Product Specifications

| U.S. TYPE DROP FORGED G-210 SCREW PIN DEE SHACKLE | |||||||

| NOMINAL SIZE | WLL | WEIGHT | DIMENSIONS(IN.) | ||||

| IN. | TON | KG/PC | A | B | G | P | F |

| 1/4″ | 1/2 | 0.05 | 15/32″ | 5/16″ | 7/8″ | 1/4″ | 11/16″ |

| 5/16″ | 3/4 | 0.08 | 17/32″ | 3/8″ | 1-1/32″ | 5/16″ | 13/16″ |

| 3/8″ | 1 | 0.11 | 21/32″ | 7/16″ | 1-1/4″ | 3/8″ | 31/32″ |

| 7/16″ | 1-1/2 | 0.17 | 23/32″ | 1/2″ | 1-7/16″ | 7/16″ | 1-1/16″ |

| 1/2″ | 2 | 0.23 | 13/16″ | 5/8″ | 1-5/8″ | 1/2″ | 1-3/16″ |

| 5/8″ | 3-1/4 | 0.55 | 1-1/16″ | 3/4″ | 2″ | 5/8″ | 1-9/16″ |

| 3/4″ | 4-3/4 | 0.91 | 1-1/4″ | 7/8″ | 2-3/8″ | 3/4″ | 1-7/8″ |

| 7/8″ | 6-1/2 | 1.49 | 1-7/16″ | 1″ | 2-13/16″ | 7/8″ | 2-1/8″ |

| 1″ | 8-1/2 | 2.15 | 1-11/16″ | 1-1/8″ | 3-3/16″ | 1″ | 2-3/8″ |

| 1-1/8″ | 9-1/2 | 2.86 | 1-13/16″ | 1-1/4″ | 3-9/16″ | 1-1/8″ | 2-5/8″ |

| 1-1/4″ | 12 | 4.08 | 2-1/32″ | 1-3/8″ | 3-15/16″ | 1-1/4″ | 3″ |

| 1-3/8″ | 13-1/2 | 5.44 | 2-1/4″ | 1-1/2″ | 4-3/8″ | 1-3/8″ | 3-5/16″ |

| 1-1/2″ | 17 | 7.33 | 2-3/8″ | 1-5/8″ | 4-13/16″ | 1-1/2″ | 3-5/8″ |

| 1-3/4″ | 25 | 13.59 | 2-7/8″ | 2″ | 5-3/4″ | 1-3/4″ | 4-1/8″ |

| 2″ | 35 | 19.6 | 3-1/4″ | 2-1/4″ | 6-3/4″ | 2″ | 5″ |

| 2-1/2″ | 55 | 33.2 | 4-1/8″ | 2-3/4″ | 8″ | 2-1/2″ | 6″ |

| 3″ | 85 | 54 | 5″ | 3-1/4″ | 8-1/2″ | 3″ | 7-7/8″ |

Products Diagrams

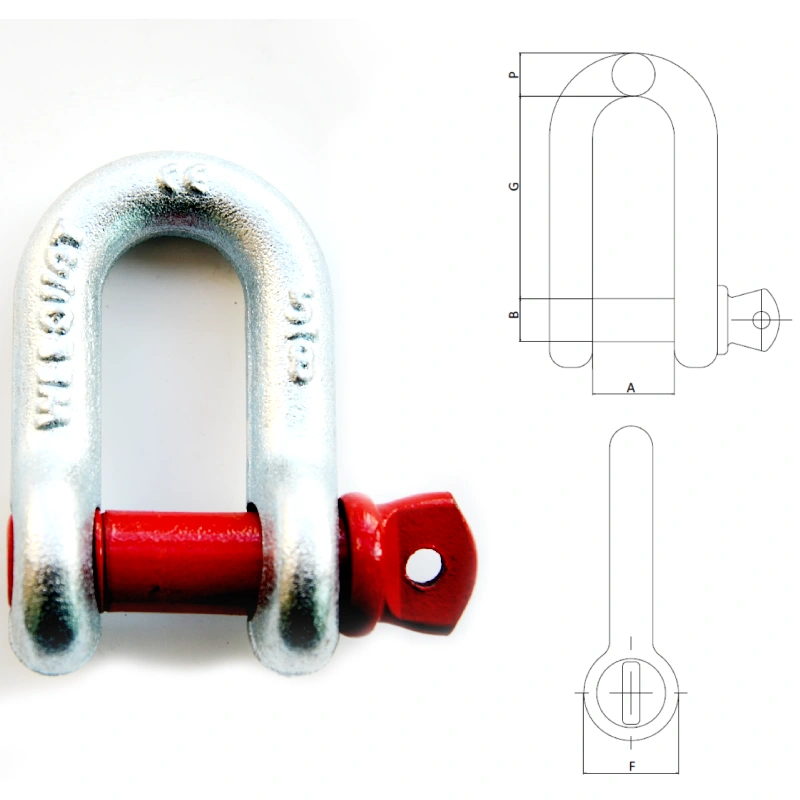

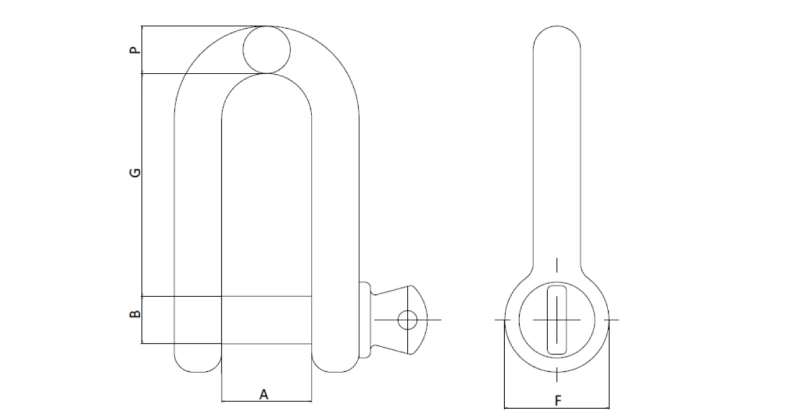

The G-210 Shackle’s “D” shape and screw pin assembly are clearly visible. Its compact body design ensures maximum strength for straight-line lifting applications.

The precision-threaded pin and smooth galvanized finish highlight its drop-forged construction, ensuring durability, easy handling, and reliable repeated use in the field.

Material Specification

Grade:

Complies with U.S. Federal Specification RR-C-271 Type IVA standards for rated load performance and consistent safety assurance.

Finish:

Available in hot-dip galvanized or electro-galvanized finishes to prevent corrosion and extend product lifespan.

Attachment:

Easily connects to chain, wire rope, or web sling for stable and secure straight-line lifting connections.

Hook Type:

Features a straight-sided “D” shape that maintains load alignment and reduces bending stress during vertical lifts.

Material:

High-tensile drop-forged carbon steel, heat-treated for superior mechanical strength and long-lasting performance.

Application

Construction Industry

