DIAGRAM

SPECIFICATIONS

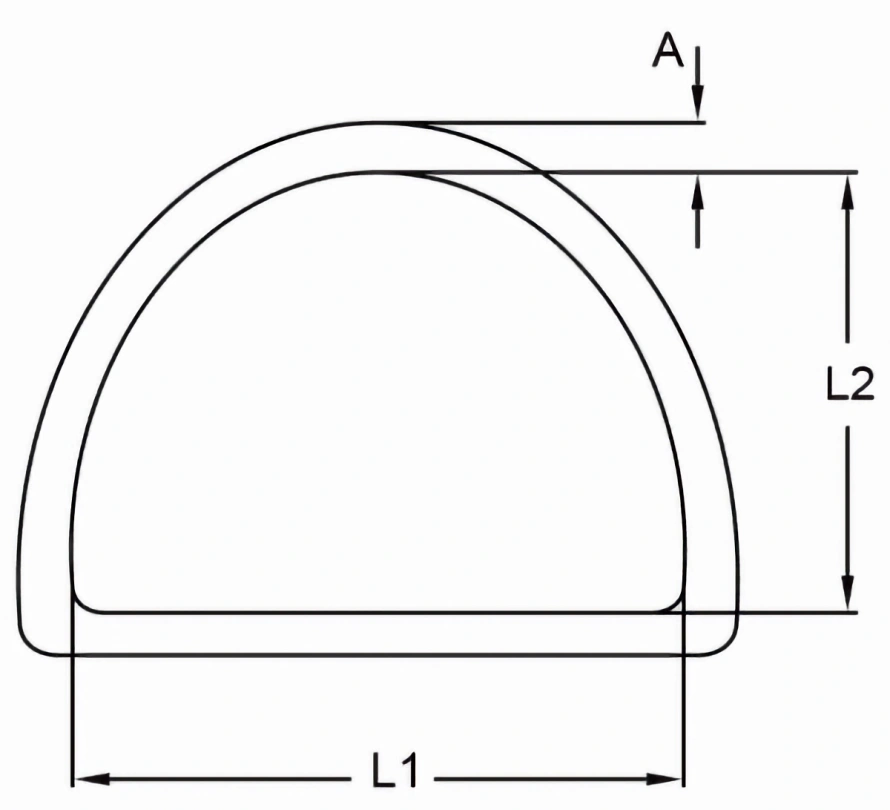

| ITEM NO | A | L1 | L2 | WT | ITEM NO | A | L1 | L2 | WT | |

| mm | mm | mm | mm | mm | mm | mm | mm | |||

| HF0437-A/B0315 | 3 | 15 | 12 | 0.003 | HF0437-A/B0530 | 5 | 30 | 27 | 0.016 | |

| HF0437-A/B0320 | 3 | 20 | 17 | 0.0039 | HF0437-A/B0540 | 5 | 40 | 37 | 0.02 | |

| HF0437-A/B0330 | 3 | 30 | 27 | 0.005 | HF0437-A/B0550 | 5 | 50 | 47 | 0.026 | |

| HF0437-A/B0420 | 4 | 20 | 17 | 0.007 | HF0437-A/B0630 | 6 | 30 | 27 | 0.025 | |

| HF0437-A/B0425 | 4 | 25 | 22 | 0.009 | HF0437-A/B0640 | 6 | 40 | 37 | 0.032 | |

| HF0437-A/B0430 | 4 | 30 | 27 | 0.011 | HF0437-A/B0650 | 6 | 50 | 47 | 0.041 | |

| HF0437-A/B0440 | 4 | 40 | 37 | 0.014 | HF0437-A/B0850 | 8 | 50 | 47 | 0.074 | |

| HF0437-A/B0525 | 5 | 25 | 22 | 0.0147 | HF0437-A/B0860 | 8 | 60 | 57 | 0.09 | |

TRAWL BLOCK DESIGN

- Material: Available in 304 or 316 stainless steel for maximum durability

- Finish: Polished for a sleek, rust-resistant surface

- Sizes: Available in 3mm, 4mm, 5mm, 6mm, and 8mm diameters to suit various needs

- Corrosion Resistance: Ideal for use in marine and industrial environments

- Applications: Perfect for marine, rigging, webbing, and utility uses

INSTRUCTIONS & CAUTIONS

Check Load Capacity Before Use

Before using the stainless steel D ring, make sure it’s rated for the load you intend to use it for. These rings are designed to handle a range of loads, but exceeding their capacity can cause failure. Always verify the weight limits and match them with your project’s requirements. If you’re uncertain about the right size or strength, feel free to reach out to our team for expert advice.

