Product Specifications

| DECK LASHING TURNBUCKLE | ||||

| SIZE | W.L.L. | MAX.LENGTH | MIN.LENGTH | N.W. |

| inch | ton | mm | mm | KG/PC |

| 1-1/4X18 | 25.50 | 1775 | 1270 | 16.80 |

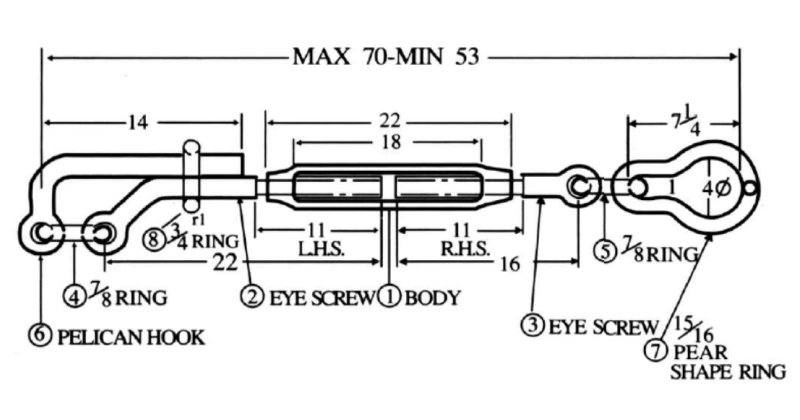

Products Diagrams

The threaded body, end fittings, and lock nuts of the Deck Lashing Turnbuckle show how it evenly distributes tension and ensures safe and adjustable lashing in marine cargo operations.

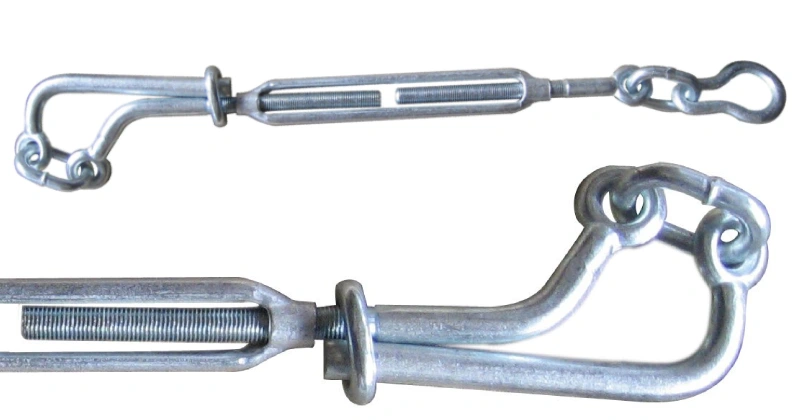

The Deck Lashing Turnbuckle is integrated with deck lashing chains and D-rings, emphasizing its role in tightening and stabilizing containers and heavy loads aboard ships and transport platforms.

Material Specification

Grade:

Manufactured from high-tensile steel Grade 8.8 for superior load-bearing strength and reliable long-term performance in heavy-duty lashing applications.

Finish:

Hot-dip galvanized or zinc-plated to ensure exceptional resistance to saltwater corrosion and harsh marine conditions.

Attachment:

Features open or closed hooks and eyes for flexible deck connections, allowing secure and adjustable linkage to chains or wire ropes.

Hook Type:

Equipped with forged hooks or turnbuckle eyes, offering strong grip and easy rotation for precise tension adjustments.

Material:

Crafted from alloy steel or carbon steel, precision-machined and heat-treated to balance strength, ductility, and resistance to wear.

Application

Construction Industry

Used to stabilize scaffolding and secure heavy loads during transport, ensuring structural integrity at construction sites.

Marine & Offshore

Ideal for securing deck cargo, containers, and equipment in harsh sea conditions, ensuring reliable tension and stability.

Mining Industry

Applied in heavy equipment transport and anchoring operations, keeping machinery safely fastened during hauling or setup.

Advantages

Corrosion & Finish Protection

Galvanized coating ensures rust resistance and extends service life even in coastal and offshore environments.

Customization & Traceability

Custom sizes, finishes, and batch traceability ensure every turnbuckle meets exact project or OEM standards.

Load Control & Durability

Strong threaded design enables precise tensioning and reliable control under dynamic load conditions.

Bulk Capacity & Lead Time

We support high-volume orders with consistent quality, stable supply, and short manufacturing lead times.

What Our Clients Say

FAQ

What is a Deck Lashing Turnbuckle used for?

It’s used to apply and maintain tension in deck lashing systems, securing cargo or containers aboard ships. Its adjustable threaded design allows precise tightening, ensuring loads remain stable and safe throughout transport.

What materials are your turnbuckles made from?

We use premium carbon and alloy steels that undergo forging and heat treatment for strength and durability. All surfaces are galvanized or zinc-coated for superior corrosion protection.

Can I order customized Deck Lashing Turnbuckles?

Yes, Powerful Machinery offers full customization—choose your size, finish, thread type, or end fitting to match your project requirements. OEM and branding services are available for distributors.

How do I ensure proper tension adjustment?

Always use a spanner or wrench to rotate the turnbuckle body evenly. Avoid over-tightening. Regularly inspect threads and pins for corrosion or wear to maintain optimal performance.

What’s your production capacity and lead time?

We maintain large inventory and advanced automated production lines. Standard orders ship in 2–4 weeks, while custom designs may take 3–5 weeks depending on complexity.

Do you provide testing certificates?

Yes. All Deck Lashing Turnbuckles are supplied with material, proof load, and breaking load certificates to ensure compliance with international standards.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.