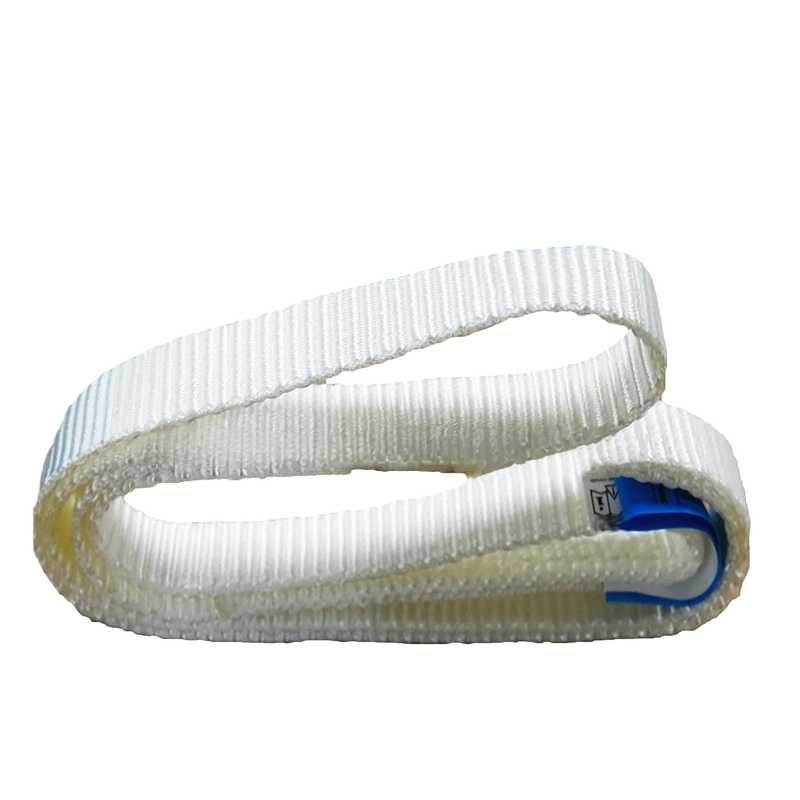

ONE WAY SLING SPECIFICATIONS

| Code | WLL (kgs) | Webbing Width (mm) |

| DOWS-75 | 750 | 50 |

| DOWS-100 | 1000 | 50 |

| DOWS-140 | 1400 | 50 |

ONE WAY SLING INFORMATION

-

Material: Stainless Steel for strength and corrosion resistance.

-

Design: Swage design for secure and reliable connections.

-

Application: Ideal for heavy-duty lifting in steel, construction, cargo loading, and marine industries.

-

Safety: High strength-to-weight ratio, ensuring safety and performance.

-

Versatility: Suitable for both one-way use and reusable configurations based on the application.

INSTRUCTIONS & CAUTIONS

Always Check the Working Load Limit

Before using a one-way sling, double-check the Working Load Limit (WLL) on the label. It’s important that the load doesn’t exceed this limit. A quick check ensures you’re using the right sling for the task and helps prevent accidents. Never compromise on this step to maintain safety during lifting operations.

Inspect Before Each Use

Make it a habit to inspect the one-way sling before every lift. Look for any signs of wear, like cuts or fraying. Even though these slings are usually meant for single-use, checking the condition before use ensures you’re not risking a failure. If you spot any damage, replace the sling immediately.

Avoid Overloading the Sling

Don’t overload the one-way sling. Always use the sling within its WLL to prevent damage or failure. Overloading can affect the sling’s strength and safety. Keep the load balanced and make sure you’re following the manufacturer’s guidelines. Training your team to understand these limits is key to safe operations.

Proper Disposal After Use

While one-way slings can sometimes be reused, they’re typically designed for single-use. Once the job is done, check the sling one last time for any damage. If it’s no longer safe to use, dispose of it properly. This helps keep your operations safe and ensures worn-out slings don’t end up in future jobs.

OUR ADVANTAGES

Tailored Solutions for Your Business

Every business has different needs, and we get that. That’s why we offer customized solutions to fit exactly what you’re looking for. Need a specific size, safety factor, or setup? We’ll work with you to make sure our products are perfectly tailored to your requirements, so your investment works harder for you.

High-Quality Standards & Compliance

We don’t compromise on quality. At Powerful Machinery, we stick to high-quality standards and make sure our products meet all the latest industry regulations. You can rest easy knowing every item is rigorously tested and certified to meet international standards. With us, you’re getting reliable products built to last.

Fast, Reliable Delivery

With us, you won’t have to worry about delays. We prioritize fast and reliable delivery, making sure your orders arrive on time—whether it’s a bulk order or a quick restock. We’re committed to getting you what you need, right when you need it, so your operations can keep moving smoothly without disruptions.

Personalized Customer Support

We make sure to offer personalized customer support that’s always available when you need it. Whether you're selecting the right slings or have specific questions, our team is here to guide you. We focus on giving you quick, efficient service, making sure you get what you need—when you need it. We’re here to make your experience easier.

FAQ

What are one-way lifting slings, and how are they different from other slings?

One-way lifting slings are designed for single-use, making them perfect for temporary lifting jobs. Unlike reusable slings, these are typically discarded after one use to maintain safety. They’re great for handling materials in industries like steel, construction, and cargo. They’re lightweight and cost-effective for quick lifts without the need for long-term storage.

Can one-way lifting slings be used for all types of loads?

One-way lifting slings are versatile but are best used for light to medium loads. They’re commonly used in industries like steel, construction, and wood handling. For heavier or more complex loads, make sure the sling’s WLL is adequate, or consider using multi-layer slings. If you’re unsure, feel free to reach out for guidance on the best sling for your needs.

Can one-way slings be used for lifting at different angles?

Yes, one-way slings can be used at various angles, but be mindful of the lifting angle as it can reduce the sling’s strength. Always aim for a lifting angle as close to 90 degrees as possible to maximize the sling’s performance and reduce the risk of damage. Refer to the sling’s instruction label for guidelines on safe usage at angles.

How long can I use a one-way lifting sling before it needs replacing?

Most one-way slings are designed for single-use. However, some can be reused if in good condition. Inspect each sling thoroughly before reuse, and make sure it’s still within its WLL. For repeated use, consider multi-use slings for long-term applications. Always follow the manufacturer’s guidelines to ensure safety.

What industries use one-way lifting slings?

One-way lifting slings are perfect for industries like construction, steel, wood production, logistics, and cargo handling. They’re designed for light-duty and temporary lifting tasks, offering an easy and cost-effective way to handle materials. Whether you’re lifting small goods or medium-sized loads, one-way slings offer convenience and reliability.