TRAWL BLOCK SPECIFICATIONS

| SIZE | S.W.L | DIAM OF ROPE |

| (IN) | (TON) | (MM) |

| 4 | 2 | 16 |

| 6 | 5 | 26 |

| 8 | 10 | 36 |

| 12 | 10 | 48 |

| 16 | 20 | 50 |

| 22 | 30 | 88 |

Powerful Machinery can supply blocks in other sizes upon request.

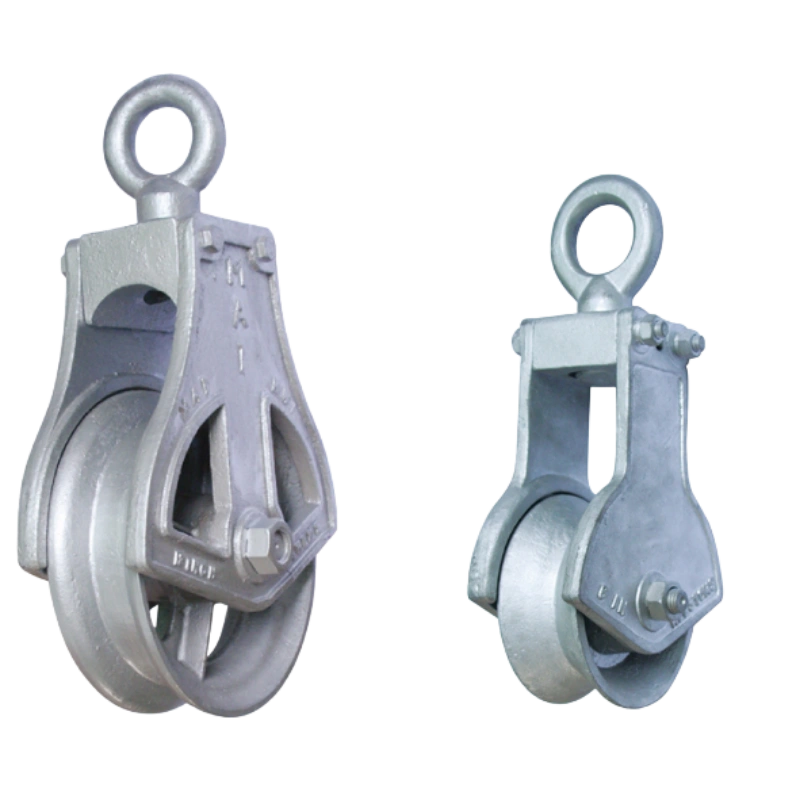

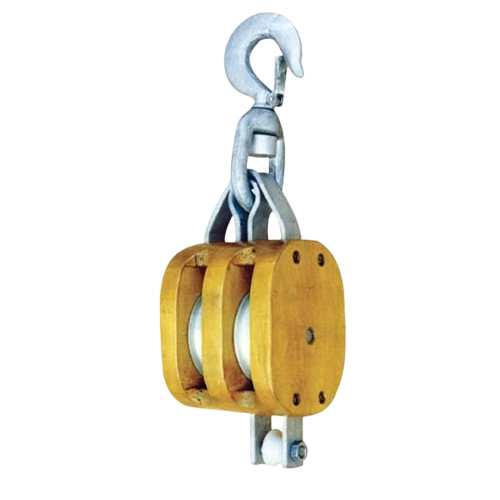

TRAWL BLOCK DESIGN

MATERIAL

- Carbon Steel/Flame-Hardened Steel

STANDARD SPECIFICATIONS

- Minimum ultimate strength 5:1

- 100% material traceability

- Sheave equipped with spherical roller bearings

- Roller Bearing Available Upon Request

- Lubrication points for all moveable parts

- End Connection Suitable for Shackle/ Hinge

FINISH

- Hot-Dip Galvanized/ Painted

STANDARDS

- The machine directive 2006/42/EC

- Bureau Veritas

- Lloyd’s Register of Shipping

- American Bureau of Shipping

- Norwegian Maritime Authority

- Det Norske Veritas

- Germanischer LLoyds

AVAILABLE OPTIONS

- Alternative sheave sizes

- Composite/stainless sheaves for rope handling

- Alternative headfitting types

INSTRUCTIONS & CAUTIONS

Check the Working Load Limit

Before using your trawl block, always verify its working load limit (WLL). Ensure that the block is rated to handle the load it will bear during your operation. Using the block beyond its WLL can lead to failure, damage to equipment, and potential accidents. If you’re ever unsure about the limits, refer to the product specifications or consult a professional.

