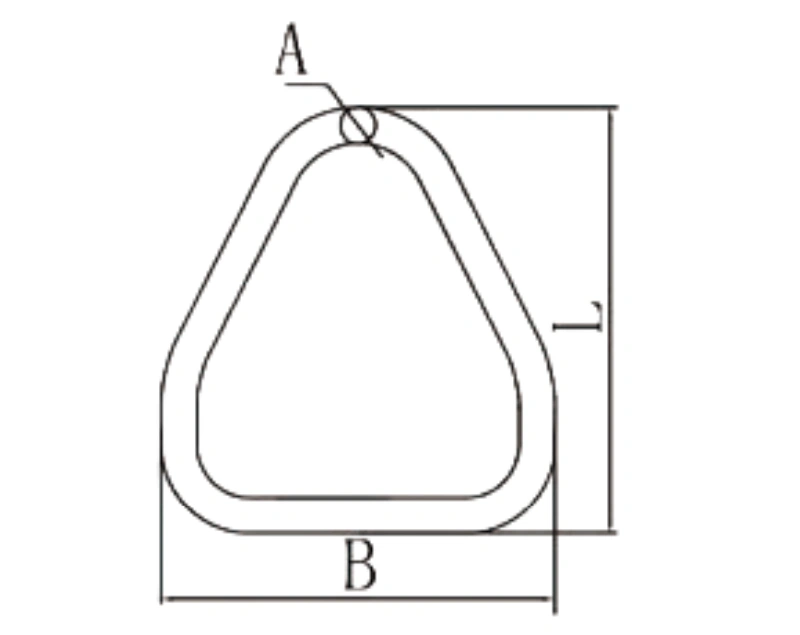

WELDED TRIANGLE RINGS DIAGRAM

WELDED TRIANGLE RINGS SPECIFICATIONS

| Item No. | WEIGHT/kg | WLL/T | B.L/T | A | B | L |

| CLATR2 | 0.81 | 2 | 8 | 16 | 145 | 194 |

| CLATR3 | 1.66 | 3 | 12 | 20 | 199 | 248 |

| CLATR4 | 2.25 | 4 | 16 | 22 | 243 | 260 |

| CLATR6 | 4.94 | 6 | 24 | 28 | 340 | 340 |

WELDED TRIANGLE RING INFORMATION

Material and Durability

The welded triangle ring is made from super alloy steel, which is forged, quenched, and tempered for exceptional strength and durability, ideal for heavy-duty lifting tasks.

Safety and Testing

-

Breakage test: The ring undergoes rigorous breakage testing to ensure its strength under load.

-

Fatigue Testing: It is fatigue-tested at 1.5 times the Working Load Limit for 20,000 cycles, guaranteeing long-lasting performance in demanding conditions.

-

Proof Testing: Each ring is proof-tested at 2.5 times the Working Load Limit to verify its capacity and safety.

Quality Assurance

Magnaflux Crack Detection: The welded triangle ring is 100% magnaflux crack detected, ensuring there are no hidden defects and guaranteeing safe operation.

Surface Protection

The surface of the triangle ring is powder-coated to provide enhanced corrosion resistance, making it suitable for various environmental conditions, including outdoor and marine settings.

Compatibility

The welded triangle ring is specifically designed for use with web slings and G80 chains (EN818-2), providing a secure and reliable connection for lifting operations.

INSTRUCTIONS & CAUTIONS

Inspect Before Each Use

Before using the alloy triangle ring, the operator must perform a thorough safety inspection. Check for any visible damage or wear on the ring and web sling. Only proceed with lifting operations if the equipment is in optimal condition and meets safety standards. Safety first — never take shortcuts when it comes to lifting.

Regular Professional Inspections

The alloy triangle ring should be inspected regularly by qualified professionals. A monthly check by trained personnel ensures that the equipment is safe and functions as expected. Professional inspections help identify any wear or fatigue that could compromise the lifting operation. Always ensure the equipment is up to standard before use.

