RIGGING BLOCK SPECIFICATIONS

| SIZE | S.W.L | DIAM OF ROPE |

| (IN) | (TON) | (MM) |

| 2 | 0.25 | 8 |

| 3 | 0.75 | 12 |

| 4 | 1 | 14 |

| 5 | 1.5 | 16 |

| 6 | 2 | 19 |

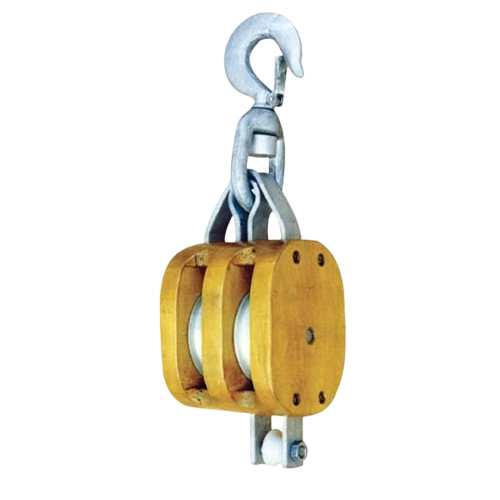

RIG BLOCKS DESIGN

MATERIAL

- Galvanized Steel

FINISH

- Lacquer Finish

STANDARDS

- ISO Standards

- American Society of Mechanical Engineers

- Det Norske Veritas

- OSHA

- EN 13157

INSTRUCTIONS & CAUTIONS

Regularly Inspect for Damage or Wear

Before each use, take a moment to check the rigging block for any signs of wear or damage, like cracks, rust, or parts that don’t move smoothly. Focus on the sheave, bearings, and swivel. A quick check can save you from bigger issues. Replace any damaged parts right away to keep everything running safely.

Ensure Proper Lubrication

Always make sure to lubricate the bearings and moving parts with marine-grade grease. This keeps friction low, helps prevent wear, and ensures smooth operation when lifting heavy loads. Forgetting to do this can lead to unnecessary damage, which could have been easily avoided.

Check Weight Capacity Before Use

Don’t skip the step of checking your rigging block’s weight capacity. Make sure it’s rated for the load you’re lifting. Overloading can put everyone at risk and damage your equipment. Stick to the working load limit (WLL), and if you’re not sure, always double-check with the manufacturer’s specifications.

Follow Manufacturer Guidelines for Installation

When installing the rigging block, make sure it’s set up exactly as the manufacturer suggests. Secure all attachments properly and make sure everything is fastened. Proper installation isn’t just about getting the job done—it’s about doing it safely. Not following the guidelines could cause the block to fail when you need it most.

OUR ADVANTAGES

Reliable Design for Tough Jobs

Our custom rigging blocks are designed for durability. Built to handle heavy loads in demanding conditions, you can rely on them for construction, marine, or industrial applications, knowing they won’t let you down.

Perfectly Fit for Your Purpose

We design custom rigging blocks to your exact specs. Whether you need a particular size, sheave type, or bearing, we ensure the block is tailored to meet your specific needs. No compromises on performance—just the right solution for your job.

Always in Stock for Quick Delivery

We keep a wide range of rigging blocks in stock, ensuring fast, hassle-free delivery when you need them most. With our ready-to-ship inventory, you can count on minimal wait times, so your project stays on track.

On-Time Delivery, Every Time

Our efficient process guarantees your custom rigging blocks will arrive as promised, on time. We understand deadlines, and we make sure you won’t face delays, helping you keep your operations running smoothly.

OUR REVIEWS

FAQ

Rigging Block vs Pulley: What is the Difference?

A rigging block and a pulley are both used to change the direction of a rope or cable, but a rigging block is typically used for heavier loads and incorporates features like bearings and a sheave to handle high stress. It’s more durable and built for heavy-duty tasks in marine, construction, or industrial settings. A pulley, on the other hand, is often used for lighter operations.

How do I set up a rigging block properly?

Setting up a rigging block requires ensuring it’s securely attached to the lifting equipment with the correct load-bearing components, such as shackles or hooks. Make sure the rope or wire is threaded through the sheave and that the block is oriented correctly to avoid any friction or binding. Always check the working load limit (WLL) and lubricate moving parts for smooth operation.

What is the advantage of using a rigging block over other lifting equipment?

A rigging block provides more control and efficiency in heavy lifting. It distributes the load evenly across the rope or cable, reducing wear and tear. The durable materials like galvanized steel and cast iron ensure long-lasting performance in tough environments. Whether in marine, construction, or industrial applications, rigging blocks ensure safer and more reliable lifting operations.

What is the working load limit (WLL) of a rigging block?

The working load limit (WLL) indicates the maximum load a rigging block can safely handle. Always ensure that the load you’re lifting is well below the WLL to prevent failure. Overloading a rigging block can cause dangerous accidents. For safety, check the manufacturer’s specifications and choose a rigging block that matches the demands of your project.

Rigging Ring vs Block: What is the Difference?

A rigging ring is typically used for attachment points where the rope or chain is connected, whereas a rigging block is designed to provide mechanical advantage by changing the direction of a rope or reducing friction. While a rigging ring is mainly a connection point, the rigging block is crucial for lifting and load distribution in heavy-duty applications.

How do I know if I need a custom rigging block?

If your project requires specific features—such as a unique size, specific sheave type, or a custom material—you may need a custom rigging block. Our custom solutions are tailored to your requirements, ensuring that the block fits the exact load, environmental conditions, and performance needs of your operation. Custom rigging blocks improve efficiency and safety.

Can rigging blocks be used with any type of rope or cable?

Rigging blocks are designed to work with a range of ropes, cables, and chains, but it’s important to choose the right block for your rope type. For steel ropes, choose a block with a suitable sheave size and bearing system that can handle the load. Always match the block to the rope’s diameter and material to ensure proper functioning.

How should I store rigging blocks when not in use?

Store rigging blocks in a dry, cool place to prevent corrosion or damage from the elements. If stored in marine environments, ensure the blocks are cleaned and lubricated before storage to prevent salt buildup. Avoid storing them in areas where they may be exposed to extreme heat, moisture, or excessive wear.