Used in lifting beams, scaffolding, and rigging operations requiring stable vertical load control.

Marine & Offshore

Ideal for lifting and securing cargo, equipment, and anchors in coastal and offshore conditions.

Mining Industry

Perfect for hauling, equipment connections, and material handling where straight load application is required.

Advantages

Corrosion & Finish Protection

Heavy-duty galvanized coating resists rust and maintains surface integrity in outdoor and marine environments.

Customization & Traceability

Custom logo, batch code, and WLL marking available for OEM clients seeking traceability and brand consistency.

Load Control & Durability

Drop-forged structure provides high tensile strength and maintains straight-line load stability under heavy pressure.

Bulk Capacity & Lead Time

Strong production capacity supports large wholesale orders with efficient lead times and stable global supply.

What Our Clients Say

FAQ

What is the load capacity of your U.S. Type Drop Forged G-210 Screw Pin Dee Shackle?

Our G-210 Shackles meet U.S. Federal Specification RR-C-271 Type IVA standards with Working Load Limits (WLL) from 0.33T to 55T. Each unit is proof-tested, marked with WLL and batch code for traceability, ensuring safety in lifting and rigging applications.

Can these shackles be used for side loading or multi-leg sling applications?

No. G-210 Shackles are designed strictly for straight-line lifting. Using them with multi-leg slings can create side loading, leading to deformation or failure. For multi-leg applications, we recommend G-209 Anchor Shackles.

Do you offer OEM branding or customized packaging?

Yes. We provide OEM services with custom logo engraving, specific WLL markings, and private-label packaging. This helps distributors and large brands maintain consistent identity and product recognition.

What surface treatments do you offer?

We provide hot-dip galvanizing, electro-galvanizing, and powder coating for extra corrosion resistance. Each treatment is tested for adhesion and durability to suit different environments and climates.

How do I choose the correct shackle size for my setup?

Our engineers can assist you in selecting the right shackle size based on the rope, chain, or sling you’re using. Simply provide your working load and connection details, and we’ll recommend the proper match.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.