Product Specifications

| SIZE | SIZE | b | c | d | e | f | PROOF LOAD | WEIGHT |

| IN. | MM | MM | MM | MM | MM | MM | TON | KG/PC |

| 3/8″ | 10 | 20 | 25 | 45 | 6 | 38 | 2 | 0.14 |

| 1/2″ | 12 | 25 | 35 | 60 | 8 | 50 | 3.5 | 0.33 |

| 5/8″ | 16 | 32 | 45 | 70 | 10 | 64 | 5.5 | 0.53 |

| 3/4″ | 19 | 38 | 50 | 85 | 12 | 76 | 7.5 | 0.77 |

| 7/8″ | 22 | 42 | 60 | 102 | 13 | 89 | 9.6 | 1.27 |

| 1″ | 25 | 50 | 70 | 115 | 16 | 100 | 13 | 2 |

| 1 1/8″ | 28 | 57 | 76 | 130 | 18 | 114 | 15.75 | 2.9 |

| 1 1/4″ | 32 | 64 | 85 | 145 | 19 | 128 | 20 | 3.44 |

| 1 3/8″ | 35 | 70 | 95 | 159 | 21 | 140 | 23.63 | 5.11 |

| 1 1/2″ | 38 | 76 | 100 | 170 | 22 | 152 | 29 | 6.58 |

| 1 3/4″ | 44 | 88 | 120 | 200 | 26 | 178 | 39 | 9.99 |

| 2″ | 50 | 100 | 140 | 230 | 30 | 203 | 50 | 14.98 |

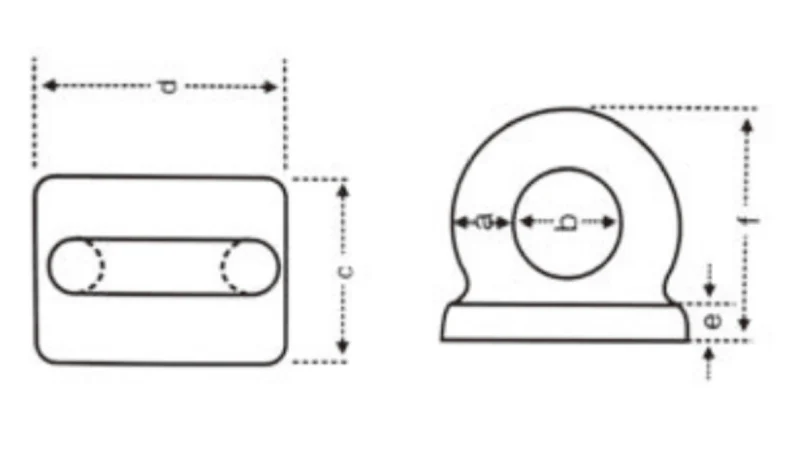

Products Diagrams

The rectangular base offers a wide, stable surface for welding. The centered eye ensures even load distribution, reducing stress on weld joints. Smooth contours minimize wear on ropes, chains, or hooks, ensuring safe and efficient load handling.

Available in multiple sizes and load capacities, our plates can fit different lifting configurations. Each unit is precision-machined for uniform thickness and accurate hole dimensions, guaranteeing easy installation and reliable performance in any industrial or marine setup.

Material Specification

| Grade: | Made from high-tensile carbon steel, engineered for superior load resistance and long-term structural integrity. |

| Finish: | Zinc-plated or hot-dip galvanized surface for outstanding corrosion protection in marine or outdoor environments. |

| Attachment: | Weld-on design enables permanent, secure attachment to steel structures, decks, or heavy machinery. |

| Rectangular Base Eye Plates Type: | Forged rectangular base with integrated eye loop, optimized for lifting and lashing applications. |

| Material: | Industrial-grade forged steel, offering the ideal balance of strength, durability, and weldability. |

Application

Construction Industry

Used for securing lifting points on cranes, scaffolding, or structural frames, ensuring stability and safe handling of heavy materials on construction sites.

Marine & Offshore

Perfect for decks, ship hulls, and offshore platforms where corrosion resistance and strong anchoring points are critical.

Mining Industry

Provides safe lifting and anchoring for heavy mining machinery, containers, and transport equipment in harsh environments.

Advantages

Corrosion & Finish Protection

Each plate is coated for maximum corrosion resistance, ensuring long service life even in salty, humid, or chemically harsh environments.

Customization & Traceability

We offer size, finish, and marking customization, with full batch traceability to meet industrial compliance requirements.

Load Control & Durability

Precision-forged for consistent strength, our plates handle high loads safely without deformation or failure.

Bulk Capacity & Lead Time

Large production capacity and streamlined logistics ensure fast delivery for bulk or OEM orders without sacrificing quality.

What Our Clients Say

FAQ

Yes, we provide customization for size, thickness, and eye diameter. Our engineering team supports OEM and ODM requests to fit specific lifting or deck-mounting requirements.

We use high-tensile carbon steel, forged and heat-treated for maximum durability. Depending on your environment, you can choose between zinc-plated or hot-dip galvanized finishes for extra corrosion resistance.

What materials are used for your Rectangular Base Eye Plates?

We use high-tensile carbon steel, forged and heat-treated for maximum durability. Depending on your environment, you can choose between zinc-plated or hot-dip galvanized finishes for extra corrosion resistance.

Are these plates suitable for marine or offshore use?

We offer marine-grade finishes that resist corrosion from saltwater and humidity, making them ideal for shipbuilding, docks, and offshore rigs.

Do you offer bulk or wholesale pricing?

Yes, we specialize in supplying distributors, contractors, and OEM manufacturers. Bulk orders receive tiered pricing and prioritized production schedules.

How do you ensure product quality and safety?

Every plate undergoes dimensional inspection, material testing, and load verification. Certificates and traceability documents are available upon request.

What is the typical lead time for orders?

Standard sizes are available in stock. Custom and bulk orders are usually delivered within 2–4 weeks, depending on quantity and finish requirements.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.