As a trusted manufacturer of double leg chain slings, we specialize in creating custom lifting solutions for both small and oversized applications. Our focus is on delivering high-quality chains with strength-enhancing features such as triple alloy (nickel, chromium, molybdenum) and single-weld links, ensuring maximum durability and safety.

When ordering a custom double leg chain sling, please keep the following in mind:

-

SIZE: This is based on the material size of the chain, determined by the required working load limit.

-

REACH: Measured from bearing point to bearing point, including all attachments.

-

ATTACHMENTS: Standard master links will be used unless otherwise specified. If you require non-standard master links or hooks, please provide a complete description or drawing of the requested substitute.

-

TYPE: Choose and specify the appropriate sling type, such as:

-

D = Double Leg

-

O = Oblong Link

-

S = Sling Hook (if applicable)

-

These specifications ensure your double leg chain sling is customized to meet your exact needs, providing the safety, strength, and reliability required for efficient lifting operations.

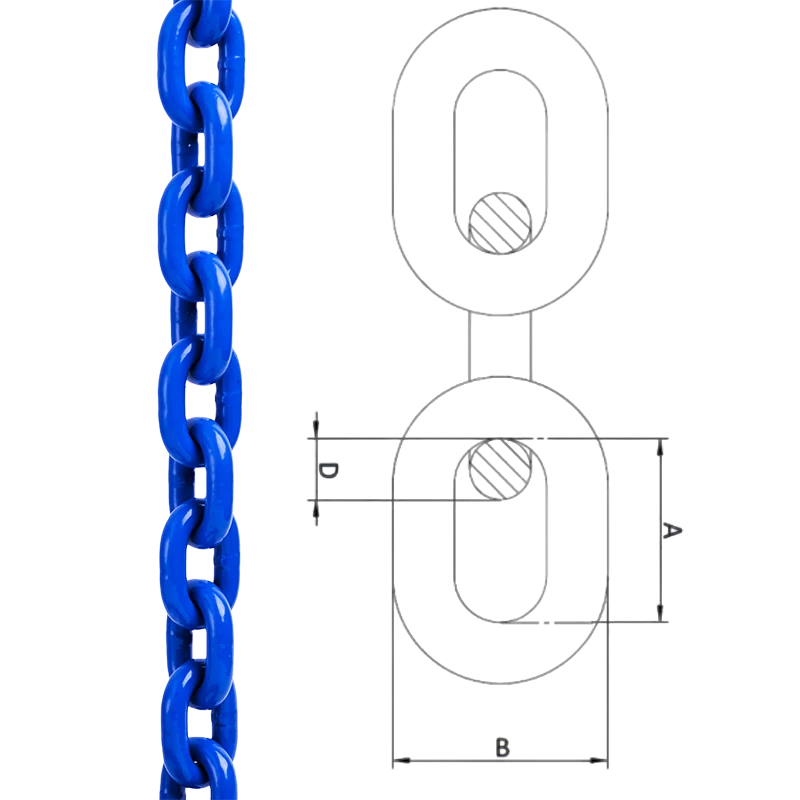

DESIGN of DOUBLE LEG CHAIN SLING

GRADE

- 100

FINISH

- Blue Powder Coat Finish

STANDARDS

- Meets or exceeds ASTM A952, NACM, & OSHA 910 Standards

- Safety factor 4:1

- Fatigue Tested at 1.5 times the WLL for 20,000 cycles

- Proof Tested at twice the WLL

HEAT TREATMENT

- Quenched and tempered before proof testing

ORIGIN

- Made in China

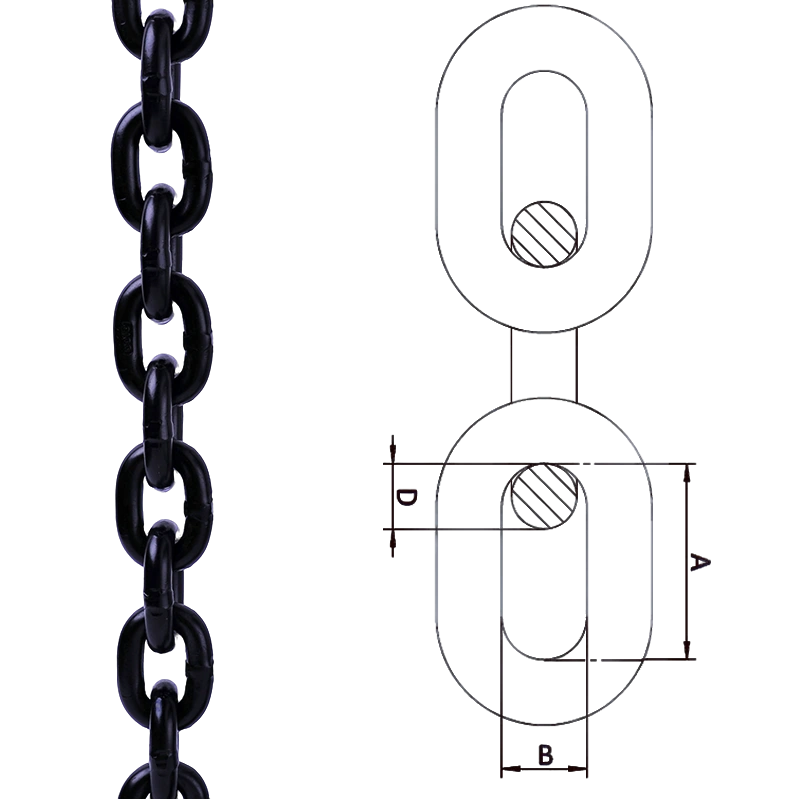

LINK TYPE

- Master Link

APPLICATION

- For overhead lifting

- Suited for use with wire rope, chain, and slings

MATERIAL

- Premium Fine Grain Alloy Steel

FAQ of TWO LEG CHAIN SLING

What is a 2 leg chain sling and how does it differ from other lifting slings?

