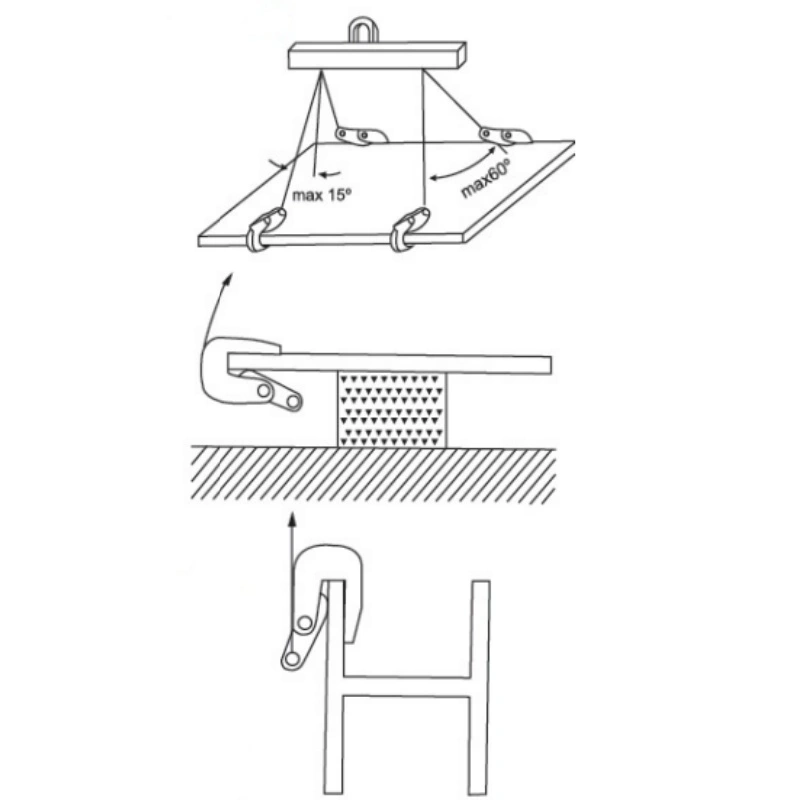

HORIZONTAL PLATE LIFTING CLAMP DRAWING

HORIZONTAL PLATE CLAMPS SPECIFICATIONS

| Model | Capacity (ton) | Opening size(MM) | Dimensions(mm) | Net weight (KG) | ||||||||||

| L | t | T | H | h1 | h2 | B | b1 | b2 | D | d | ||||

| HLC-1 | 1000 | 1-13 | 173 | 14 | 32 | 104 | 23.5 | 39.5 | 105 | 66 | 44 | 72 | 46 | 1.6 |

| HLC-2 | 2000 | 3-22 | 233 | 18 | 42 | 130 | 36 | 50 | 137 | 87 | 58 | 96 | 61 | 3.9 |

| HLC-3 | 3000 | 12-35 | 261 | 23 | 52 | 177 | 42 | 67.5 | 173.5 | 107 | 68 | 80 | 35 | 9 |

HORIZONTAL PLATE LIFTING CLAMPS FEATURES

Versatile Capacity

Our horizontal plate clamp comes with standard capacities, with higher options available upon request. This flexibility ensures we can meet a wide range of lifting requirements for your business.

Ideal for Horizontal Plate Lifting

Engineered specifically for horizontal plate lifting, this clamp ensures a secure, stable hold on your materials, making it ideal for industries handling large, heavy steel plates.

Easy Installation in Tight Spaces

The clamp is designed for easy installation with minimal headroom, making it a practical solution for use in tight or confined spaces without additional setup requirements.

Strong All-Steel Construction

Built with durable all-steel construction, the horizontal plate clamp guarantees long-lasting strength and safe operation in even the most demanding lifting environments.

Compact & Lightweight

This clamp’s compact design and lightweight build allow for effortless handling, improving operational efficiency and reducing operator fatigue.

Enhanced Safety Locking Mechanism

The built-in locking mechanism provides added safety, preventing the accidental release of the load and ensuring safer operations for your team.

Easy-to-Replace Parts

Parts of the clamp are easily replaceable, ensuring minimal downtime and allowing for continued use with minimal disruption to your workflow.

Low Maintenance Design

Designed for low maintenance, this clamp minimizes the need for frequent upkeep, allowing your business to operate smoothly with reduced maintenance costs.