Regular Inspection and Maintenance

Inspect your trawl block regularly, especially before and after each use. Look for wear, cracks, or corrosion on key parts like the sheave, swivel eye, and bearings. Keep all moving parts clean and lubricated to ensure smooth operation. Regular maintenance helps extend the lifespan of your equipment and reduces the risk of unexpected breakdowns in the middle of a job.

Avoid Sudden Impact or Shock Loads

Try to avoid shock loading when using the trawl block. Sudden, jerky movements can stress the block beyond its capacity and cause damage over time. Always ensure a smooth and steady load is applied to avoid unnecessary strain. Operating your block with a consistent load prevents early wear and helps keep your gear in top condition.

Protect from Corrosion

Corrosion is a major concern, especially in marine environments. After each use, rinse the trawl block with freshwater to remove salt and debris. For long-term protection, store the block in a dry area, away from extreme weather conditions. Consider using a corrosion-resistant coating or check if your block is galvanized for added protection against saltwater exposure.

OUR ADVANTAGES

Customizable to Your Needs

We offer customized trawl blocks that meet the specific demands of your operations. Whether you need a particular size, load rating, or special feature, we tailor the blocks to suit your exact requirements. No matter your operation, we provide the perfect fit for your marine and offshore needs.

Reliable, High-Quality Design

Our custom trawl blocks are made with top-grade materials, ensuring durability and reliability under tough conditions. Designed to withstand abrasive environments and high stress, they feature flame-hardened sheaves and sealed bearings to keep everything running smoothly for years, even in harsh offshore conditions.

Ready for Immediate Use

We keep Powerful Machinery Trawl Blocks in stock, so you don’t have to wait. Whether you need a quick replacement or have urgent fishing operations, our blocks are ready to ship when you need them. No delays means you can keep your marine and offshore projects running smoothly without any interruptions.

Fast and Reliable Delivery

We offer fast delivery for our trawl blocks to ensure you get them when you need them most. We understand the importance of timely deliveries, especially for fishing and construction projects that can't afford delays. Our reliable service means your equipment arrives on time and ready for use, keeping your operations running without a hitch.

OUR REVIEWS

FAQ

How should I maintain trawl blocks?

-

Regular Inspections:

Inspect your trawl blocks regularly for signs of wear, corrosion, or damage. Ensure that all components are in good working order before each use. -

Clean After Use:

After each operation, clean your blocks to remove saltwater and any debris that might have accumulated. This prevents corrosion and extends the lifespan of the block. -

Lubricate Moving Parts:

Use marine-grade grease to lubricate the moving parts, especially bearings and sheaves. This reduces friction and improves the efficiency of the block. -

Check Bearings and Sheaves:

If exposed to harsh conditions, pay extra attention to the bearings and sheaves. Look for any signs of wear or damage and replace parts as needed to ensure smooth operation.

How do I choose the right trawl block for my operation?

When selecting a trawl block, consider the working load limit (WLL), the type of operation (e.g., commercial fishing, offshore mooring), and the environment (e.g., saltwater exposure). Ensure the block is made from high-strength materials and has the necessary corrosion resistance for your specific application. If in doubt, consult our team for expert advice on the best block for your needs.

What should I do if my trawl block is damaged?

If your trawl block shows signs of significant wear, such as cracks or a damaged sheave, it’s important to replace it immediately to prevent further issues. Don’t use a damaged block, as it can cause equipment failure or accidents. Contact us for replacement parts or a new block, and always make sure to use blocks that meet the working load limit (WLL) of your operation.