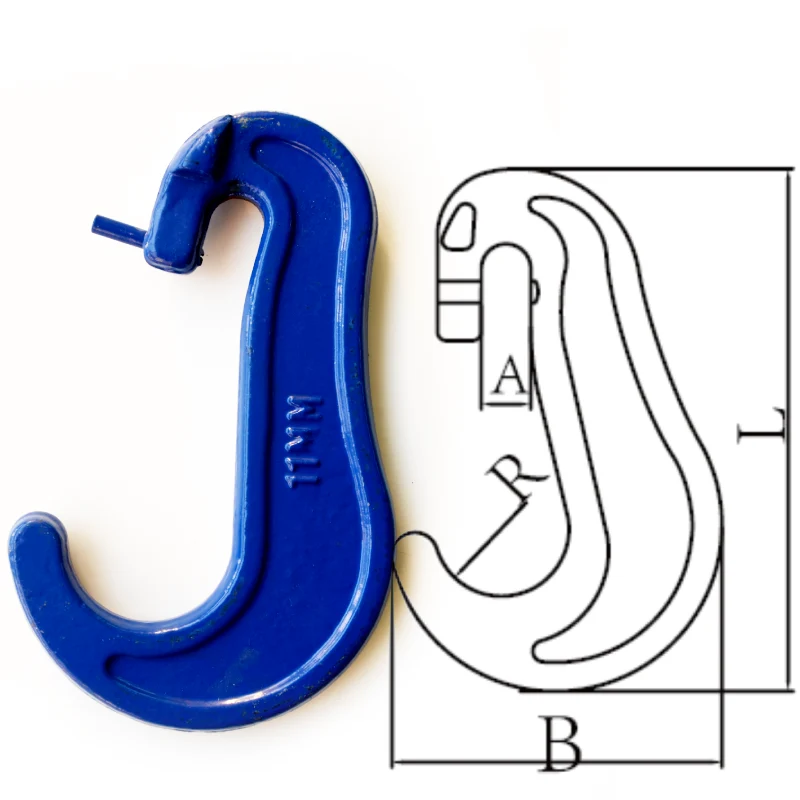

Products Diagrams

The hook’s open “C” shape allows quick chain connection, while the steel pin ensures a secure lock. This structure simplifies load tightening and provides reliable attachment under high tension and vibration.

Engineered with reinforced curvature and heat-treated pin joint, the C Hook distributes stress evenly. This minimizes bending and ensures consistent performance during dynamic lashing and lifting operations.

Material Specification

Grade:

Manufactured from Grade 80 or 100 steel, offering exceptional load strength and resistance to fatigue under repeated use.

Finish:

Hot-dip galvanized or powder-coated surface enhances corrosion resistance and protects the metal from environmental wear.

Attachment:

Equipped with a strong steel pin, ensuring firm locking with lashing chains and preventing accidental disengagement during operation.

Lashing C Hooks With Pin for Chains Type:

Slip-type C hook with locking pin, designed for quick assembly, secure restraint, and chain compatibility.

Material:

High-tensile forged alloy steel, heat-treated for superior strength, durability, and impact absorption during heavy-duty applications.

Application

Construction Industry

Used for securing loads, anchoring chains, and restraining materials on trucks, cranes, or scaffolding systems

Marine & Offshore

Ideal for cargo lashing, deck securing, and rigging in coastal and offshore operations under high moisture conditions.

Mining Industry

Applied in load stabilization, machinery restraint, and chain coupling under extreme vibration and heavy-load environments.

Advantages

Corrosion & Finish Protection

Galvanized or coated finish offers superior rust protection and ensures long-term use in outdoor and marine settings.

Customization & Traceability

Available in different pin sizes and finishes; each product batch is marked for traceability and quality verification.

Load Control & Durability

High-grade steel provides stable performance under tension, ensuring the hook maintains form and function over time.

Bulk Capacity & Lead Time

Large-scale production capacity with quick turnaround and reliable delivery schedules for global wholesale customers.

What Our Clients Say

FAQ

What are Lashing C Hooks With Pin for Chains primarily used for?

Lashing C Hooks With Pin are designed for securing, tightening, and connecting loads during transport or industrial operations. They are commonly used with lashing chains, ratchet systems, and tie-down assemblies to secure cargo on trucks, ships, or trailers. The integrated pin ensures the hook remains firmly locked during vibration or movement, minimizing load shift or accidental release.

What technical standards and load capacities do these hooks meet?

Our Lashing C Hooks comply with international rigging and lashing standards, including EN, ASTM, and ISO certifications, depending on client requirements. The hooks are proof-tested to 2.5 times the Working Load Limit (WLL) and break-tested to 4 times WLL to ensure maximum safety. Typical load capacities range from 1 ton to 13 tons, depending on chain size and grade.

What materials and heat treatments are used for durability?

Each hook is manufactured from forged alloy steel or Grade 80/100 carbon steel, then subjected to precision heat treatment and tempering. This process increases tensile strength, enhances toughness, and prevents fatigue failure during continuous operation. The steel pin is also hardened to resist wear, ensuring long-term reliability under repeated tensioning cycles.

Can Lashing C Hooks With Pin be customized for specific chain sizes or applications?

Yes, we offer OEM and ODM customization services. Clients can specify hook dimensions, pin diameters, surface finishes, and chain compatibility. We also provide laser-etched load markings and traceable batch codes for enhanced product identification and quality control. Custom packaging and branding are available for distributors and large importers.

How do you ensure product safety and quality consistency?

Powerful Machinery follows a strict ISO 9001-certified quality management system. Every production batch undergoes dimensional inspection, hardness testing, load testing, and magnetic particle crack detection. Material certificates and test reports are available upon request. Our in-house lab ensures that each hook meets the required mechanical and performance standards before shipping.

What are the best practices for using and maintaining these hooks?

Always inspect hooks for wear, deformation, or corrosion before each use. The pin should move freely and lock securely. Avoid overloading beyond the rated WLL. Regularly clean and lubricate the pin mechanism to prevent jamming. Store hooks in a dry, ventilated area when not in use. For maximum lifespan, use with matching chain grades and certified rigging components only.

Do you supply to global distributors and industrial buyers?

Yes, Powerful Machinery exports worldwide and serves wholesalers, engineering firms, OEM manufacturers, and fleet operators. We offer bulk pricing, container consolidation, and fast delivery through major logistics networks. Our factory supports custom inspection certificates and third-party quality audits upon request.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.