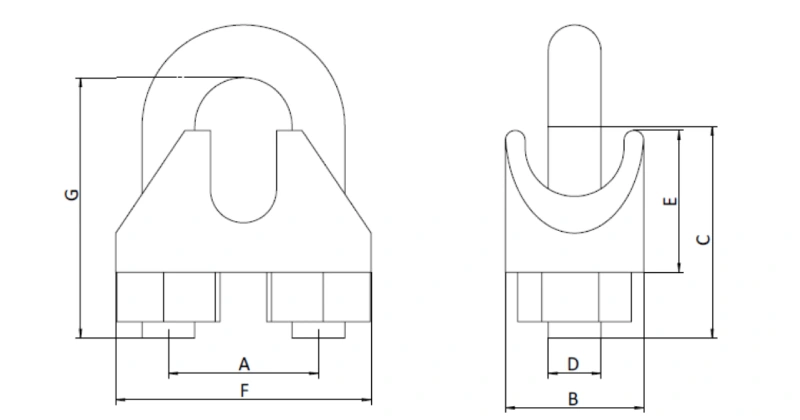

Product Specifications

| SIZE MM | A MM | B MM | C MM | D MM | E MM | F MM | G MM | W/100PCS KGS |

| 1/8 | 11 | 14 | 14 | 44 | 10.8 | 22 | 20 | 1.54 |

| 3/16 | 14.5 | 15 | 16 | 1/4 | 13 | 26 | 24 | 2.5 |

| 1/4 | 17 | 18.5 | 20 | 5/16 | 15 | 32 | 31 | 5.3 |

| 5/16 | 18.3 | 20 | 22 | 5/16 | 16 | 35 | 34 | 5.9 |

| 3/8 | 22.5 | 22 | 27 | 3/8 | 22 | 40.5 | 41 | 11 |

| 7/16 | 24 | 23 | 30 | 3/8 | 22 | 43 | 42 | 11 |

| 1/2 | 27 | 26 | 35 | 7/16 | 23.3 | 49 | 53 | 18.5 |

| 9/16 | 30 | 26.5 | 40 | 1/2 | 27 | 52.5 | 54 | 25 |

| 5/8 | 33 | 28 | 40 | 1/2 | 28 | 57.5 | 59 | 28 |

| 3/4 | 34.5 | 32 | 42 | 9/16 | 34 | 61 | 68 | 35 |

| 7/8 | 41 | 37 | 46 | 5/8 | 38 | 71 | 78 | 53 |

| 1 | 45.5 | 42 | 55 | 5/8 | 43 | 77.5 | 87 | 66.6 |

Products Diagrams

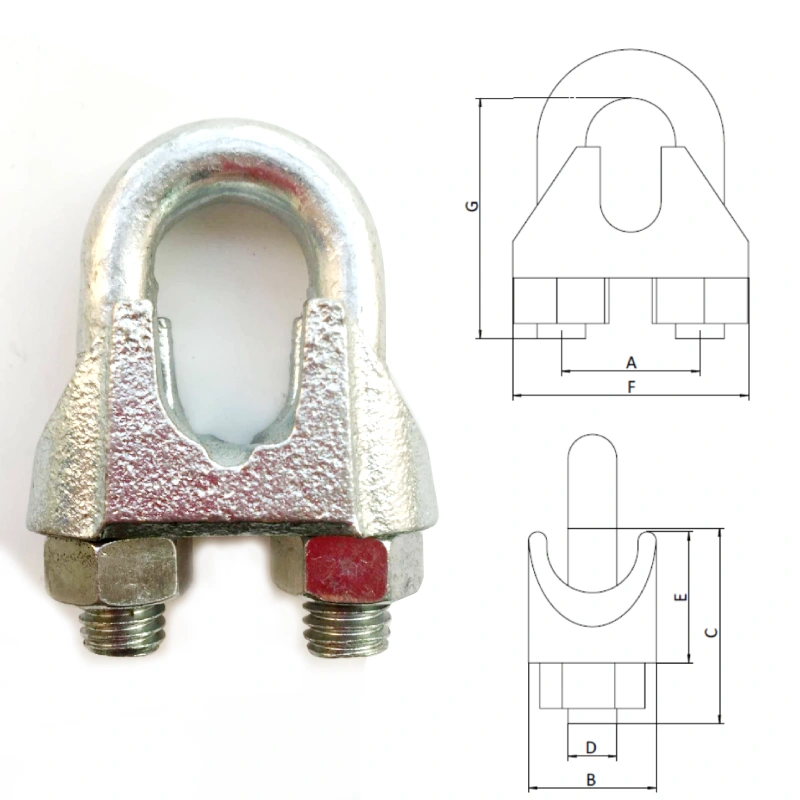

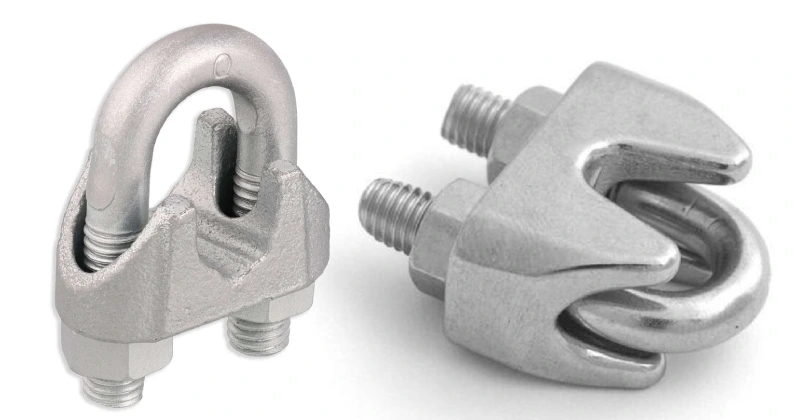

The US Type Malleable Wire Rope Clip consists of a U-bolt, saddle, and nuts, designed for simple clamping of wire rope ends. Its structure ensures quick installation, firm holding, and easy adjustment, making it ideal for non-lifting applications where strength and convenience are equally important.

Available in a full range of diameters, each clip is precisely machined for consistent fit with various wire rope sizes. The hot-dip galvanized or electro-galvanized surface provides a smooth finish that resists corrosion and extends service life, even in demanding outdoor or marine conditions.

Material Specification

Grade:

Manufactured from high-quality malleable iron conforming to US industrial standards. This ensures flexibility, toughness, and reliable performance under light to medium tension loads.

Finish:

Available in zinc-plated or hot-dip galvanized finishes to enhance corrosion protection and aesthetic appearance for long-term outdoor use.

Attachment:

Designed with a U-bolt and saddle secured by heavy-duty nuts, providing easy tightening and safe wire rope connection without slippage.

Type:

Standard US Type design ensures universal compatibility with wire ropes in construction, agriculture, and marine maintenance applications.

Material:

Forged malleable iron body and carbon steel fasteners combine strength, resilience, and cost efficiency for reliable fastening solutions.

Application

Construction Industry

Used for securing temporary structures, scaffolding, and fencing lines, offering dependable wire rope connection and simple on-site assembly in construction environments.

