WIRE PULLING GRIPS SPECIFICATIONS

| Model | Cable Diameter -mm- | Breaking Strength -Lbs. | E | M | Rotating Eye Dia -Inches. |

| SHORT | |||||

| KG-050A | 12-15 | 5,600 | 5 | 11 | 7/8 |

| KG-062A | 15-18 | 6,800 | 5 | 11 | 7/8 |

| KG-075A | 18-25 | 6,800 | 6 | 20 | 1 |

| KG-100M | 25-37 | 12,800 | 7 | 20 | 1-3/8 |

| KG-150M | 37-50 | 16,400 | 7 | 25 | 1-3/8 |

| KG-200M | 50-63 | 27,200 | 8 | 26 | 1-3/8 |

| KG-225M | 63-75 | 33,000 | 10 | 28 | 1-5/8 |

| KG-300M | 75-88 | 41,000 | 10 | 30 | 1-7/8 |

| KG-350M | 88-101 | 48,000 | 10 | 32 | 1-7/8 |

| KG-400M | 101-114 | 50,000 | 10 | 34 | 1-7/8 |

| KG-450M | 114-127 | 52,000 | 10 | 36 | 1-7/8 |

| KG-500M | 127-152 | 54,000 | 10 | 38 | 1-7/8 |

| KG-600M | 152-177 | 56,000 | 10 | 40 | 1-7/8 |

| STANDARD | |||||

| KG-050M | 12-15 | 5,600 | 5 | 16 | 7/8 |

| KG-062M | 15-18 | 6,800 | 5 | 16 | 7/8 |

| KG-075P | 18-25 | 9,600 | 6 | 32 | 1 |

| KG-100P | 25-37 | 16,400 | 7 | 33 | 1-3/8 |

| KG-125P | 37-50 | 16,400 | 7 | 34 | 1-3/8 |

| KG-150P | 50-63 | 27,200 | 9 | 36 | 1-5/8 |

| KG-250P | 63-75 | 33,000 | 10 | 38 | 1-7/8 |

| KG-300P | 75-88 | 41,000 | 10 | 39 | 1-7/8 |

| KG-350P | 88-101 | 48,000 | 10 | 41 | 1-7/8 |

| KG-400P | 101-114 | 48,000 | 10 | 42 | 1-7/8 |

| KG-450L | 114-127 | 48,000 | 10 | 58 | 1-7/8 |

| KG-500L | 127-152 | 48,000 | 10 | 60 | 1-7/8 |

| KG-600L | 152-177 | 48,000 | 10 | 66 | 1-7/8 |

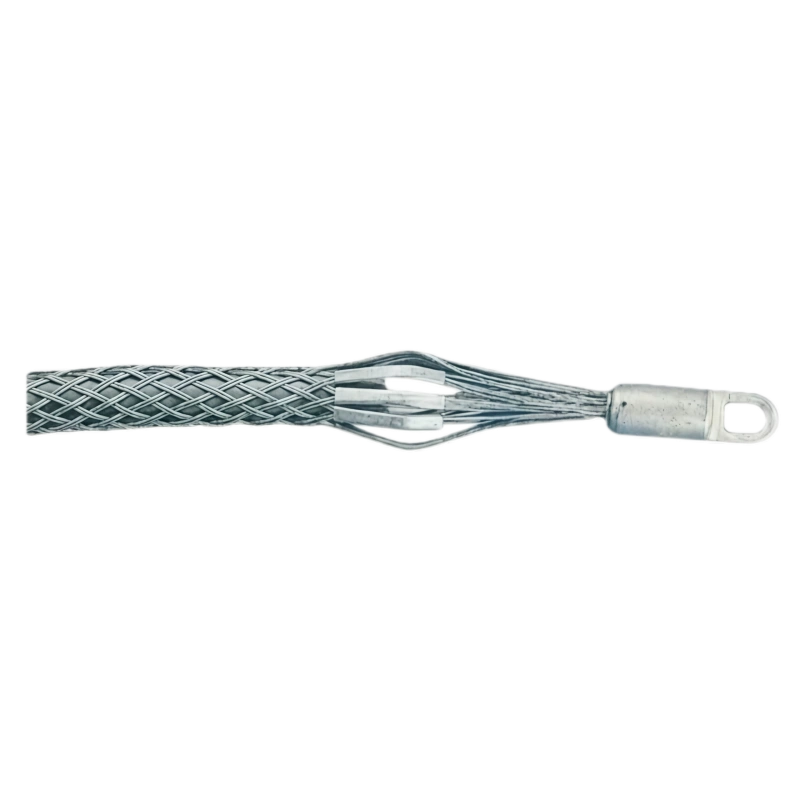

FEATURES OF PULLING GRIPS FOR WIRE

KG Type: Suitable for heavy-duty cable handling.

Rotating Head (Non-Swivel): Provides secure grip, though not a swivel.

Double-Weave Construction: Ensures enhanced durability and strength.

Rotating-Eye Design: Allows for smoother cable handling.

Use with Swivel: Improves rotation for easier cable pulls.

INSTRUCTIONS & CAUTIONS

Check Load Capacity

Always verify that the weight of the cable does not exceed the load limits of the wire pulling grip. While it’s designed for heavy-duty cable, overloading can damage the grip and jeopardize safety. Ensure you’re using the grip within its recommended capacity for optimal performance.

