As a trusted manufacturer of 4 leg chain slings, we specialize in custom lifting solutions, from small-scale to heavy-duty applications. We focus on providing high-quality chains with strength-enhancing features, such as triple alloy (nickel, chromium, molybdenum), and single-weld links for greater durability and safety.

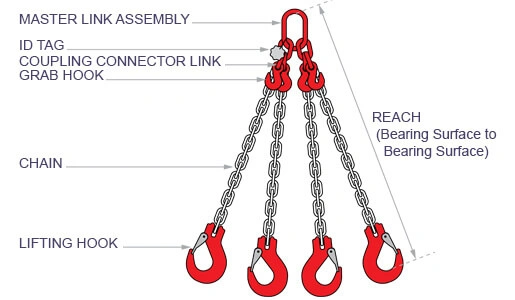

When placing an order for a custom 4 way chain sling, please keep these details in mind:

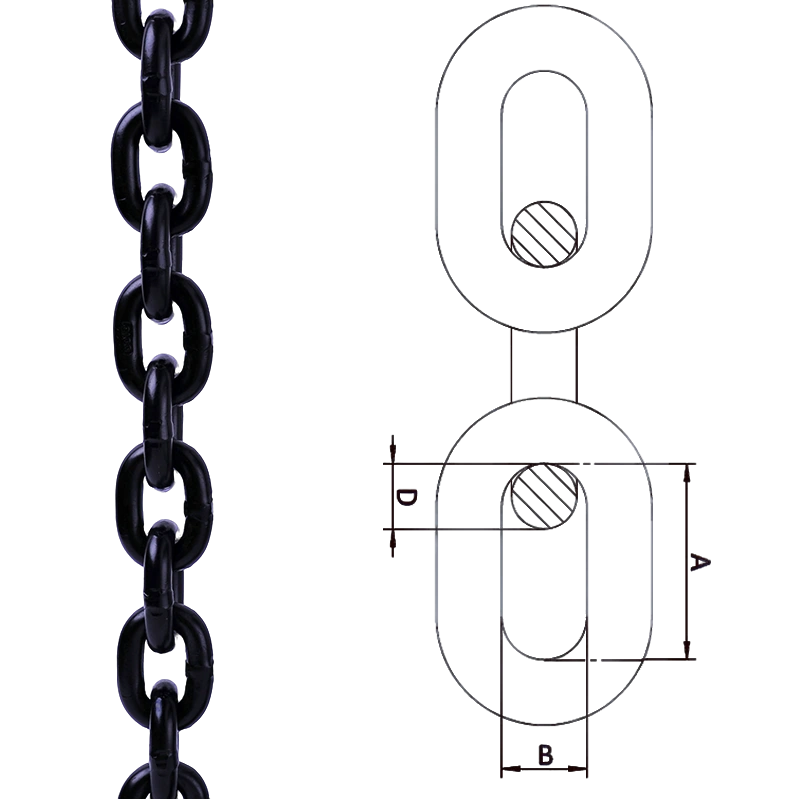

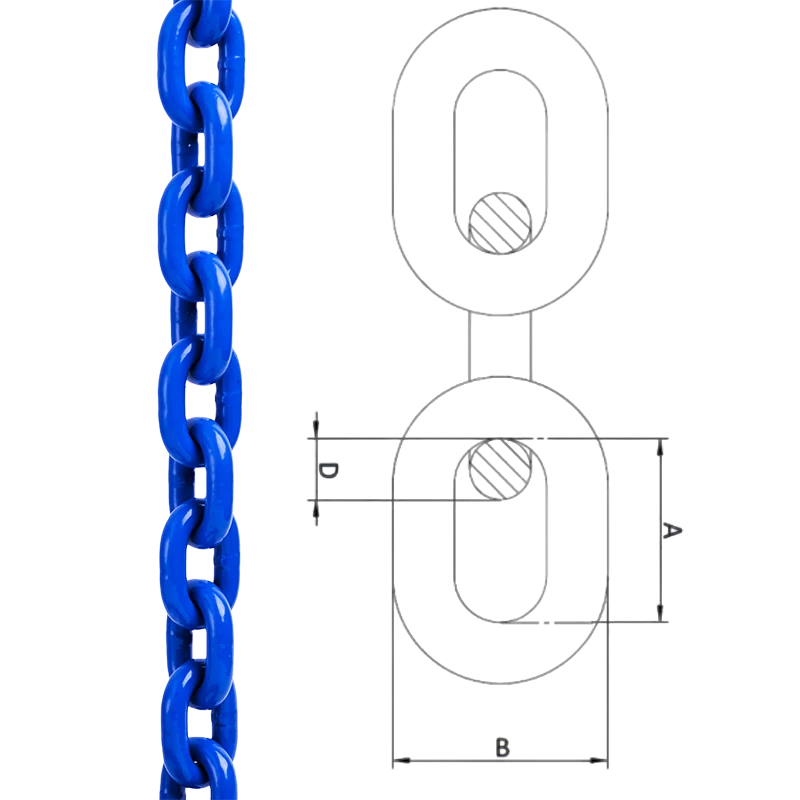

SIZE: This depends on the material size of the chain, which is determined by the working load limit you need.