Marine & Offshore

Ideal for boat rigging, mooring lines, and non-critical deck applications where corrosion resistance and long-term reliability are essential.

Mining Industry

Applied in securing safety barriers, cable guides, and temporary support lines, providing quick fastening and adjustment in rugged mining conditions.

Advantages

Corrosion & Finish Protection

Galvanized surface provides long-lasting resistance to moisture, rust, and environmental wear, ensuring dependable performance even in marine and outdoor applications.

Customization & Traceability

OEM options include logo engraving, packaging, and surface treatment, with full batch traceability for industrial buyers and distributors.

Load Control & Durability

Engineered for reliable clamping strength under consistent tension, maintaining secure grip and alignment of wire rope ends over time.

Bulk Capacity & Lead Time

Automated production ensures stable supply, competitive factory pricing, and efficient lead times to meet large-scale project or wholesale demands.

What Our Clients Say

FAQ

What is a US Type Malleable Wire Rope Clip used for?

It’s primarily used for securing the ends of wire ropes in fencing, handrails, and general-purpose clamping. Designed for non-lifting tasks, it provides strong grip and easy installation where overhead safety is not a concern.

What makes Powerful Machinery’s wire rope clips reliable?

We manufacture each clip using malleable iron under strict quality control. Every piece is galvanized for corrosion resistance and inspected for dimensional accuracy before packing and shipment.

Can I order customized sizes or packaging?

Yes. We provide full OEM customization including logo engraving, special coatings, and packaging to support distributors, contractors, and large-scale industrial projects.

How should I install the wire rope clip correctly?

Ensure the saddle is placed on the live end of the rope and the U-bolt on the dead end. Tighten nuts evenly and recheck tension after initial use.

Are test certificates available with shipments?

Yes. We supply material test certificates (MTC), compliance documentation, and inspection reports for every order to ensure transparency and quality assurance.

What’s your production lead time for bulk orders?

Standard orders ship within 15–20 days. Custom or large-volume orders are processed efficiently through automated forging and finishing systems.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.