Product Specifications

| ROPE SIZE | WEIGHT PER 100(LBS.) | DIMENSIONS (IN.) | ||||||||

| (IN.) | (MM) | A | B | C | D | E | F | G | H | |

| 1/8″ | 3-4 | 6 | 0.22 | 0.72 | 0.44 | 0.47 | 0.37 | 0.38 | 0.81 | 0.99 |

| 3/16″ | 5 | 10 | 0.25 | 0.97 | 0.56 | 0.59 | 0.50 | 0.44 | 0.64 | 1.18 |

| 1/4″ | 6-7 | 19 | 0.31 | 1.03 | 0.50 | 0.75 | 0.66 | 0.56 | 1.19 | 1.43 |

| 5/16″ | 8 | 28 | 0.38 | 1.38 | 0.75 | 0.88 | 0.73 | 0.69 | 1.31 | 1.66 |

| 3/8″ | 9-10 | 48 | 0.44 | 1.5 | 0.75 | 1.00 | 0.91 | 0.75 | 1.63 | 1.94 |

| 7/16″ | 11 | 78 | 0.50 | 1.88 | 1.00 | 1.19 | 1.13 | 0.88 | 1.91 | 2.28 |

| 1/2″ | 12-13 | 8 | 0.50 | 1.88 | 1.00 | 1.19 | 1.13 | 0.88 | 1.91 | 2.28 |

| 9/16″ | 14-15 | 109 | 0.56 | 2.25 | 1.25 | 1.31 | 1.34 | 0.94 | 2.06 | 2.50 |

| 5/8″ | 16 | 110 | 0.56 | 2.25 | 1.25 | 1.31 | 1.34 | 0.94 | 2.06 | 2.50 |

| 3/4″ | 18-20 | 142 | 0.62 | 2.75 | 1.44 | 1.50 | 1.39 | 1.06 | 2.25 | 2.84 |

| 7/8″ | 22 | 212 | 0.75 | 3.12 | 1.62 | 1.75 | 1.58 | 1.25 | 2.44 | 3.16 |

| 1″ | 24-26 | 252 | 0.75 | 3.50 | 1.81 | 1.88 | 1.77 | 1.25 | 2.63 | 3.47 |

| 1-1/8″ | 28-30 | 283 | 0.75 | 3.88 | 2.00 | 2 | 1.91 | 1.25 | 2.81 | 3.59 |

| 1-1/4″ | 32-34 | 438 | 0.88 | 4.44 | 2.22 | 2.31 | 2.17 | 1.44 | 3.13 | 4.13 |

| 1-3/8″ | 36 | 442 | 0.88 | 4.44 | 2.22 | 2.38 | 2.31 | 1.44 | 3.13 | 4.19 |

| 1-1/2″ | 38 | 544 | 0.88 | 4.94 | 2.38 | 2.59 | 2.44 | 1.44 | 3.41 | 4.44 |

| 1-5/8 | 41-42 | 704 | 1.00 | 5.31 | 2.62 | 2.75 | 2.66 | 1.63 | 3.63 | 4.75 |

| 1-3/4″ | 44-46 | 934 | 1.13 | 5.75 | 2.75 | 3.06 | 2.92 | 1.81 | 3.81 | 5.24 |

| 2″ | 48-52 | 1300 | 1.25 | 6.44 | 3.00 | 3.38 | 3.28 | 2.00 | 4.44 | 5.88 |

| 2-1/4″ | 56-58 | 1600 | 1.25 | 7.13 | 3.19 | 3.88 | 3.19 | 2.00 | 4.56 | 6.38 |

| 2-1/2″ | 62-65 | 1900 | 1.25 | 7.69 | 3.44 | 4.13 | 3.69 | 2.00 | 4.05 | 6.63 |

| 2-3/4″ | 68-72 | 2300 | 1.25 | 8.31 | 3.56 | 4.38 | 4.88 | 2.00 | 5.00 | 6.88 |

| 3″ | 75-78 | 3100 | 1.50 | 9.19 | 3.88 | 4.75 | 4.44 | 2.38 | 5.31 | 7.61 |

| 3-1/2″ | 85-90 | 4000 | 1.50 | 10.75 | 4.50 | 5.50 | 6.00 | 2.38 | 6.19 | 8.38 |