REACH: Measured from bearing point to bearing point, including all attachments.

ATTACHMENTS: Standard master links are used unless specified otherwise. If you require custom master links or hooks, please provide a description or drawing.

TYPE: Select the appropriate sling type, such as:

T = Four Leg

O = Oblong Link

S = Sling Hook (if needed)

By providing these details, we ensure your 4 chain lifting sling is designed to meet your specific lifting needs, offering the strength, safety, and reliability you expect.

DESIGN

GRADE

- 100

FINISH

- Blue Powder Coat Finish

STANDARDS

- Meets or exceeds ASTM A952, NACM, & OSHA 910 Standards

- Safety factor 4:1

- Fatigue Tested at 1.5 times the WLL for 20,000 cycles

- Proof Tested at twice the WLL

HEAT TREATMENT

- Quenched and tempered before proof testing

ORIGIN

- Made in China

LINK TYPE

- Master Link

APPLICATION

- For overhead lifting

- Suited for use with wire rope, chain, and slings

MATERIAL

- Premium Fine Grain Alloy Steel

FAQ OF FOUR LEG CHAIN SLING

What is a 4 leg chain sling and when do you use it?

A 4 leg chain sling gives you four adjustable load paths from one master link. You gain load balance, control, and redundancy for complex lifts. Our customers choose this sling for oversized steel structures, machinery frames, prefast concrete, turbines, ship blocks, and mining equipment. You shorten setup time because four legs stabilize the load without extra rigging. You reduce lift rotation and edge stress.

How much does a 4 leg chain sling weigh and why does weight matter?

4 leg chain sling weight depends on chain diameter, leg length, hook type, and master link size. A 10mm Grade 80 sling weighs far less than a 16mm Grade 100 sling with clevis grab hooks. Weight affects crane capacity, rigging speed, transport cost, and worker fatigue. Smart buyers calculate sling self-weight before lift planning.

How do you calculate a 4 leg chain sling working load limit?

4 leg chain sling calculation requires sling angle, chain grade, and load symmetry. You never assume all four legs share equal load. Industry standards rate most 4 leg slings at 2-leg capacity unless geometry guarantees equal loading. We calculate using trigonometric load factors tied to the lowest sling angle.

Calculation essentials buyers must follow:

• Measure the smallest leg angle under load

• Apply angle factor to single-leg WLL

• Treat unequal loads as two-leg lifts

• Avoid angles below 45 degrees

• Document calculations for audits

What is the real price range of a 4 leg chain sling?

4 leg chain sling price changes based on material grade, chain diameter, leg length, hooks, certifications, and volume. Factory-direct pricing saves buyers margin loss from distributors. A small Grade 80 sling costs far less than a long-leg Grade 100 offshore-rated assembly.

Why do manufacturers rate many 4 leg lifting chain sling as two-leg capacity?

Load physics rarely distribute force evenly across four legs. Minor length differences or shifting centers force two legs to carry most load. Manufacturers rate conservatively to protect crews and equipment. We design leg tolerances tightly but never promise equal load share unless engineered lifting points exist.

Which chain grade works best for heavy industrial lifting?

Grade 100 chain delivers higher strength with smaller diameter compared to Grade 80. You lift more while reducing sling weight. Energy, mining, and shipyard buyers prefer Grade 100 for confined spaces and long reaches. Grade 80 still suits general construction and rental fleets.

How long does a quality 4 point chain sling last in service?

Service life depends on usage intensity, environment, inspection discipline, and overload history. Properly maintained slings last many years. Harsh conditions like saltwater, heat, or abrasive dust shorten life. We design slings for inspection access and component replacement.

Longevity strategies buyers adopt:

• Rotate slings across jobs

• Replace hooks before chain wear peaks

• Store off-ground and dry

• Track lift cycles digitally

• Reject overloaded assemblies immediately

What inspections do buyers need before each lift?

You inspect visually before every lift. You check chain elongation, cracks, gouges, hook throat opening, latch function, and tag readability. You stop use when defects appear. We stamp clear rejection criteria on tags to speed decisions.

Pre-lift inspection checklist:

• Chain link deformation

• Excessive corrosion

• Hook twist or spread

• Missing safety latches

• Illegible ID tags

Can you customize quadruple leg chain slings for special projects?

Yes. We build custom 4 leg chain slings for project-specific geometry, extreme loads, offshore rules, and government tenders. Customization improves safety and efficiency while reducing rigging improvisation onsite.