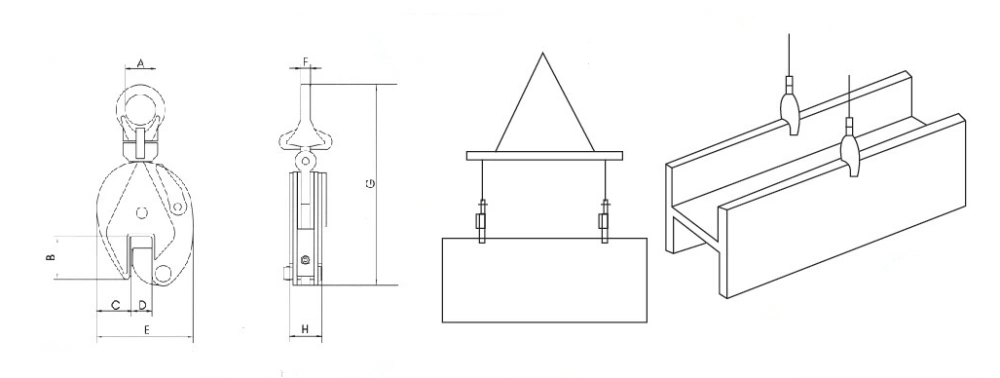

VERTICAL PLATE LIFTING CLAMP DRAWING

VERTICAL PLATE LIFTING CLAMPS SPECIFICATIONS

| Model | 0.5 T | 1T | 2T | 3T | 5T | |

| Capacity(kg) | 500 | 1000 | 2000 | 3000 | 5000 | |

| Running test load(kN) | 7.35 | 14.7 | 29.4 | 44.1 | 73.5 | |

| Max.Jaw Opening(mm) | 15 | 20 | 25 | 30 | 50 | |

| Dimensions(mm) | A | 30 | 48 | 68 | 74 | 80 |

| B | 43 | 63 | 76 | 85 | 90 | |

| C | 34.5 | 51 | 59 | 56 | 65 | |

| D | 0-17 | 0-22 | 0-27 | 0-32 | 0-52 | |

| E | 103 | 138 | 164 | 193 | 240 | |

| F | 10 | 12 | 16 | 20 | 22 | |

| G | 212 | 294 | 370 | 418 | 450 | |

| H | 36 | 50 | 52 | 78 | 88 | |

| Net weight(kg) | 2 | 4.8 | 6.8 | 15 | 23 | |

| Volume(cm) | 23 x 5 x 11.5 | 37 x 7 x 16 | 38 x 8 x 9 | 45 x 11 x 22 | 46 x 11 x 22 | |

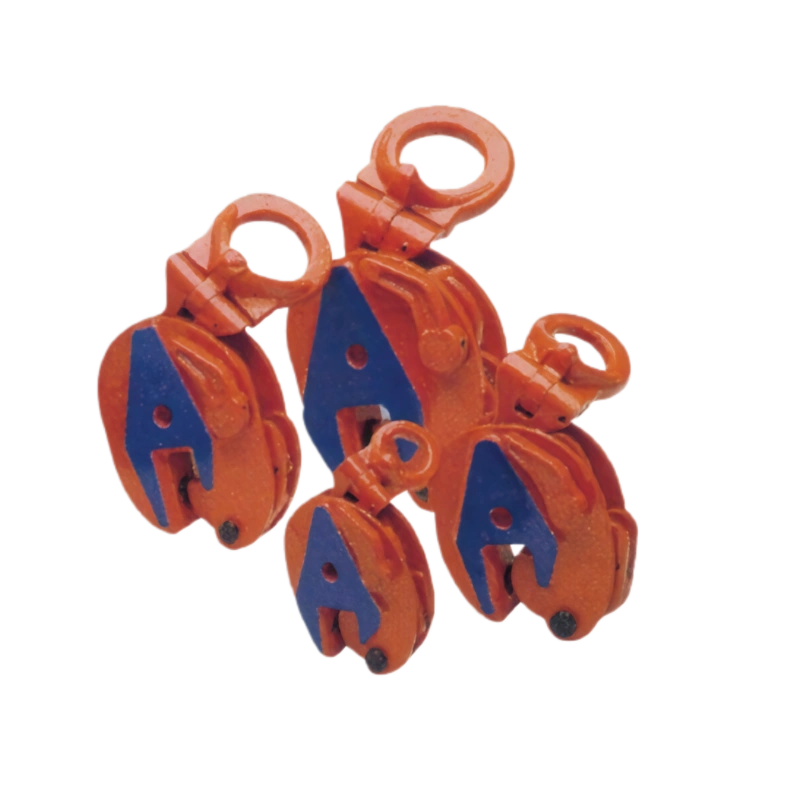

VERTICAL PLATE CLAMPS FEATURES

Load Capacities

The QC-A vertical plate clamps are available in 1/2T, 2T, 3T, and 5T capacities, making them suitable for lifting and moving steel plates in a vertical position across various industrial applications.

Safety Rating

These clamps provide a 4:1 safety factor, ensuring that they can safely handle loads significantly higher than their rated capacity, which guarantees secure lifting operations.