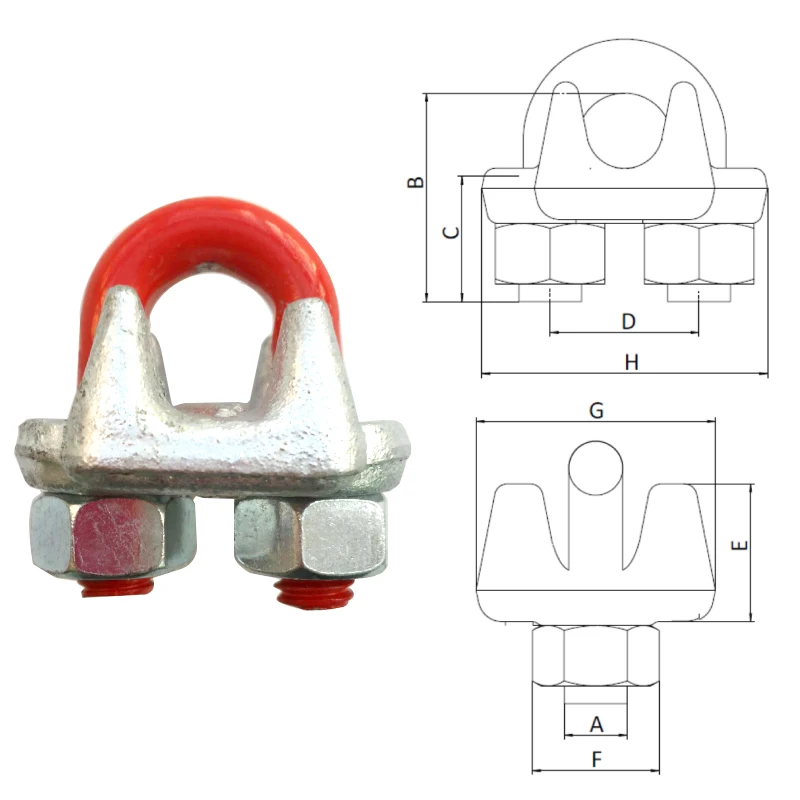

Products Diagrams

The G-450 Drop Forged Wire Rope Clip features a heavy-duty U-bolt and forged saddle design that maintains strong clamping force even under vibration or dynamic loads. Its precision threading ensures even pressure across the rope surface for optimal grip.

With its forged construction and smooth saddle curvature, this clip minimizes rope wear and slippage. It can be easily installed in both shop and field settings, ensuring quick assembly for large-scale projects.

Material Specification

Grade:

Manufactured from high-tensile drop-forged carbon steel to ensure exceptional strength and fatigue resistance under heavy load conditions.

Finish:

Hot-dip galvanized finish provides superior corrosion protection and extended service life in harsh weather and marine environments.

Attachment:

U-bolt with dual-threaded nuts and a forged saddle ensures a secure, vibration-resistant grip on wire ropes of various diameters.

US Type G-450 Drop Forged Wire Rope Clips Type:

Designed in accordance with U.S. Fed. Spec. FF-C-450 standards for precision, interchangeability, and safety compliance.

Material:

Forged carbon steel ensures uniform strength, structural integrity, and long-term reliability across a wide range of load-bearing applications.

Application

Construction Industry

Used in scaffolding, crane operations, and structural tension systems, providing safe and secure wire rope terminations on-site.

Marine & Offshore

Ideal for rigging, towing, and mooring operations where corrosion resistance and load stability are crucial.

Mining Industry

Applied in haulage systems and lifting assemblies, offering dependable strength and durability under high-impact working conditions.

Advantages

Corrosion & Finish Protection

Hot-dip galvanized coating ensures excellent rust resistance and long-term protection against harsh environmental exposure.

Customization & Traceability

Available in multiple sizes, finishes, and branding options with batch traceability for safety compliance and quality assurance.

Load Control & Durability

Drop-forged construction delivers high mechanical strength, ensuring secure load retention during vibration and tension stress.

Bulk Capacity & Lead Time

Mass production capability supports large-volume orders with consistent quality, short lead times, and competitive factory pricing.

What Our Clients Say

FAQ

What is a US Type G-450 Drop Forged Wire Rope Clip used for?

The G-450 wire rope clip is used to secure the end of a wire rope back to the standing part, forming loops or eyes. It’s commonly used in lifting, rigging, and material-handling systems where maximum load safety is required.

What makes G-450 clips different from malleable wire rope clips?

Unlike malleable clips, G-450 clips are drop forged, making them much stronger and more durable. They meet U.S. Federal standards for use in critical applications, including overhead lifting, where malleable clips are not recommended.

How should I install a G-450 wire rope clip correctly?

Place the U-bolt over the dead end of the rope and position the saddle on the live end. Tighten nuts evenly and use the recommended number of clips based on rope diameter. Retighten after load testing to ensure a firm grip.

What size clip should I select for my wire rope?

Match the clip size to the exact rope diameter. Incorrect sizing may cause slippage or reduce the rope’s breaking strength. Our technical team provides guidance and charts for precise selection.

Can I use G-450 clips in marine or outdoor environments?

Yes. The hot-dip galvanized finish protects against corrosion and oxidation, making these clips suitable for offshore, marine, and outdoor industrial conditions.

What is the standard lead time for bulk G-450 clip orders?

Standard sizes are ready for shipment within 7–10 business days. Custom orders, branding, or coatings may take 2–3 weeks depending on production load and order volume.

Are test certificates or quality documents available?

Yes. Each batch of G-450 clips comes with material certificates and load test documentation upon request, ensuring complete traceability and compliance with industry standards.

Why should distributors choose Powerful Machinery?

Powerful Machinery provides direct factory pricing, stable quality control, and full customization. With international export experience, we support OEM/ODM production and fast global delivery for wholesale and industrial buyers.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.