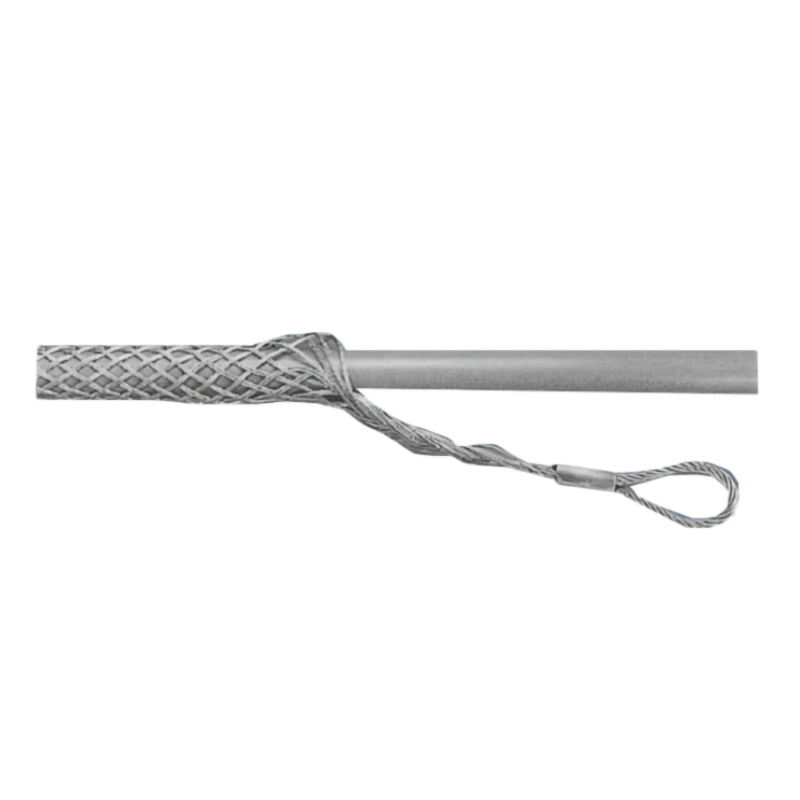

WIRE PULLING SOCK SPECIFICATIONS

| DOUBLE WEAVE | ||||

| Model | Cable Diameter -mm- | Breaking Strength -Lbs. | E | M |

| SG-075A | 18-25 | 2,500 | 7 | 9 |

| SG-100A | 25-32 | 3,500 | 8 | 10 |

| SG-125A | 32-37 | 4,000 | 8 | 10 |

| SG-150A | 37-50 | 4,000 | 9 | 17 |

| SG-200A | 50-63 | 4,000 | 10 | 18 |

| SG-250A | 63-75 | 4,000 | 10 | 19 |

| SG-300A | 75-88 | 4,000 | 12 | 21 |

| SG-300A | 88-101 | 4,000 | 12 | 22 |

| SG-400A | 101-114 | 4,800 | 12 | 23 |

| SG-450A | 114-127 | 5,000 | 12 | 24 |

| SG-500A | 127-152 | 5,200 | 12 | 25 |

| SG-600A | 152-177 | 5,400 | 12 | 26 |

FEATURES OF WIRE PULL SOCK

-

Split Mesh Design: Offers flexibility and secure grip for a wide range of cable diameters.

-

Lace Closing System: Ensures a tight and secure fit, adapting to various cable types and sizes.

-

Double Weave Construction: Adds durability, providing strength to handle high load conditions.

-

Ideal for Tight Spaces: Perfect for applications where cable ends are difficult to reach.

-

Superior Load Handling: Trusted for its performance under pressure, ideal for heavy-duty cable pulls.

-

Versatile Application: Suited for electrical contractors, industrial setups, and large infrastructure projects.

INSTRUCTIONS & CAUTIONS

Ensure a Secure Fit Around the Cable

Always make sure the wire pulling sock fits snugly around your cable. The mesh should be tightly gripped to prevent slippage during the pull. If the sock isn’t securely fastened, it can cause unnecessary stress on the cable and sock, affecting performance. A proper fit is essential for a smooth and efficient cable pull.

Match the Sock to Your Cable's Load and Size

Before using the sock, check that its load capacity aligns with the weight and diameter of your cable. Using a sock that’s too small or not rated for the cable’s weight can lead to failure or damage. Always refer to the manufacturer’s specifications to ensure compatibility. Choosing the correct sock guarantees safe, reliable cable handling.

Check Cable Alignment Before Pulling

Proper cable alignment is crucial for a smooth pull. Ensure there are no obstructions or twists in the cable before you begin. Misalignment can lead to uneven tension or damage to the wire pulling sock. When working in tight spaces, take extra care to avoid kinks or obstacles that could affect the pull.