Self-Locking Mechanism

Designed with a self-locking device, the vertical plate clamp ensures a tight grip on steel plates, preventing slippage during lifting. This added security improves safety and efficiency.

Ergonomic Design

Featuring a hinged handle, these clamps are easy to handle and operate. The ergonomic design enhances user control and reduces the risk of accidents during lifting, making the process safer and more efficient.

INSTRUCTIONS & CAUTIONS

Verify Load Weight and Capacity

Before using the clamp, double-check that the weight of your load matches the clamp’s rated capacity. Vertical plate clamps come in different sizes (1/2T to 5T), so it’s essential to match the clamp’s WLL (working load limit) with your load. If you’re unsure about the weight, reach out to us, and we’ll help you select the right clamp.

Ensure Proper Attachment

Always ensure the clamp is securely attached to the steel plate before lifting. The self-locking mechanism should be fully engaged, and the clamp should sit tightly on the plate. A poorly secured clamp can result in slippage or accidents, so take extra care to check that it’s properly fastened before lifting.

Avoid Impact During Lifting

When lifting, avoid any impact or collision with other objects. Bumping or striking the load could compromise the clamp’s grip and cause potential damage. Move the load carefully, ensuring smooth, controlled lifting to maintain safety and minimize risks.

Regular Inspection and Maintenance

Make regular inspections a habit. Look for any signs of wear, cracks, or damage on the clamp. Regular maintenance, such as lubricating moving parts, will help extend the life of the clamp and ensure it works properly. Need guidance on maintenance? Get in touch with us for detailed instructions.

OUR ADVANTAGES

Custom-Engineered Solutions

We understand that each business has unique needs. That's why we offer custom-engineered solutions tailored specifically to your lifting requirements. Whether you need specialized equipment or unique modifications, our team works closely with you to develop products that meet your exact specifications and help optimize your operations.

One-Stop Sourcing Solution

We offer a comprehensive range of lifting equipment and services, providing a one-stop sourcing solution for all your lifting needs. From initial consultation to delivery and installation, we manage the entire process to ensure efficiency and reduce your operational complexity. This saves you time and simplifies procurement, making us your go-to partner for all lifting equipment.

Quality & Safety First

At Powerful Machinery, we prioritize quality and safety above all else. Our products are engineered to meet rigorous industry standards, ensuring reliability and durability. We focus on providing lifting equipment that exceeds safety requirements, so you can trust that every job will be completed with maximum security for your team and equipment.

Competitive Pricing & After-Sales Service

We combine competitive pricing with exceptional after-sales support. Our customers benefit from high-quality equipment at the best value, backed by ongoing technical support and maintenance services. Whether you need product guidance, troubleshooting, or repairs, our team is dedicated to ensuring your equipment runs smoothly long after purchase.

FAQ

How do I choose the right vertical plate clamp for my load?

-

Match WLL to Load Weight

Ensure the working load limit (WLL) of the clamp is equal to or exceeds the weight of your load. Selecting the correct capacity is critical for safe lifting. -

Consider the Material

Take into account the material you’re lifting, whether it’s steel, aluminum, or another type. Different clamps are designed for specific materials, so choose accordingly. -

Account for Special Conditions

Consider any special conditions, such as temperature extremes, moisture, or corrosive environments. These factors may require a more durable or specialized clamp. -

Get Expert Assistance

If you’re unsure which clamp is best suited for your load and environment, our team is here to help. We offer personalized guidance to ensure you choose the right clamp for your specific needs.

Are vertical plate clamps suitable for both vertical and horizontal lifting?

While vertical plate clamps are mainly designed for vertical lifting, some models can also handle horizontal lifting. If your project requires both orientations, let us know, and we’ll recommend the best clamp for your needs.

What happens if I exceed the WLL of a vertical plate clamp?

Exceeding the WLL can lead to clamp failure, damaging both the load and the equipment. Always ensure the clamp’s capacity matches your load. Overloading can compromise the clamp’s safety features and cause serious risks. If you’re unsure, our team can help you determine the right clamp for your load.

What should I do if the clamp is damaged?

If you notice any damage, such as cracks or wear, stop using the clamp immediately. Do not attempt to lift with a damaged clamp. Contact us for repair or replacement options, and we’ll guide you through the process to ensure safe and efficient lifting.

Are vertical plate clamps covered under warranty?

Yes, vertical plate clamps typically come with a warranty that covers manufacturing defects. Warranty coverage may vary by model, so contact us for full details and to register your clamp for warranty protection.

What should I do if the clamp doesn’t grip the load properly?

If the clamp is not gripping properly, stop lifting immediately. Check if the self-locking mechanism is engaged, and ensure the clamp is correctly positioned. If the issue persists, contact us for troubleshooting or consider using a different model better suited for your load.

How long will it take to receive my vertical plate clamp order?

Standard orders usually ship within a few days, but custom orders may take longer. Shipping times depend on your location and the specific product. Contact us with your details, and we’ll provide a more accurate delivery estimate for your order.