Check for Dimensional Wear

If the alloy triangle ring or sling shows dimensional wear greater than 5% of its original size, it must be replaced immediately. This level of wear can reduce the strength and safety of the sling, making it unsuitable for lifting. Ensure that regular checks are done to avoid any risks during lifting operations.

Monitor for Deformation

If you notice dimensional deformation of the alloy triangle ring exceeding 3% of the original size, it must be replaced as soon as possible. Deformation compromises the structural integrity of the equipment, and using deformed equipment could lead to failure. Prioritize safety by replacing any compromised parts promptly.

OUR ADVANTAGES

Custom-Engineered Solutions

Need tailored solutions? We offer custom-engineered products to meet your specific needs. From special load capacities to custom designs, we work closely with you to ensure your lifting equipment fits your exact requirements. No matter the challenge, we’re ready to provide innovative solutions that improve your operations and help you stay ahead in the industry.

One-Stop Sourcing Solution

We provide a one-stop sourcing solution, saving you time and effort. Whether you need lifting accessories, slings, or hooks, we offer a wide range of products, all available from a single supplier. This simplifies your procurement process, reduces lead times, and streamlines your supply chain. You can rely on us for consistency and efficiency in sourcing your lifting equipment.

Commitment to Quality & Safety

At Powerful Machinery, we prioritize quality and safety above all else. Our products undergo strict testing and adhere to industry standards, ensuring reliability and durability. When you partner with us, you're assured of products that are built to perform and keep your operations safe. Trust us to deliver top-tier lifting equipment that meets your rigorous demands.

Superior After-Sales Service

At Powerful Machinery, our support doesn't end after the sale. We offer industry-leading after-sales service to ensure you get the most out of your equipment. From training to maintenance advice, our team is always ready to assist. With us, you gain a long-term partner who’s committed to your success and operational efficiency.

FAQ

What is an alloy welded triangle ring for web sling?

An alloy welded triangle ring for web sling is a high-strength, durable component designed to connect web slings to lifting equipment. Made from super alloy steel, it ensures secure and reliable lifting operations. The welded design offers additional strength, making it ideal for heavy-duty lifting tasks in industrial settings. It’s a vital part of any lifting rigging system.

How do I select the right size alloy welded triangle ring?

-

Check the Working Load Limit (WLL)

-

Ensure the Working Load Limit (WLL) of the alloy welded triangle ring matches the weight and load capacity of your lifting equipment. The WLL is a key factor in selecting the right ring for safe lifting operations.

-

-

Consider the Diameter of the Web Sling

-

The diameter of the web sling is crucial when selecting the correct ring. Make sure the ring fits the sling’s size to ensure a secure and safe connection.

-

-

Understand the Lifting Application

-

Take into account the type of lifting application, whether it’s for construction, industrial, or other heavy-duty tasks. Different applications may require specific specifications for optimal safety and efficiency.

-

-

Need Assistance? Contact Us

-

If you’re unsure about the right size, don’t hesitate to contact us. We can provide expert guidance to help you select the perfect alloy welded triangle ring for your lifting needs.

-

How do I place an order for alloy welded triangle rings?

-

Contact Our Sales Team

-

To place an order for the alloy welded triangle ring, simply contact our sales team. We’re ready to discuss your specific requirements.

-

-

Discuss Your Requirements

-

We will talk through key details such as quantity, size, and any customizations you may need. We’ll ensure the ring is tailored to your lifting needs.

-

-

Competitive Pricing

-

Enjoy competitive pricing on all our products, ensuring you get top-quality equipment at the best possible value for your business.

-

-

Reliable Delivery

-

We guarantee reliable delivery so you can count on your order arriving on time, every time, for smooth operations.

-

-

Guidance Through the Process

-

Our team will guide you through the entire ordering process, from selecting the right product to finalizing the purchase, ensuring you get exactly what you need.

-

What is the expected lifespan of the alloy welded triangle ring?

The lifespan of the alloy welded triangle ring depends on the frequency of use, load conditions, and maintenance. With proper care and regular inspections, it can last for many years, even in harsh environments. Always replace the ring if any signs of wear, corrosion, or damage are found to ensure continued safety and performance.