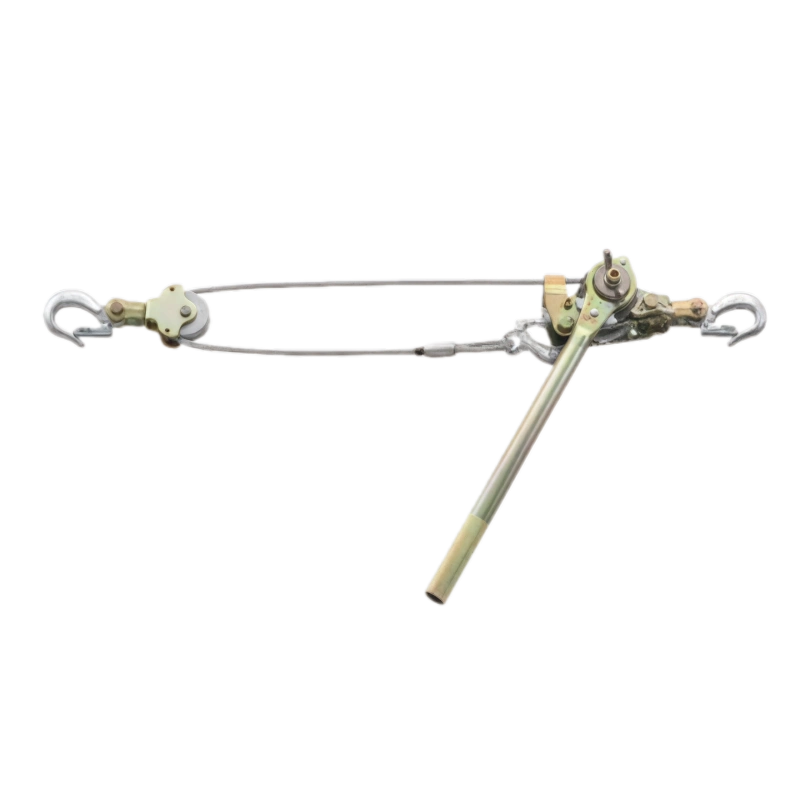

WIRE ROPE HAND RATCHET PULLER FEATURES

Versatile Applications: Effective for lifting, tensioning, and securing cables and equipment.

Multiple Models: Available in hand chain hoist, ratchet tightener, and double hook puller designs.

Heavy-Duty Construction: Steel and aluminum options to handle varying load capacities.

Improved Safety: Tightening mechanism enhances safety in transportation and lifting.

Simple Operation: Easy-to-use design with wire clamps and a dedicated wrench for precise tensioning.

INSTRUCTIONS & CAUTIONS

Ensure Proper Setup

Before using the wire rope ratchet puller, make sure it’s securely attached to a stable anchor point. Ensure the wire rope is properly connected to avoid slippage or accidents during operation. An improper setup can lead to damage to the tool or, worse, injuries.

Verify Load Capacity

Always check the load weight before use. Each wire rope ratchet puller has a specific weight limit, and exceeding that limit could damage the equipment or cause operational failure. Stick to the manufacturer’s recommended specifications for safety and optimal performance.

Operate Slowly and Carefully

Avoid sudden movements when using the ratchet puller. Apply steady, controlled force to ensure smooth and consistent tensioning. Abrupt actions can cause the wire rope to snap or damage the equipment, increasing the risk of accidents.

Regular Maintenance Checks

Inspect the wire rope ratchet puller regularly to ensure it’s in good working condition. Check for any wear on the wire rope, hooks, or ratchet mechanism. If you notice any damage, halt operation immediately and replace or repair parts as needed to maintain safety.

OUR ADVANTAGES

Custom Solutions Designed for You

We know that every project has unique demands. That’s why we provide custom-engineered solutions designed specifically for your operation. Our team works closely with you to create equipment that matches your exact requirements, ensuring you get the most out of your investment and maximizing operational efficiency.

One-Stop Sourcing for Convenience

With Powerful Machinery, you can find everything you need in one place. We offer a broad range of lifting equipment, including standard products and custom-engineered solutions tailored to your exact needs. This simplifies your procurement process, saving you time and making your sourcing much more efficient.

Commitment to Quality and Safety

We take quality and safety seriously at Powerful Machinery. Every product is thoroughly inspected to meet high industry standards, ensuring it performs reliably under tough conditions. By using only carefully selected materials, we make sure our equipment delivers long-lasting durability and safety in every lift.

Efficient Logistics & Competitive Pricing

Our logistics network is built for speed and reliability, ensuring your orders are delivered when you need them. By optimizing our supply chain, we keep costs low, which means you can count on competitive pricing without sacrificing quality. With Powerful Machinery, you get excellent value and top-tier performance.

FAQ

How do I use a ratchet cable puller?

Secure the Wire Rope

Attach one end of the wire rope to a stable anchor point to ensure it’s securely in place.Connect to the Load

Attach the other end of the rope to the load you wish to pull or tension.Engage the Ratchet Mechanism

Turn the handle to engage the ratchet mechanism. This will begin pulling the rope gradually.Pull Gradually

Continue pulling the rope until you achieve the desired tension. Do this slowly and steadily for better control.Stay Within Load Capacity

Always ensure the puller is within its rated load capacity to prevent damage to the tool and ensure safe operation.

How do I know if my ratchet puller is the right size for the job?

Check Load Capacity

Verify that the puller’s load capacity can handle the weight and tension of your load. Always match the puller’s rating to your specific needs.Consider Rope Length

Ensure the length of the wire rope is sufficient for the distance you need to cover. Longer distances require a puller with a longer rope.Review Manufacturer’s Specifications

Refer to the puller’s specifications to ensure it is the correct size for your job. Manufacturer guidelines will provide the most accurate information.Assess Load and Tension Requirements

Double-check that the puller can manage both the load weight and the tension needed for the task, ensuring it is suitable for safe operation.

Can I use a wire rope ratchet puller for non-linear pulling?

Yes, with the proper setup, a wire rope ratchet puller can be used for non-linear pulling. Using accessories like cable clamps can help direct the force in different angles. This flexibility makes the puller ideal for various tasks where the load isn’t directly in line with the puller.

How do I prevent damage to the wire rope during use?

Inspect the Rope Before Use

Check the wire rope for fraying, kinks, or any signs of wear before each use. This ensures you catch potential issues early.Avoid Rough or Sharp Surfaces

Do not pull the rope across rough or sharp surfaces that could cause abrasion or cuts. Protect the rope from damaging contact.Replace Worn Rope Immediately

If you notice any damage, replace the rope immediately to avoid failure during operation and ensure safety.Practice Proper Care

Handle the rope with care during use and storage. Proper maintenance extends the life of the rope and helps the puller perform reliably.

What should I do if the wire rope ratchet puller is not working properly?

If your ratchet puller isn’t working, check for obstructions in the mechanism, or inspect the rope for damage. Clean and lubricate the moving parts, and check that the ratchet mechanism is functioning smoothly. If the issue persists, consult the user manual or contact the manufacturer for assistance.

Can a wire rope ratchet puller be used for replacing insulators in transmission lines?

Yes, wire rope ratchet pullers are commonly used in transmission line maintenance, including insulator replacement. They help adjust the tension on cables, making it easier to install or replace components like insulators. Always ensure the puller is suited for the specific tasks involved.