Inspect the Sock for Damage After Each Use

After every use, inspect your wire pulling sock for signs of wear and tear, such as frayed edges or bent mesh. If any damage is found, replace the sock immediately. A damaged sock can lead to unsafe conditions and increase the risk of accidents. Regular inspections will keep your equipment in top working condition and prevent costly delays.

OUR ADVANTAGES

Custom Solutions Tailored to Your Needs

No two projects are the same, so we provide custom-engineered solutions designed to fit your unique requirements. Whether you need specific modifications or special designs, our team collaborates closely with you to deliver a solution that meets your exact needs. When you choose Powerful Machinery, you're getting a product built specifically for your business.

One-Stop Sourcing for Convenience

Save time and hassle with our one-stop sourcing solution. We offer a wide variety of lifting equipment and accessories, all in one place. Whether you need bulk orders or specialized products, our streamlined process ensures you get exactly what you need quickly and efficiently, with no need to go through multiple suppliers.

Top-Notch Quality & Safety Standards

We prioritize the highest quality and safety standards in every product we manufacture. Rigorous quality checks ensure our equipment meets industry standards, providing you with reliable and durable lifting solutions. With Powerful Machinery, you can trust that your equipment is built to last and perform safely in demanding environments.

Efficient Logistics & Competitive Pricing

We understand the importance of fast delivery. Our efficient logistics network ensures your orders arrive on time, every time, minimizing any potential downtime. With competitive pricing, we offer cost-effective solutions without sacrificing quality. You get reliable products, timely service, and the best value for your investment.

FAQ

What is a wire pulling sock?

A wire pulling sock is a tool designed to assist in pulling cables with ease. Its mesh construction securely grips the cable to prevent slipping, ensuring smoother, safer pulls. The sock is ideal for electrical contractors and industrial setups, providing flexibility and support when managing cable installations, maintenance, or upgrades in tight or hard-to-reach spaces.

How does a wire pulling sock work?

Wire pulling socks use a flexible, durable mesh that grips tightly around your cable, preventing any slippage during the pull. Once the sock is secured around the cable, you attach the sock’s eye to your pulling system (winch, hoist, etc.). The sock reduces friction, allowing for a smoother and more efficient cable pull, reducing the risk of damage during the process.

How do I choose the right size wire pulling sock?

-

Measure Your Cable’s Diameter and Weight

Start by measuring the diameter and weight of the cable you’ll be pulling. These measurements are crucial for selecting the right sock that will securely grip your cable. -

Match with Sock’s Size and Load Capacity

Refer to the sock’s specifications to ensure it can accommodate your cable’s size and weight. Ensure the sock’s load capacity matches the weight of your cable for safe handling. -

Ensure a Snug Fit

A snug fit is essential for efficient pulling. A sock that is too loose or too tight can lead to slippage or insufficient grip, causing damage to the cable or compromising safety. -

Refer to Manufacturer Specifications

Always check the manufacturer’s guidelines for the most accurate fit. Following these specifications helps ensure the sock provides optimal performance during the cable pull.

How do I use a wire pulling sock?

-

Slip the Sock Over Your Cable

Begin by slipping the wire pulling sock over your cable, ensuring that the mesh grips the cable tightly. The sock should cover the cable completely for a secure hold. -

Attach the Sock’s Eye to Your Pulling System

Once the sock is in place, attach the sock’s eye to your pulling system, such as a hoist or winch. Make sure the connection is secure and stable before beginning. -

Align the Cable Properly

Ensure the cable is properly aligned and free from obstructions. This step is crucial for a smooth and efficient pull, reducing the risk of damage or interruption. -

Verify Load Capacity

Before starting the pull, double-check that the sock’s load capacity matches your cable’s weight. This ensures the sock can handle the pull without risk of failure, ensuring a safe and smooth operation.

How do I maintain a wire pulling sock?

-

Store in a Dry, Cool Place

Always store your wire pulling sock in a dry and cool environment. Avoid areas with high humidity or extreme temperatures that could damage the material. -

Clean After Each Use

After each use, wipe off any dirt or debris. If necessary, wash the sock with mild detergent and water to remove built-up residue. -

Inspect for Damage Regularly

Periodically check your sock for any signs of fraying or broken mesh. These can compromise the sock’s performance, so it’s important to address any damage promptly. -

Replace Damaged Socks

If you notice any significant damage, such as frayed edges or a broken mesh, replace the sock immediately. This ensures safe and reliable performance during future use.