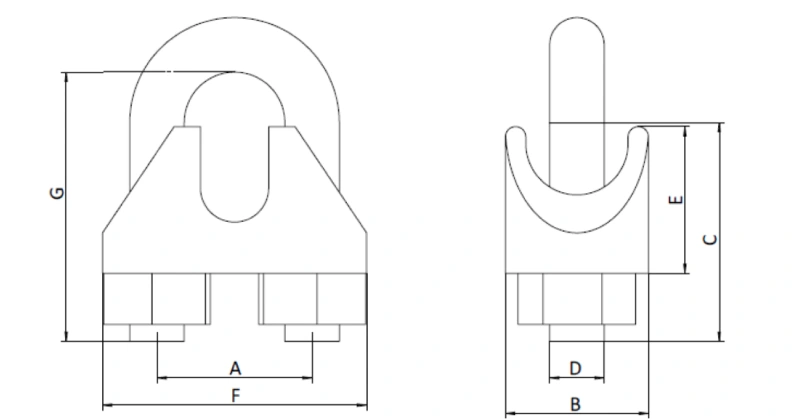

Product Specifications

| SIZE | A | B | C | D | E | F | G | W/100PCS |

| MM | MM | MM | MM | MM | MM | MM | MM | KGS |

| 5 | 7 | 13 | 13 | 5 | 13 | 25 | 20 | 2.08 |

| 6.5 | 8 | 16 | 17 | 6 | 14 | 30 | 26 | 4 |

| 8 | 10 | 20 | 20 | 8 | 18 | 39 | 33 | 8.2 |

| 10 | 12 | 20 | 24 | 8 | 21 | 40 | 38 | 9.2 |

| 13 | 15 | 28 | 30 | 12 | 29 | 55 | 52 | 27.5 |

| 16 | 18 | 32 | 35 | 14 | 35 | 64 | 64 | 43 |

| 19 | 22 | 32 | 36 | 14 | 40 | 68 | 69 | 49 |

| 22 | 24 | 34 | 40 | 16 | 44 | 74 | 80 | 68 |

| 26 | 26 | 38 | 50 | 20 | 51 | 84 | 91 | 117 |

| 30 | 34 | 41 | 55 | 22 | 59 | 95 | 107 | 140 |

| 34 | 38 | 45 | 60 | 22 | 67 | 105 | 119 | 213 |

| 40 | 44 | 49 | 65 | 24 | 77 | 117 | 135 | 268 |

Products Diagrams

This wire rope clip features a sturdy U-bolt and precision-machined saddle that ensures firm rope grip and simple tightening. The compact design supports easy installation and reliable load control, offering a safe, efficient way to form eyes or secure wire rope connections.

Each Malleable Wire Rope Clip Type DIN 13411-5 is manufactured with uniform thread depth and accurate saddle curvature for perfect alignment. Available in multiple sizes, it ensures compatibility with standard wire ropes, maintaining durability and consistent pressure distribution during use.

Material Specification

Grade:

Made to DIN 13411-5 standards, ensuring uniform mechanical strength, precise dimensions, and dependable performance for general lifting and rigging applications.

Finish:

Hot-dip galvanized or electro-galvanized finish delivers long-term protection against corrosion and environmental wear in outdoor or marine conditions.

Attachment:

U-bolt and saddle system with double nuts for stable tightening and secure rope fastening during installation and operation.

Type:

European standard clip design suitable for various wire rope diameters, ensuring compatibility and reliability for light to medium-duty use.

Material:

High-quality malleable iron body with hardened steel nuts, combining durability, affordability, and resistance to deformation under tension.

Application

Construction Industry

Used for securing scaffolding lines, cable fences, and lifting guides, ensuring stable and quick assembly in temporary or permanent construction setups.

Marine & Offshore

Ideal for rigging, deck lines, and general marine fastening where corrosion resistance and quick adjustment are critical.

Mining Industry

Applied in securing wire ropes, barrier lines, and support systems, providing safe, strong connections in rugged mining environments.

Advantages

Corrosion & Finish Protection

Durable galvanized coating offers long-lasting resistance to rust and weather exposure, ensuring reliability even in harsh outdoor or marine environments.

Customization & Traceability

OEM options available including custom logo, finish, and packaging with full quality traceability and batch certification for global distributors.

Load Control & Durability

Designed for consistent load grip without slippage, maintaining secure tension across rope connections and enhancing operational safety.

Bulk Capacity & Lead Time

Automated production lines guarantee stable bulk supply, competitive factory pricing, and fast turnaround for large-scale industrial and wholesale orders.

What Our Clients Say

FAQ

What is the purpose of a Malleable Wire Rope Clip Type DIN 13411-5?

It’s used to secure the ends of wire ropes, form eyes, or join two cables together. The simple U-bolt and saddle design allows for quick installation both in workshops and on job sites.

How does your wire rope clip differ from others on the market?

Our clips are produced under strict DIN 13411-5 standards using high-grade malleable iron. Each piece undergoes dimensional inspection and load testing to guarantee safety and consistent performance.

Can I request custom branding or finishes?

Yes. We support OEM customization with options like laser-engraved logos, surface coatings, color finishes, and personalized packaging to strengthen your brand identity in the market.

How can I ensure proper installation?

Place the saddle on the live end of the rope and the U-bolt on the dead end. Tighten evenly and recheck after load is applied to ensure safety.

Do you provide certificates or testing documents?

Every batch comes with Material Test Certificates (MTC), compliance reports, and inspection records for full traceability and quality assurance.

What are your production and delivery timelines?

For standard orders, lead time is 15–25 days. Large or customized orders are efficiently handled through our automated forging and galvanizing systems.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.