INSTRUCTIONS & CAUTIONS

Match the WLL with the Load Weight

Always ensure the working load limit (WLL) of the clamp matches or exceeds the weight of the load you are lifting. Using a clamp with too low a WLL can lead to failure and pose serious safety risks. If you’re unsure which clamp suits your load, don’t hesitate to reach out for advice from our team. We’re happy to guide you in selecting the right one.

Securely Position and Attach the Clamp

Before lifting, double-check that the clamp is properly positioned and securely attached to the load. Incorrect positioning or loose attachments can cause slippage or accidents. Proper attachment is crucial for safe lifting. Need help with positioning? Contact us for step-by-step instructions or setup advice to ensure you’re lifting safely and efficiently.

Avoid Impact and Bumping During Lifting

When moving the load, always ensure it is lifted smoothly. Avoid bumping or hitting the load against other objects, as this can damage both the clamp and the material. Moving the load gently reduces risks and helps extend the lifespan of your equipment. If you need tips on handling or lifting safely, our experts are here to assist you.

Inspect the Clamp Regularly for Wear and Damage

Regularly inspect your horizontal plate clamp for signs of wear, cracks, or any other damage. A damaged clamp can compromise the safety of the lift. Replace worn parts immediately to prevent accidents. For guidance on inspection or ordering replacement parts, reach out to us for advice or assistance.

OUR ADVANTAGES

Tailored Solutions for Your Needs

At Powerful Machinery, we focus on providing customized solutions to meet your specific lifting requirements. Whether you need unique configurations, capacities, or features, we work closely with you to deliver equipment that fits your needs perfectly. Our dedicated team ensures that every project is completed with attention to detail and efficiency.

Competitive Pricing Without Compromising Quality

We offer high-quality lifting equipment at competitive prices. By maintaining a balance between cost-efficiency and reliability, we help our customers access top-tier products without exceeding their budget. You get durable, efficient equipment backed by excellent service, all at a price that makes sense for your business.

Fast and Flexible Delivery Options

We understand that time is critical in your operations, which is why we offer fast and flexible delivery options. Whether you need products delivered quickly to meet tight deadlines or require customized shipping solutions, we’re committed to getting your orders to you as quickly and efficiently as possible.

Reliable After-Sales Support

We stand by our products with reliable after-sales support. If you need assistance, whether it’s maintenance advice, troubleshooting, or technical support, our team is here to help. Our goal is to ensure your equipment operates at peak performance, long after the sale, so you can focus on running your business smoothly.

FAQ

How do I choose the right horizontal plate clamp for my load?

-

Match WLL with Load Weight

Ensure that the working load limit (WLL) of the clamp is equal to or greater than the weight of the load you’re lifting. This is the most important factor for safety. -

Consider the Material Type

The type of material you are lifting—whether steel, aluminum, or another—may influence the clamp you need. Each material might require specific configurations. -

Factor in Environmental Conditions

Environmental factors such as high temperatures, moisture, or corrosive conditions can affect the clamp’s performance. Choose a clamp designed to handle these conditions for optimal safety and durability. -

Get Expert Assistance

If you’re unsure which clamp is right for your application, our team of experts is here to help. Contact us, and we’ll guide you in selecting the perfect horizontal plate clamp for your needs.

Can horizontal plate clamps lift in both directions?

Horizontal plate clamps are specifically designed for horizontal lifting, but some models are versatile enough for both horizontal and vertical lifting. Let us know if your project requires both, and we’ll suggest the right clamp for your needs.

What materials can horizontal plate clamps handle?

Our clamps are designed for steel plates but can also handle other materials like aluminum or concrete. Check the product specifications or contact us to confirm if your material is suitable for the clamp you’re considering.

Are horizontal plate clamps covered by a warranty?

Yes, all our horizontal plate clamps come with a warranty that covers manufacturing defects. If you encounter any issues, simply contact us for assistance with repairs or replacements. Warranty terms vary, so reach out for more details.

Can I order replacement parts for my horizontal plate clamp?

Yes, we offer a full range of replacement parts for our horizontal plate clamps. Whether you need new jaws, springs, or other components, we’ve got you covered. Contact us to order the parts you need, and we’ll make sure you get the right fit.

How long does it take to receive my horizontal plate clamp order?

Standard orders typically ship within a few days, while custom orders may take a bit longer. Shipping times depend on your location and the specific clamp model. Reach out to us with your order details, and we’ll provide an accurate delivery estimate.