Inspect Regularly for Wear and Tear

Routine inspections are crucial to maintaining the performance of your stainless steel D rings. Check them for any signs of cracks, corrosion, or deformation, especially if exposed to harsh environments. Even the best materials can wear out over time, so catching any issues early can help prevent failures that could disrupt your operations.

Ensure Proper Installation

When installing stainless steel D rings, ensure they are securely attached to the rigging system or strap. Loose or improperly connected rings can lead to accidents or damage. Always use the correct fittings for a safe and secure installation. A quick check before each use will go a long way in preventing potential issues.

Avoid Using for Overhead Lifting

While stainless steel D rings are extremely durable, they are not intended for overhead lifting applications. Using them for lifting heavy loads in an overhead capacity can result in failure. Stick to using them for securing straps, bags, and other non-lifting applications to maintain safety and performance.

OUR ADVANTAGES

Custom-Engineered Solutions

Need custom sizes or specifications? We specialize in custom-engineered solutions tailored to your exact project requirements. Plus, with our efficient logistics and transportation system, we ensure fast delivery, even for bulk orders. You won’t have to wait long for your stainless steel D rings, no matter how complex or large your order is, so your projects stay on schedule.

Direct-from-Manufacturer

At Powerful Machinery, we sell our stainless steel D rings directly from the manufacturer, cutting out middlemen and passing those savings on to you. This direct approach also ensures you get the highest quality products at competitive prices. We take full responsibility for the quality control process, so you can trust that each D ring meets the highest standards of durability and performance.

Fully Certified for Safety & Performance

Our stainless steel D rings are fully certified, meeting rigorous industry standards for safety and performance. We prioritize quality assurance to ensure each product delivers reliable results. Whether you’re using them in marine, industrial, or rigging applications, our D rings are designed for secure and safe usage, providing peace of mind on every project.

One-Stop Sourcing for Rigging Components

Powerful Machinery offers a comprehensive selection of rigging and lifting hardware, making us your one-stop source for all rigging needs. In addition to our stainless steel D rings, we provide a wide range of related products that fit seamlessly into your project. From webbing to chains, we’ve got the right components to complete your rigging system, saving you time and effort.

OUR REVIEWS

FAQ

How do I choose the right size stainless steel D ring?

-

Consider the Load Capacity:

Choose a D ring that matches the load it will bear. Ensure the D ring’s strength aligns with the weight and stress it will be subjected to in your rigging setup. -

Check the Material Compatibility:

Determine what material you’ll be attaching the D ring to, whether it’s rope, webbing, or chain. The D ring must fit securely with these components. -

Match the Diameter to Your Rigging Components:

Ensure that the D ring diameter matches the size of your rigging components for a secure connection. A proper fit is essential to ensure safety and prevent failure. -

Get Expert Assistance:

If you’re unsure, our team is ready to help you select the ideal D ring size based on your project’s unique needs, ensuring optimal strength and reliability.

Can stainless steel D rings be used for overhead lifting?

While stainless steel D rings are strong and corrosion-resistant, they are generally not recommended for overhead lifting. For lifting applications, consider choosing D rings with specific certifications for lifting or consult with us to ensure you’re selecting the right component for your needs. Our customer service team is happy to guide you through the best options for lifting tasks.

What is the difference between 304 and 316 stainless steel D rings?

304 stainless steel offers good corrosion resistance for most applications, but 316 stainless steel is superior, especially in marine and harsh chemical environments. The addition of molybdenum in 316 stainless steel makes it more resistant to pitting, rust, and chloride ions. For marine, industrial, or highly corrosive applications, 316 stainless steel D rings are the preferred choice.

How do I install stainless steel D rings in my rigging system?

Installing stainless steel D rings is straightforward. Simply connect the ring to your rigging system using the appropriate fittings, whether it’s a hook, rope, or chain. Make sure the D ring is securely attached and that the load is evenly distributed. Always follow installation guidelines and perform a quick inspection to ensure everything is properly installed before use.

What are the benefits of using stainless steel D rings over other materials?

Stainless steel D rings are more durable and resistant to corrosion compared to rings made from other materials like galvanized steel. They offer superior strength, reliability, and long-term performance in harsh environments, including saltwater exposure, chemicals, and extreme weather. Stainless steel D rings are low-maintenance and provide a long-lasting, cost-effective solution for your rigging needs.