Avoid Excessive Stretching

Do not overstretch the wire pulling grip. Overstretching can weaken its fibers and reduce its effectiveness. Make sure there’s enough slack in the cable and avoid pulling at sharp angles that could put unnecessary stress on the grip.

Use a Swivel for Smooth Rotation

The wire pulling grip features a rotating head, but it is not a swivel. To improve rotation and reduce friction during the pull, always use the grip in combination with a swivel. This simple addition helps ensure smoother operation and protects the grip from wear.

Inspect Regularly for Wear and Tear

Routine inspections are crucial for ensuring the longevity and safety of your wire pulling grip. Check for signs of damage or fraying before each use. If the grip shows any wear, it’s time to replace it to avoid potential failures during cable pulls.

OUR ADVANTAGES

Custom Solutions Tailored to You

No two businesses are the same, which is why we provide custom-engineered solutions. Whether you're working on a special project or have unique specifications, our team is ready to design and deliver exactly what you need. This ensures that the equipment you get is the best fit for your application, helping you get the most value.

Your One-Stop Sourcing Solution

We simplify your sourcing process by offering a wide range of lifting equipment and accessories in one place. From off-the-shelf products to custom solutions, we help you find exactly what you need. This efficient approach saves you time and effort, allowing you to meet your business needs quickly and smoothly.

Unmatched Quality and Safety

At Powerful Machinery, we focus on providing top-notch quality and safety across all our products. We carry out thorough quality checks to ensure each item meets strict standards. With carefully selected materials and advanced technology, our equipment delivers reliable performance, giving you peace of mind that it’s built to last, no matter the task.

Dedicated After-Sales Service

At Powerful Machinery, our commitment to service doesn’t stop when your order is delivered. We offer comprehensive after-sales support to ensure your equipment keeps performing at its best. From troubleshooting to training, our team is always available to help you maintain and optimize your equipment, making sure you’re set up for long-term success.

FAQ

How to Use Wire Pulling Grips?

Place the Grip Around the Cable

Position the wire pulling grip around the cable, ensuring the teeth of the grip securely hold the cable in place.Attach the Grip’s Eye to the Pulling System

Connect the grip’s eye to your pulling system, such as a winch or hoist, making sure it’s properly aligned for a secure pull.Check the Cable’s Alignment

Before pulling, verify that the cable is aligned correctly to avoid unnecessary friction and ensure smooth operation during the pull.Verify the Grip’s Load Capacity

Always check the wire pulling grip’s load capacity to ensure it can handle the weight of the cable. This step is crucial to prevent accidents and ensure safe, efficient use.

Can wire pulling grips be used for different cable sizes?

Yes, wire pulling grips are designed to handle a variety of cable sizes. However, it’s important to choose the right size grip for your cable to ensure a secure fit. Using a grip that’s too large or too small can lead to slippage or damage. Be sure to check the product specifications for the correct size and cable compatibility for optimal results.

How do I determine the correct wire pulling grip for my job?

Consider the Cable Type, Size, and Weight

Select a wire pulling grip based on the type, size, and weight of the cable you’ll be handling. Ensure the grip is designed to handle the specific cable you’re working with.Match the Grip’s Capacity with Your Cable’s Load

Verify that the grip’s load capacity is suitable for the weight and diameter of your cable. This ensures safe and efficient operation.Assess Environmental Factors

Take into account whether you’ll be working indoors, outdoors, or in rough conditions. Environmental factors can affect the grip’s performance and durability.Check the Manufacturer’s Guidelines

Always review the manufacturer’s guidelines for the recommended size, load capacity, and cable compatibility to ensure the grip is the right fit for your project.

How do I maintain a wire pulling grip?

Store in a Dry Place

Keep the wire pulling grip in a dry area to prevent moisture exposure, which can cause rust and corrosion.Clean After Each Use

Wipe off any dirt or debris after using the grip to maintain its performance and prevent build-up that can cause wear.Inspect for Damage

Regularly check the grip for any signs of damage, such as fraying or bent wires. Replace the grip if any damage is found.Apply Protective Oil in Harsh Environments

If the grip is used in rough conditions, apply a light coat of protective oil to help prevent corrosion and extend its life.Perform Regular Inspections

Conduct regular checks to ensure the grip is in good working condition, preventing issues before they arise and ensuring safe operation.

How do I choose between manual and electric pulling systems when using a wire pulling grip?

The choice between manual and electric pulling systems depends on your specific needs. Manual systems work well for smaller or less frequent cable pulls, while electric systems are faster and more efficient for larger or frequent tasks. When using a wire pulling grip with an electric system, ensure that the system is rated to handle the load for optimal safety and performance.

Are there any alternatives to wire pulling grips?

While wire pulling grips are a popular and effective choice, alternatives like cable socks, chain hoists, or cable rollers may also be used, depending on the application. However, wire pulling grips provide a superior level of security and control, especially for heavy-duty cables. If you’re handling large, tough cables, a grip will give you more stability and confidence in your pull.

What should I do if my wire pulling grip is damaged?

If your wire pulling grip is damaged, replace it immediately to avoid potential failure. Check for signs of damage such as fraying, corrosion, or broken strands. Continuing to use a damaged grip can be unsafe and may lead to accidents or equipment failure. Always inspect your grips after each use and replace any that show significant wear.