DIAGRAM

SPECIFICATIONS

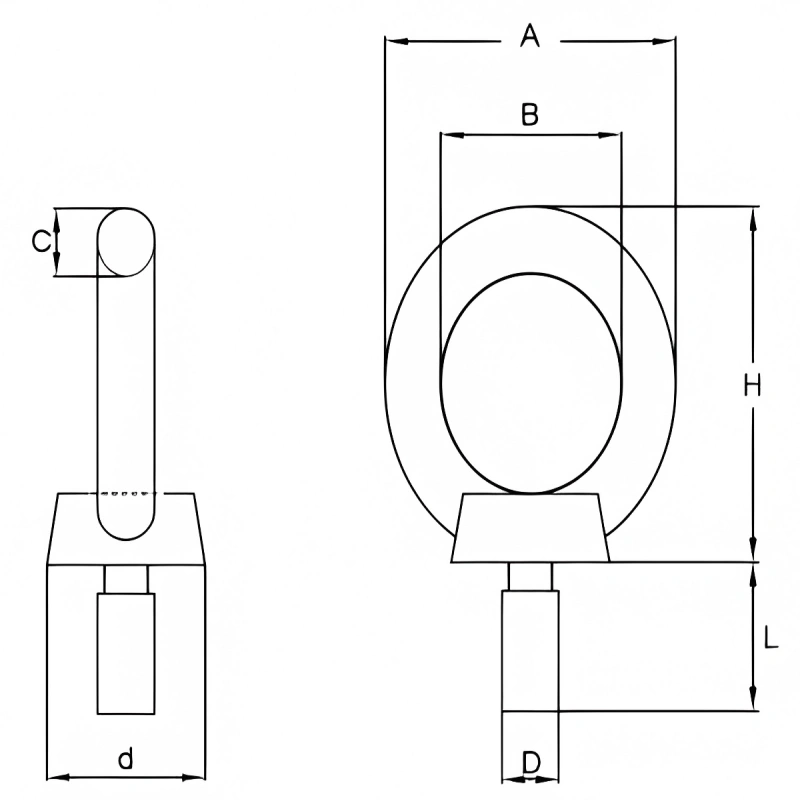

| ITEM NO | SIZE | A | B | C | D | H | L | WT |

| mm | mm | mm | mm | mm | mm | mm | KGS | |

| PF0054-A/B0006 | M6 | 25 | 15 | 4.5 | 6 | 28 | 13 | 0.014 |

| PF0054-A/B0008 | M8 | 31.5 | 20 | 6 | 8 | 34 | 14.5 | 0.025 |

| PF0054-A/B0010 | M10 | 39.5 | 25 | 7 | 10 | 41 | 18 | 0.051 |

| PF0054-A/B0012 | M12 | 49 | 30 | 9 | 12 | 51 | 22 | 0.093 |

| PF0054-A/B0016 | M16 | 58 | 34 | 12 | 16 | 59 | 26 | 0.165 |

| PF0054-A/B0020 | M20 | 70 | 39 | 16 | 20 | 71 | 30 | 0.28 |

| PF0054-A/B0022 | M22 | 79 | 44.5 | 17.5 | 22 | 81 | 34 | 0.469 |

PRODUCT FEATURES

- Material: AISI 304/316 stainless steel

- Standard: JIS 1168

- Finish: High-polished and electric-polished

- Application: Lifting, securing, and rigging

- Easy Installation: Fits threaded fittings

INSTRUCTIONS & CAUTIONS

Ensure Proper Installation

When installing the JIS 1168 Stainless Steel Lifting Eye Bolt, make sure it is fully threaded into the fitting to achieve a secure hold. The eye bolt should be screwed in until the mating faces are tightly engaged. Always check the threads for any damage or contamination before installation to ensure a safe, tight connection.

Do Not Exceed Load Limits

Always check the rated lifting capacity for your specific eye bolt size before use. Exceeding the maximum load rating can lead to failure, compromising safety. If you’re lifting heavy or irregularly shaped loads, ensure the eye bolt is properly rated for the job and consider using multiple lifting points for stability.

Inspect Regularly for Wear

Inspect your stainless steel lifting eye bolts regularly for any signs of corrosion, wear, or deformation. Even high-quality stainless steel can degrade over time if exposed to harsh conditions. Clean the eye bolt to remove dirt, salt, or other corrosive elements, and always replace bolts showing signs of wear or damage.

Avoid Angular Lifting

JIS 1168 Eye Bolts are designed for vertical lifting only. If you attempt to lift at an angle, you risk reducing the load capacity of the eye bolt. For angular lifting, it’s recommended to use specialized equipment like hoist rings that are designed for such applications. Always adhere to the manufacturer’s guidelines to ensure safety.

OUR ADVANTAGES

Custom Solutions Tailored

We understand that every project is different. That's why Powerful Machinery offers custom-engineered solutions to meet your unique needs. Whether you require specific sizes, finishes, or load ratings, we work closely with you to provide a product that fits your exact specifications. Our flexible approach ensures that you get the right solution for the job, every time.

Premium Quality with Guaranteed Safety

At Powerful Machinery, we prioritize quality and safety. All our products meet rigorous industry standards and are manufactured using high-grade materials, including stainless steel. We take pride in ensuring that every eye bolt and lifting hardware is robust, safe, and reliable for your lifting operations, giving you the assurance that our products will perform under pressure.

One-Stop Sourcing

Why work with multiple suppliers when you can get it all in one place? Powerful Machinery offers one-stop sourcing, providing a wide range of rigging and lifting solutions, from eye bolts to custom parts. This means you save time and streamline your operations. Whatever your project requires, we’ve got you covered, making your procurement process seamless and efficient.

Fast Delivery & Reliable After-Sales Support

We know that time is money in the industry, which is why we offer fast and efficient logistics to ensure timely deliveries. Plus, our after-sales support is second to none. If you need assistance, have technical questions, or require any adjustments post-purchase, our dedicated customer service team is always available to provide quick resolutions and keep your project on track.

OUR REVIEWS

FAQ

Can JIS Stainless Steel Lifting Eye Bolts be used for lifting at angles?

JIS eye bolts are designed for vertical lifting. For angular lifting, we recommend using hoist rings or shoulder bolts, as the lifting capacity of eye bolts decreases at angles. Using the correct lifting hardware ensures safety and prevents overloading the eye bolts, which can result in damage or failure during operation.

What is the maximum load capacity of JIS Stainless Steel Lifting Eye Bolts?

The load capacity of JIS Stainless Steel Lifting Eye Bolts depends on the size and thread type. Typically, these eye bolts can support weights ranging from hundreds to thousands of kilograms. Always check the load rating specific to your eye bolt size to ensure it matches the needs of your project. Never exceed the rated capacity to prevent accidents or equipment failure.

How do I remove JIS Stainless Steel Lifting Eye Bolts from a structure?

-

Ensure the Load is Released: Before removing the eye bolt, make sure the load is completely released to prevent accidents.

-

Unthread Carefully: Use the appropriate tools to unthread the eye bolt from the mating component. Proceed slowly and gently.

-

Use Penetrating Oil if Stuck: If the bolt is stuck, apply penetrating oil to loosen it. Be cautious not to damage the threads.

-

Clean the Bolt Threads: After removal, clean the threads to remove dirt or corrosion before reusing them. This ensures a proper fit for the next installation.