Understanding 2 leg chain slings helps you choose the right lifting solution for construction, manufacturing, and heavy-duty operations. Here’s what you need to know:

Dual-leg design: Features two chain legs connected to a master link at the top and hooks at the bottom for stable lifting points.

Load balance: Two legs distribute weight evenly, reduce swinging, and handle asymmetrical or wide loads better than single-leg slings.

Versatile lifting: Ideal for beams, engines, containers, and awkward equipment without twisting the load.

Stress reduction: Lowers stress on lifting points and increases overall stability, giving you safer, more controlled lifts compared to single-leg solutions.

How do you determine 2 leg chain sling capacity?

Knowing the correct capacity of a 2 leg chain sling ensures safe lifting and prevents equipment damage. Here’s how to determine it accurately:

Chain diameter and grade: Larger diameters and higher grades (like Grade 80 or 100) increase lifting capacity.

Leg angle: Narrower included angles between legs reduce capacity, while wider angles allow heavier lifts safely.

Load distribution: Evenly spreading the load across both legs maximizes strength and minimizes stress.

WLL charts: Use manufacturer charts to verify working load limits for specific chain sizes, grades, and angles.

Practical example: A 13 mm Grade 80 chain can lift about 7.5 tonnes at standard angles; larger chains handle more weight.

How much does a 2 leg chain sling weigh?

Weight varies with chain diameter and grade because thicker, higher grade steel adds mass. Manufacturers supply detailed weight data for each sling assembly based on diameter and overall length. When planning lifts or ordering, specify hook types, leg lengths, and chain grade so we can provide precise weights that factor into rigging equipment load and transport planning.

What does chain sling grade mean and why is it important?

Chain grade denotes the strength and heat treatment of alloy steel chain. Common grades for lifting include Grade 80, Grade 100 and higher grades like Grade 120. Higher grades mean stronger chain with a better strength‑to‑weight ratio, so a Grade 100 sling can lift a given weight with smaller chain size and less weight than a Grade 80 equivalent. Choosing the right grade optimizes sling performance and reduces rigging bulk.

How do you inspect a 2 leg chain sling before use?

Regular inspections keep your 2 leg chain slings safe and reliable. Follow these steps before every lift to prevent accidents and ensure compliance:

Check chain links: Look for bent, cracked, stretched, corroded, or worn links.

Examine hooks: Inspect for deformations, sharp nicks, or damage that could compromise lifting.

Verify tags: Ensure load rating tags are legible and match the sling specifications.

Qualified inspections: Assign trained personnel for detailed inspections at least once a year or more often in harsh conditions.

Record keeping: Maintain inspection logs and remove damaged slings immediately; repair or replace only with certified components.

How do angles between legs affect lifting capacity?

The included angle between the two legs dramatically affects load distribution. Smaller angles (closer to vertical) keep more load on each leg, while wider angles reduce effective capacity because forces multiply. Your rigging plan should maintain angles within recommended limits, and you should use manufacturer capacity charts that factor angle effects to avoid overloading any component.

How should 2 leg chain slings be stored to maintain safety?

Proper storage of 2 leg chain slings extends their lifespan and ensures safe lifting. Follow these best practices to maintain sling integrity:

Clean, dry area: Keep slings away from moisture and corrosive chemicals that can cause rust or damage heat treatment.

Off the floor: Hang slings to prevent chain deformation and tangling.

Tagging: Keep slings tagged with inspection dates for easy tracking.

Environmental protection: Avoid exposure to harsh conditions that could weaken chains or reduce lifespan.

Maintenance: Proper storage reduces early replacement and maintains safe lifting performance.

How do you choose end fittings for a 2 leg chain sling?

End fittings like self‑locking hooks, sling hooks with safety catches, clevis hooks or oblong master links should match your lifting hardware and application. Self‑locking hooks secure under load and help avoid accidental release, while specialized fittings support unique rigging setups. Specify hook type, latch style, and opening size when ordering to ensure the sling integrates smoothly with your lifting gear.

Can 2 leg chain slings be custom made?

Yes, we can custom build slings to your required leg lengths, chain grade, hook type, and lifting configuration. Custom slings help optimize lift setups, reduce rigging time, and ensure balanced loads. Work with us to define your load profiles and environmental needs so they can tailor slings that improve performance and safety.

How often should periodic professional inspections occur?

Beyond daily pre‑use inspections, schedule professional inspections at least annually, more frequently under harsh conditions such as high‑temperature environments or repeated heavy lifts. A trained inspector can identify subtle defects that everyday users might miss, helping you prevent accidents and costly downtime.

How Do You Calculate Load Capacity for Uneven Loads?

For uneven loads where weight shifts between legs, carefully assess weight distribution and use capacity derating factors. Adjustable chain slings with shortening hooks help balance uneven loads. If uncertainty exists, consult manufacturer engineers or rigging specialists to verify safe working load requirements.